Vacuum drying device and method of mesh belt type ultrasonic washing machine

A vacuum drying device and mesh-belt technology, applied in cleaning methods and appliances, dryers for stationary materials, cleaning methods using liquids, etc., can solve problems such as difficult discharge of workpieces, reduced work efficiency, and easy drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

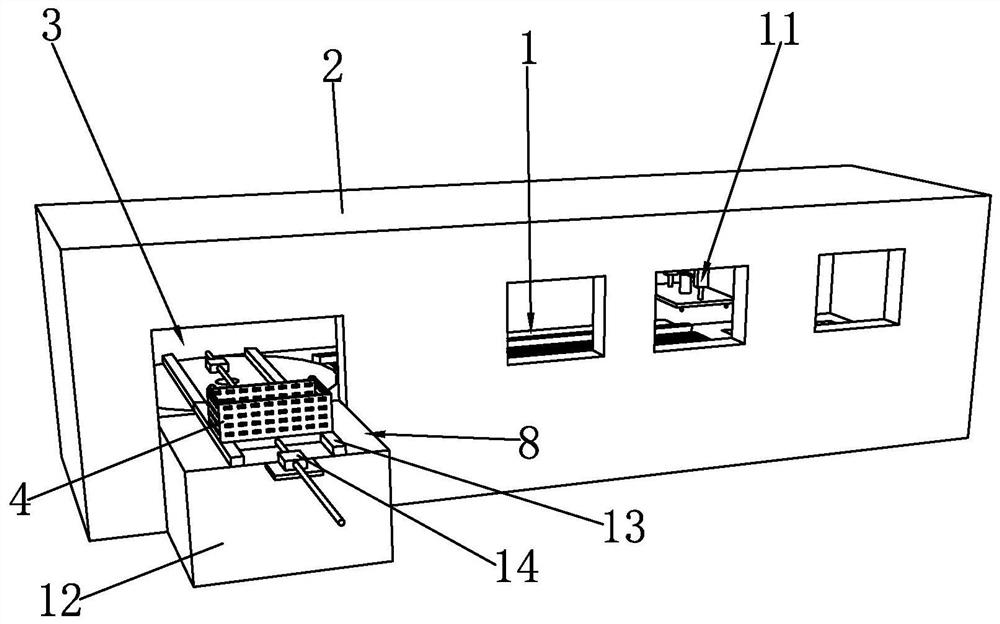

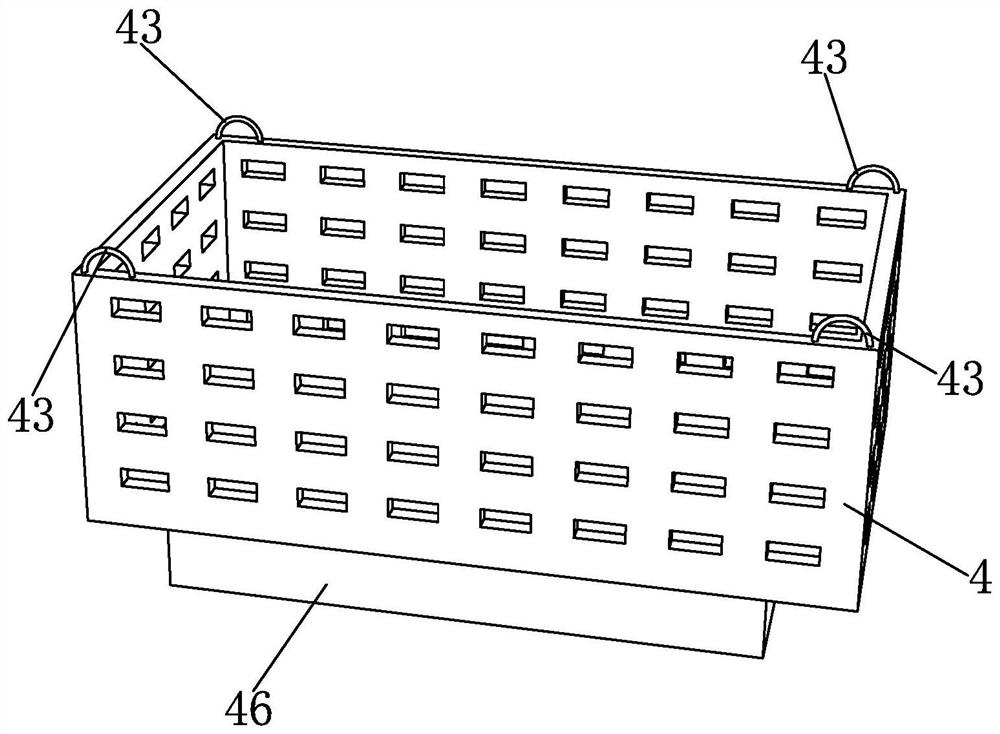

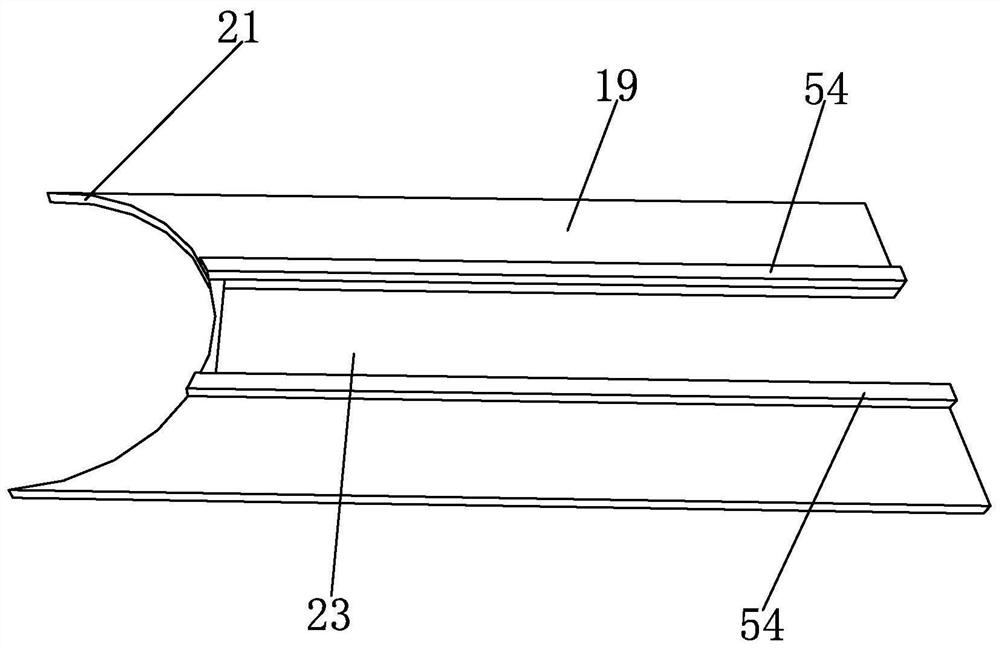

[0052] Such as Figure 1 to Figure 8 Shown is the vacuum drying device of the mesh belt type ultrasonic cleaning machine of the present invention, the vacuum drying device is arranged on the body 1 of the mesh belt type ultrasonic cleaning machine, the body 1 is provided with a cleaning section, and the body 1 is provided with a casing 2, The transmission mechanism 3 and the hollow-out placement basket 4, the placement basket 4 is used to hold the workpieces to be cleaned, the transmission mechanism 3 is used to transport the placement basket 4, the vacuum drying device is connected with the cleaning section through the transmission mechanism 3, and the vacuum drying device includes The downwardly recessed working tank 5, the working tank 5 matches the placement basket 4, the top of the working tank 5 is provided with a sealing door panel 6, the sealing door panel 6 is provided with an opening and closing assembly 7, and the opening and closing assembly 7 matches the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com