A coal flow detection method based on area lidar

A technology of laser radar and detection method, which is applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of complex construction and installation, large errors, and easy damage, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A further detailed description of the technical solutions of the present invention will be described in conjunction with specific embodiments and drawings.

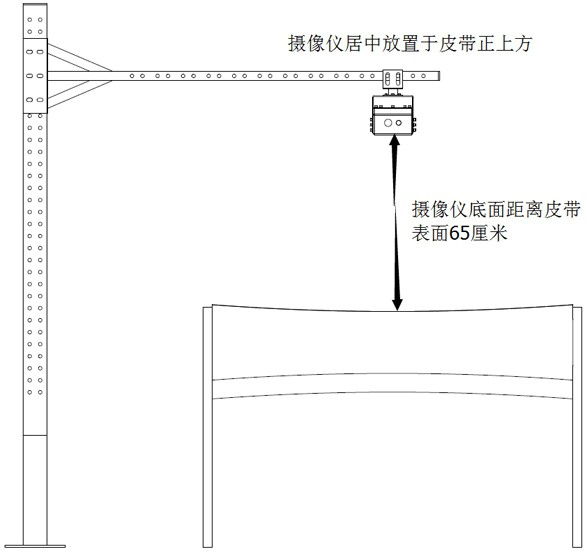

[0028] Append figure 1 The intelligent depth detector used in a coal flow detection method based on a surface laser radar is attached to the center position of the belt conveyor through the L-shelf.

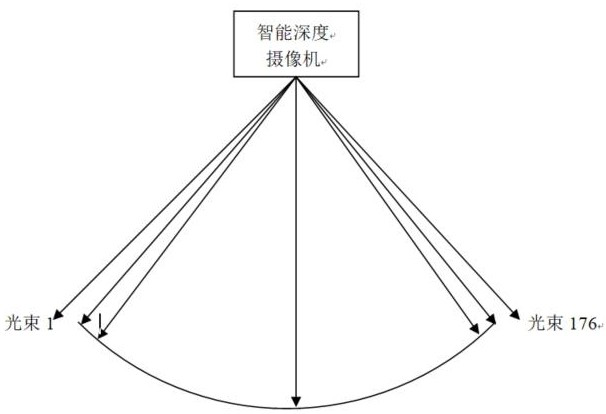

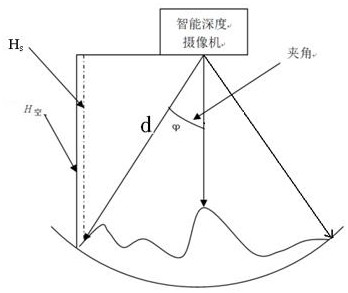

[0029] S1: figure 2 As shown: The laser radar column mirror emits 176 beam laser light at an angle of 0.5 degrees, and the 176 bundle laser light is shown in a fan-shaped distribution. The main controller of the laser radar is sequentially measured by a 176-bundled laser at 200 ms. Actual distance d;

[0030] S2: Judgment the belt conveyor belt width: compare the first bundle laser light and the second beam laser light, the first bundle light line and the 175 beam, the second beam laser light and the third beam light line are compared, the 175 beam light Compared to the 174th beam, it is contrast to the intermediate beam....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com