Casting mold cleaning device for steering knuckle processing

A technology for casting molds and cleaning devices, which is applied to the cleaning method of tools, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the difficulty in controlling the cleaning time of electrolyte alkali concentration, temperature, and current density, and accelerate the fouling of casting molds Problems such as quick detachment and low cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

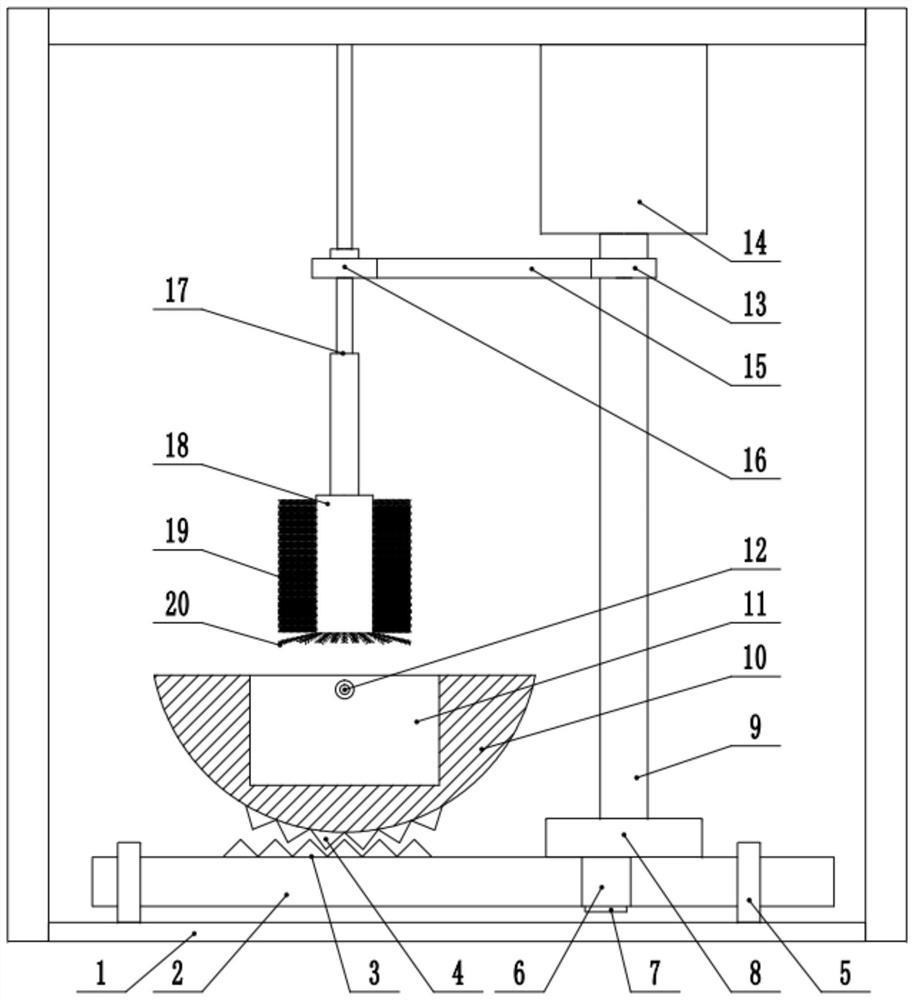

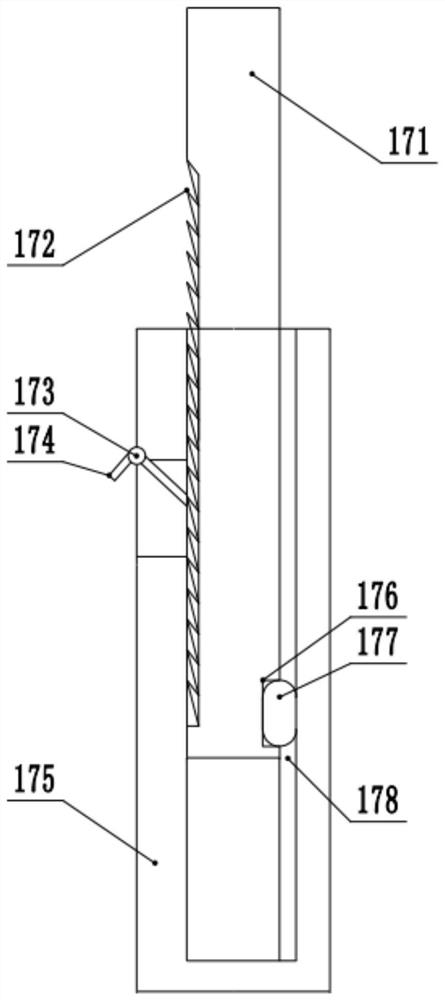

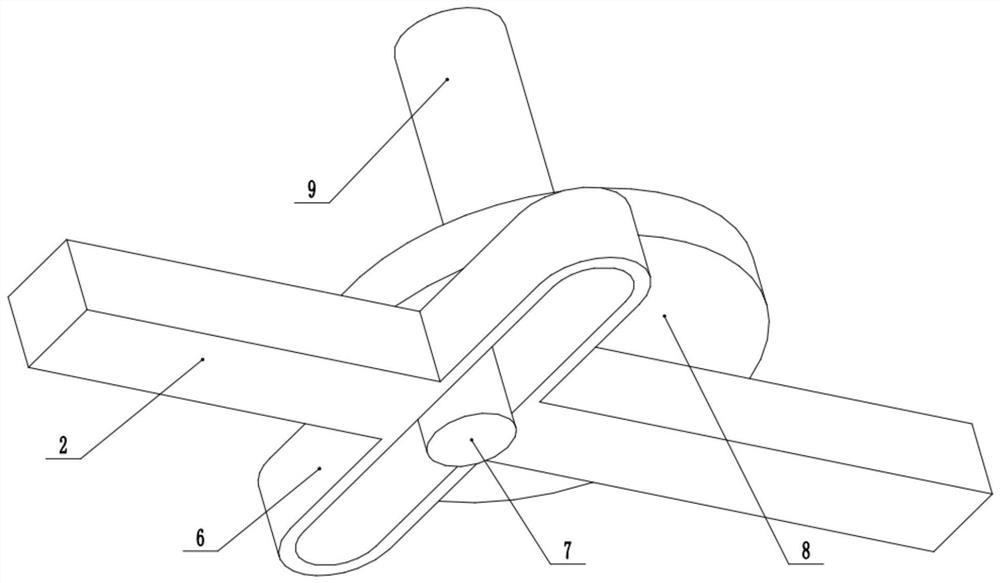

[0024] refer to Figure 1~3 , in an embodiment of the present invention, a casting mold cleaning device for steering knuckle processing includes a motor 14, an output shaft 9 is installed on the lower end of the motor 14, a disc 8 is installed on the bottom end of the output shaft 9, and a disc 8 is installed on one side of the lower end of the disc 8. The rotating cylinder 7 is connected with the hollow frame 6 in contact with the rotating column 7, and the traversing rod 2 is installed on the outside of the hollow frame 6, and at least two active teeth 3 are fixed on the upper end of the traversing rod 2, and the active teeth 3 are meshed with the passive teeth 4, and the passive teeth 4. A semicircular body 10 is fixed on the upper end, and an active spur gear 13 is installed on the middle and upper part of the output shaft 9. The active spur gear 13 is connected to a passive spur gear 16 through a closed rack 15, and a telescopic device 17 is installed on the lower end of t...

Embodiment 2

[0028] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that, both sides of the base 1 are fixed with vertical fixing rods, and the upper ends of the fixing rods on both sides pass through Upper frame connects, and upper frame lower end right side is fixed with motor 14, and upper frame lower end left side is equipped with connecting rod, and connecting rod lower end is equipped with passive spur gear 16 by bearing, is used for fixing motor and driven gear.

[0029] The working principle of the present invention is: put the mold into the square groove 11 and fix it, adjust the positional relationship between the first rod body 171 and the second rod body 175 through the fixed paddle 174, so that the bottom cleaning brush 20 is close to the bottom of the mold, and then the motor 14 After electrification, the output shaft 9 is driven to rotate, and the disc 8 at the bottom of the output shaft 9 drives the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap