In-situ synthesized boron nitride nanosheet-nanotube composite material and preparation method thereof

A composite material, in-situ synthesis technology, applied in the fields of nitrogen compounds, chemical instruments and methods, nanotechnology, etc., to achieve the effects of simple and controllable preparation methods, good repeatability, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method for in-situ synthesis of boron nitride nanosheet-nanotube composite material, the specific steps are as follows:

[0025] (1) Preparation of "catalyst-anchored boron nitride nanosheets": Add 0.01mol boron nitride nanosheets, 0.05mol sodium citrate, and 0.25mol nickel chloride hexahydrate to 250ml of deionized water in sequence, stir, sonicate, Filtration and vacuum drying at 80° C. for 24 hours yielded “catalyst-anchored boron nitride nanosheets”.

[0026] (2) Preparation of boron nitride nanosheet-nanotube composite material: the "catalyst-anchored boron nitride nanosheet" obtained in step (1) is placed in a chemical vapor deposition system, using borazine as a precursor, Argon at a flow rate of 50ml / min was used as the carrier gas, heat-treated at 1000°C for 3h, and then naturally cooled to room temperature to obtain in situ synthesized boron nitride nanosheet-nanotube composites.

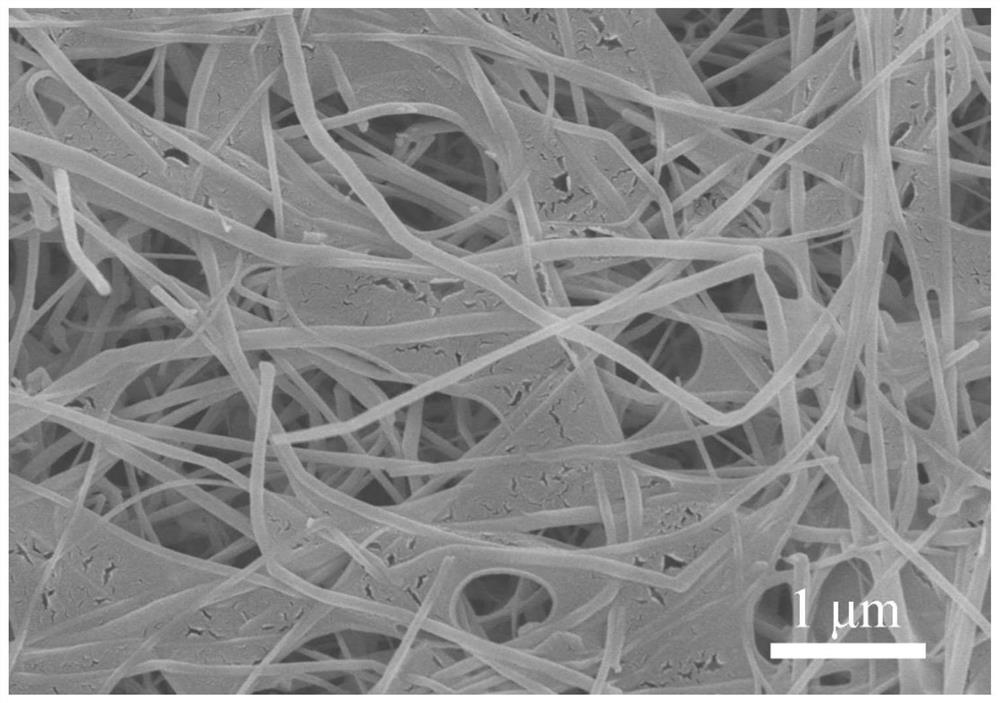

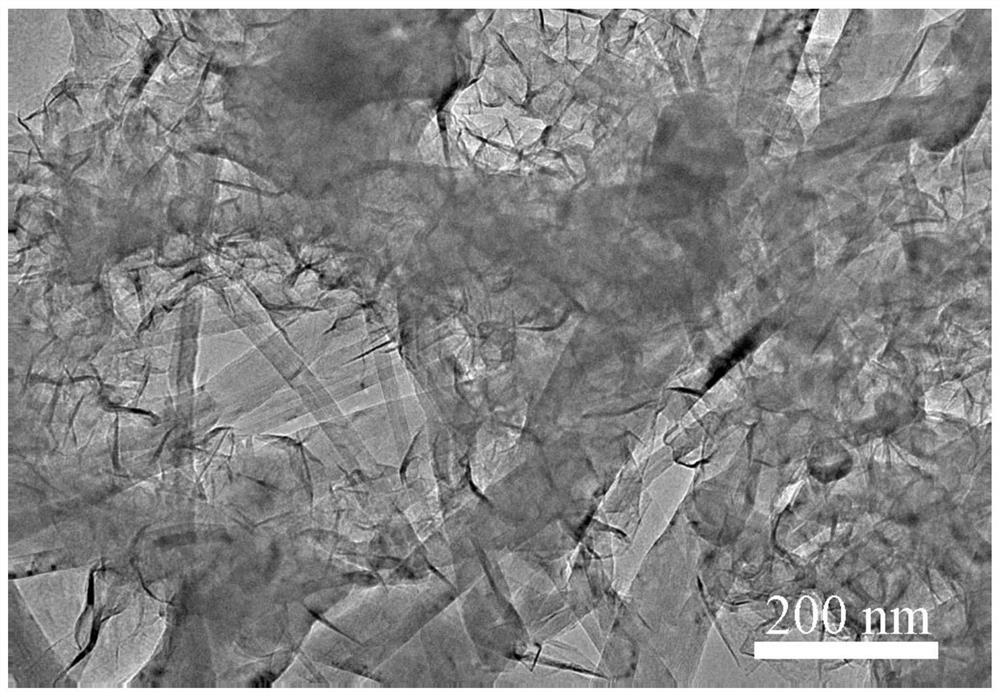

[0027] figure 1 It is the SEM picture of the product prepared i...

Embodiment 2

[0029] A preparation method for in-situ synthesis of boron nitride nanosheet-nanotube composite material, the specific steps are as follows:

[0030] (1) Preparation of "catalyst-anchored boron nitride nanosheets": Add 0.01mol boron nitride nanosheets, 0.25mol sodium tartrate, and 0.5mol nickel chloride hexahydrate to 250ml of deionized water in sequence, stir, sonicate, and filter , 120° C. vacuum drying for 6 hours to obtain “catalyst-anchored boron nitride nanosheets”.

[0031] (2) Preparation of boron nitride nanosheet-nanotube composite material: the "catalyst-anchored boron nitride nanosheet" obtained in step (1) is placed in a chemical vapor deposition system, using borazine as a precursor, Argon at a flow rate of 100ml / min was used as the carrier gas, heat-treated at 1200°C for 1 h, and then naturally cooled to room temperature to obtain in situ synthesized boron nitride nanosheet-nanotube composites.

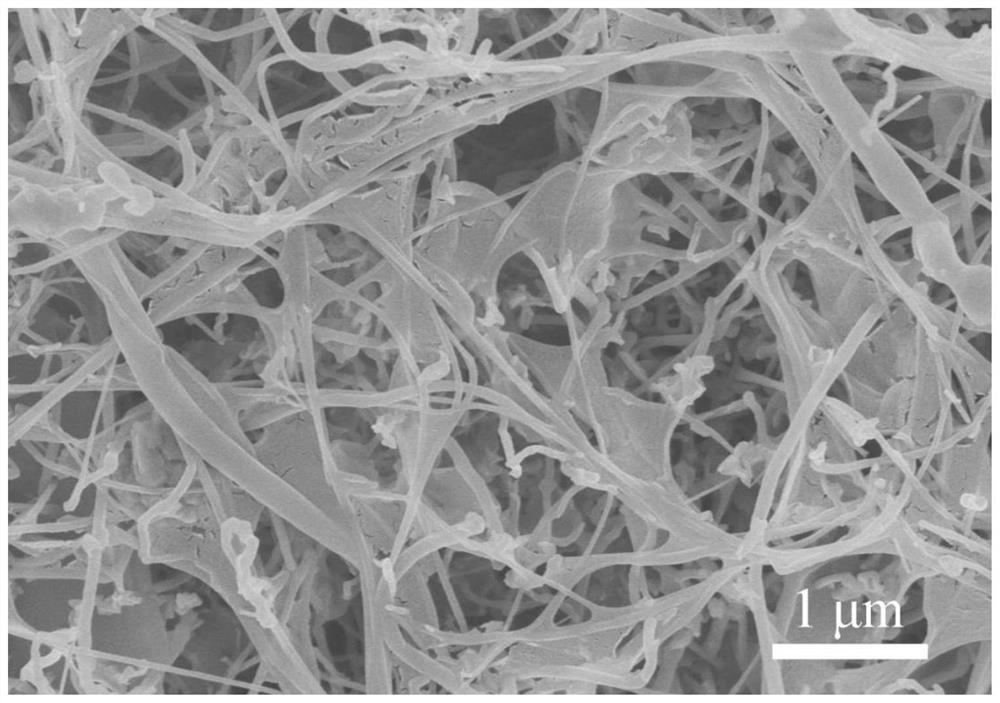

[0032] image 3 It is the SEM picture of the product prepared in...

Embodiment 3

[0034] A preparation method for in-situ synthesis of boron nitride nanosheet-nanotube composite material, the specific steps are as follows:

[0035] (1) Preparation of "catalyst-anchored boron nitride nanosheets": Add 0.01mol boron nitride nanosheets, 0.25mol sodium citrate, and 0.5mol nickel nitrate hexahydrate to 250ml deionized solution in sequence, stir, sonicate, and filter , 120° C. vacuum drying for 24 hours to obtain “catalyst-anchored boron nitride nanosheets”.

[0036] (2) Preparation of boron nitride nanosheet-nanotube composite material: the "catalyst-anchored boron nitride nanosheet" obtained in step (1) is placed in a chemical vapor deposition system, using borazine as a precursor, Argon at a flow rate of 100ml / min was used as the carrier gas, heat-treated at 1000°C for 1 h, and then naturally cooled to room temperature to obtain in situ synthesized boron nitride nanosheet-nanotube composites.

[0037] Using a method similar to Example 1 to characterize the produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap