Screw motor rotor surface dressing device and machining method thereof

A rotor surface, screw motor technology, applied in the direction of coating, etc., can solve the problems of short service life, prone to sparks, wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

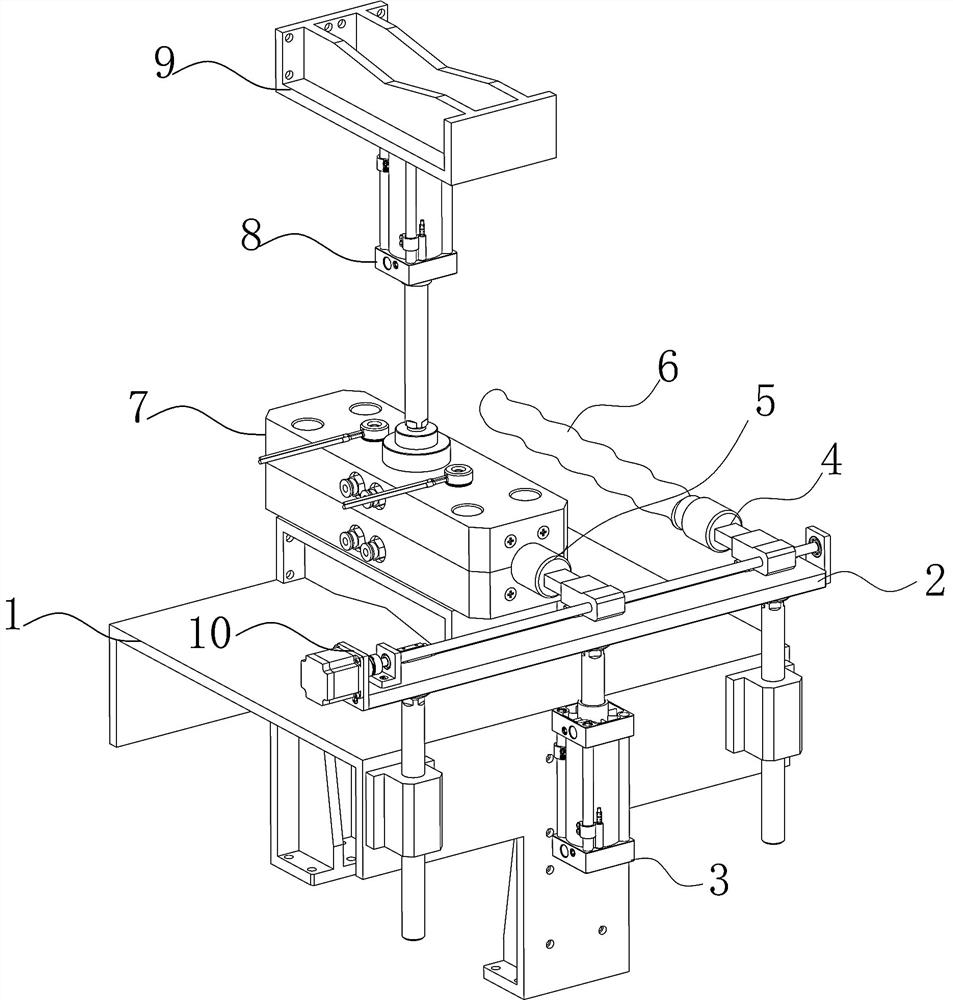

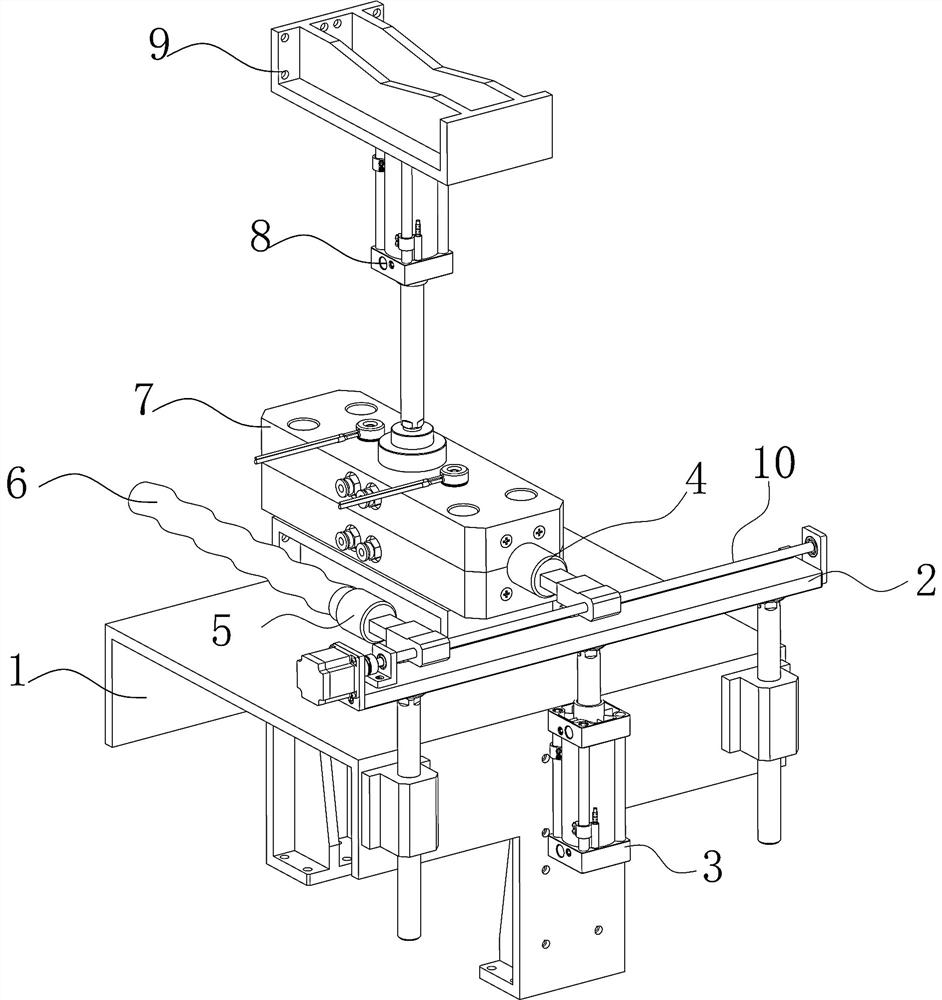

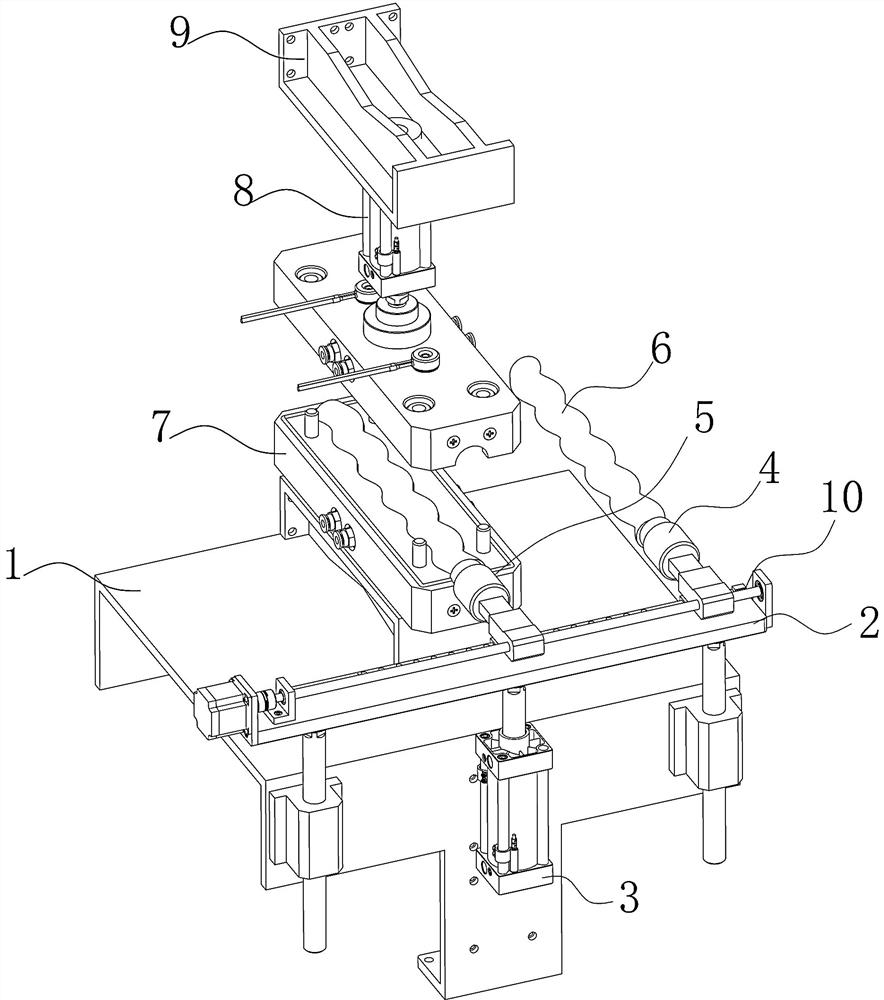

[0046] like Figure 1~11As shown, a screw motor rotor surface dressing device includes a dressing mold 7, the dressing mold 7 includes an upper mold plate 702 and a lower mold plate 703, the upper mold plate 702 and the lower mold plate 703 are provided with a groove body, and the rotor 6 is arranged in the groove body Inside, a hot runner 701 is provided above the upper template 702, and the hot runner 701 communicates with the tank body. With this structure, the upper template 702 and the lower template 703 form the cavity of the dressing, and there is a certain distance between the cavity and the rotor 6. Due to the flow of vulcanized rubber or thermosetting resin, the upper template 702 and the lower template 703 are also provided with exhaust air. The gap of the vent hole and the vent hole should be smaller than the plastic overflow value, and the hot runner 701 is used to transport the vulcanized rubber thermosetting resin.

[0047] The outer surface of the rotor 6 is p...

Embodiment 2

[0061] Further illustrate in conjunction with embodiment 1, as Figure 1~11 As shown, the screw motor rotor 6 uses a tool on the machining center to machine the surface of the screw segment of the rotor 6 into obliquely intersecting kerfs 601, and a bump is formed between the kerf 601 and the kerf 601, forming a plurality of helical lines. The bulge, the bulge is only chamfered.

[0062] Place the rotor 6 for processing the diagonally intersecting knife grooves 601 on the first clamping head 4, the first clamping head 4 is lifted by the first air cylinder 3, and the motor 1004 is driven to drive the first clamping head 4 to slide to the dressing mold 7 between the upper template 702 and the lower template 703.

[0063] The first cylinder 3 is retracted so that the rotor 6 is transported to the inside of the tank body of the lower die plate 703 , and the second cylinder 8 is lifted up to close the upper die plate 702 and the lower die plate 703 .

[0064] The hot runner 701 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com