Coal blender

A coal machine and coal blending technology, which is applied to conveyors, mixers, conveyor objects, etc., can solve the problems of the loose molecular structure of coal, the impact on the health of workers, and the quality of coal blending machines. The effect of reducing air pollution and smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

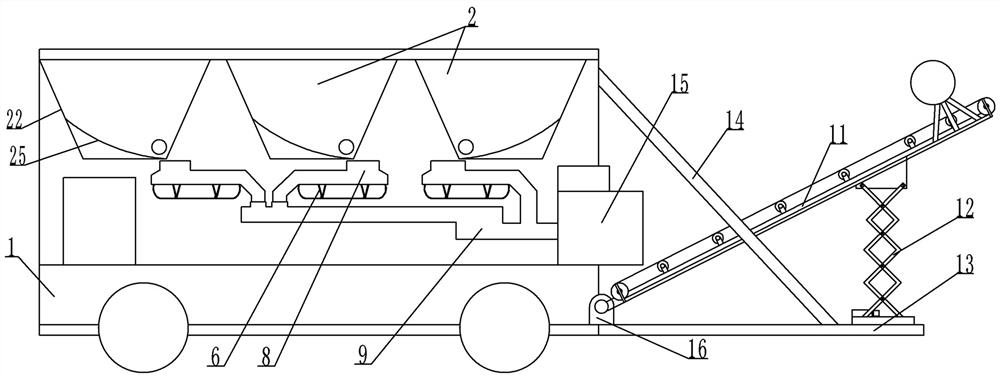

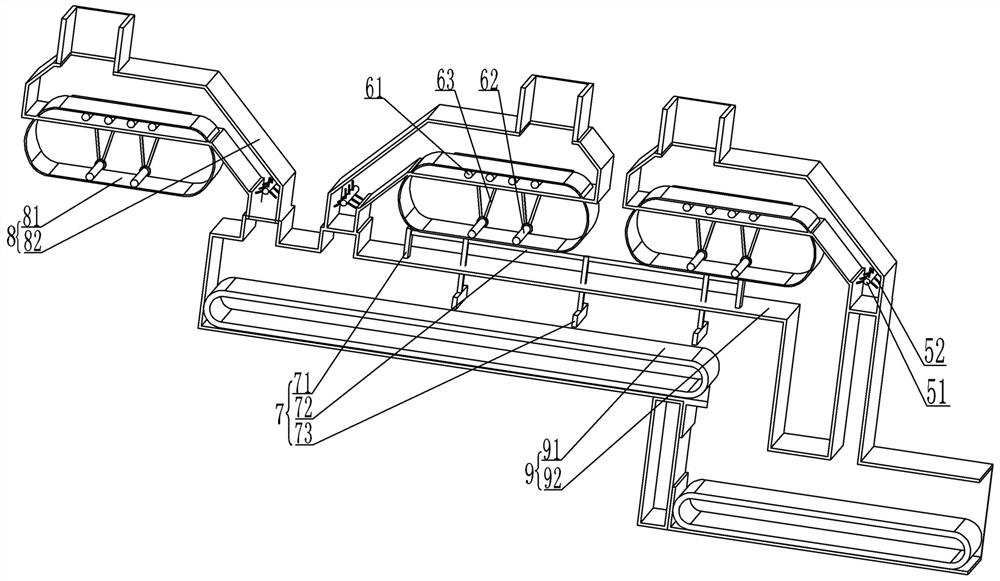

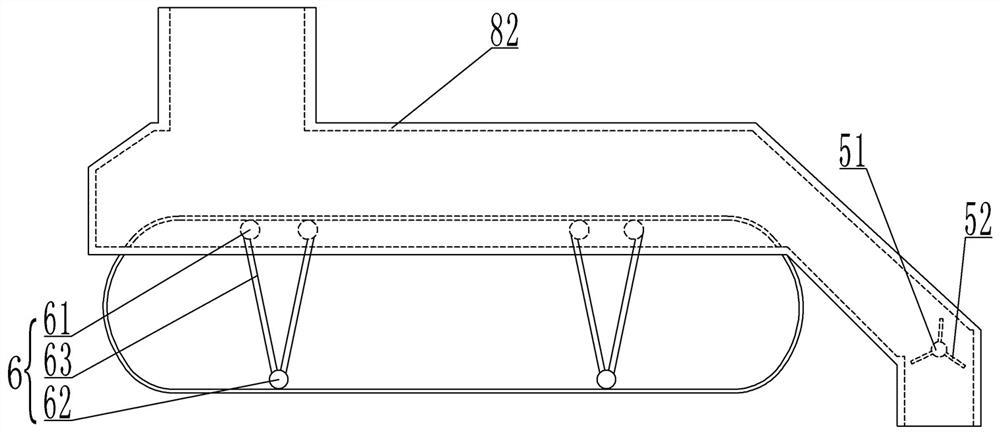

[0039] Example coal blender

[0040] This example Figure 1-Figure 4 As shown, a coal blender includes a car body 1 and three batching hoppers 2 fixed on the car body 1, wherein each batching hopper 2 is provided with a weighing mechanism 8 and a weighing mechanism 8 The material transport mechanism 9 that cooperates with each other, the car body 1 is fixedly provided with a control device, and the car body 1 is fixedly provided with a material bin 15 for mixing the coal materials on the three material transport mechanisms 9. The feed bin 15 is provided with a crushing device for crushing large coal materials, and the crushing device adopts the prior art. This embodiment is improved based on the Type 50 coal blender. The weighing mechanism 8 and the material transport mechanism 9 are both driven by the Type 50 coal blender structure, that is, the weighing belt 81 and the material conveyor belt 91 are both It is a trough conveyor belt, which can realize the most basic coal bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com