Method for removing impurity iron in industrial silicon

A technology for industrial silicon and impurities, applied in chemical instruments and methods, improvement of process efficiency, silicon compounds, etc., can solve problems such as reducing Fe content, achieve low production costs, broad application prospects, and solve the effect of dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

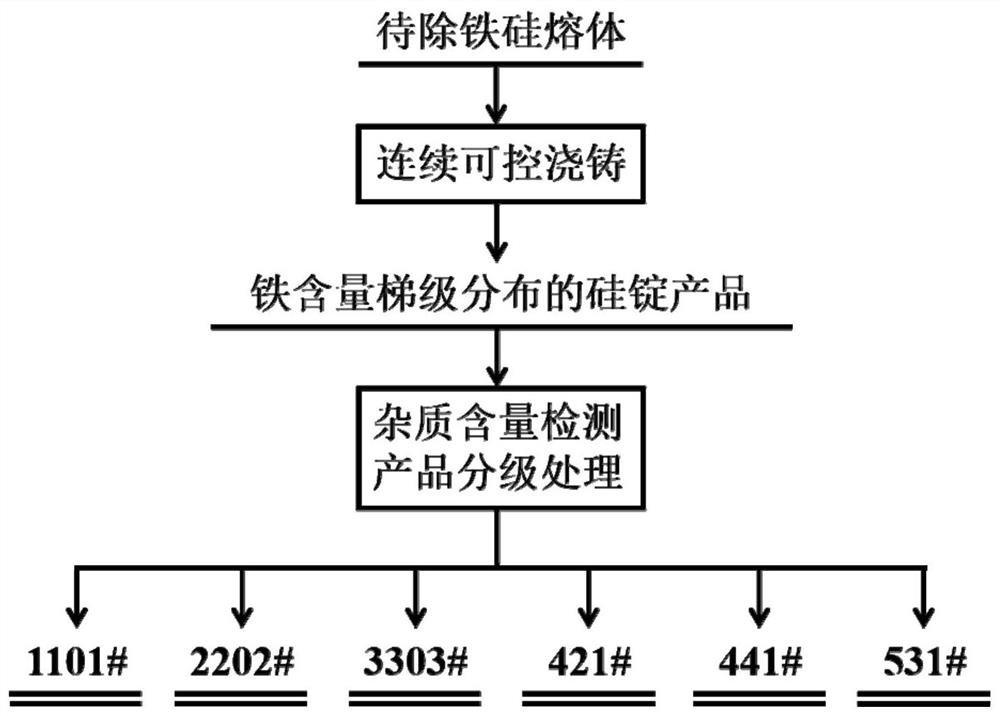

[0019] Embodiment 1: as figure 1 As shown, a method for removing impurity iron in industrial silicon, the specific steps are as follows:

[0020] (1) Add the silicon melt directly smelted from the submerged arc furnace into the directional solidification continuous casting device at a constant speed, and adjust the degree of supercooling and Directional solidification speed, the continuous ingot casting of industrial silicon can realize continuous feeding and continuous ingot output, and promote the continuous segregation and enrichment of Fe impurities with a segregation coefficient much smaller than 1 in the industrial silicon melt to the uncrystallization of the directional solidification continuous casting device In the melt, a silicon ingot product with a graded distribution of iron content is obtained; the temperature of the silicon melt to be iron-removed is 1750°C, the flow rate of the silicon melt is 0.1kg / s, and the directional solidification speed is 0.1cm / s;

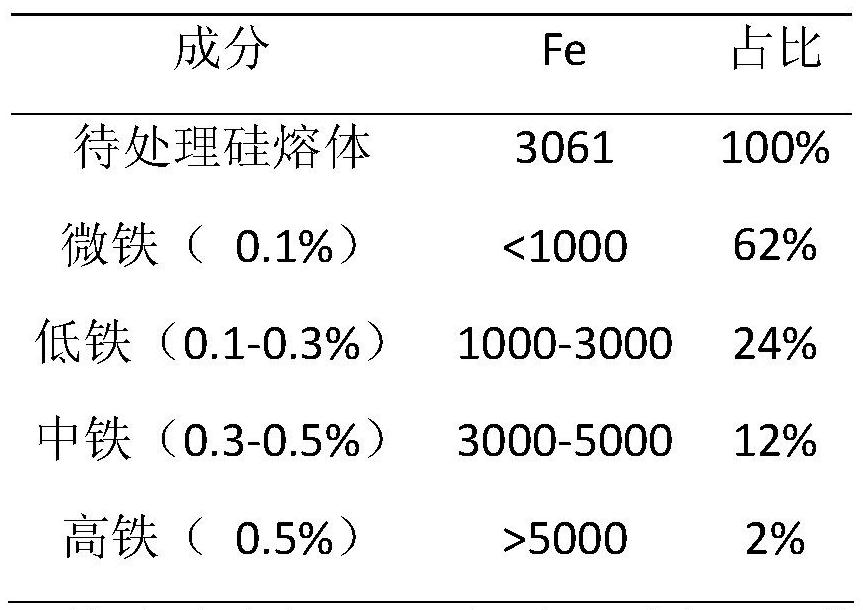

[00...

Embodiment 2

[0026] Embodiment 2: as figure 1 Shown, a kind of removal method of impurity iron in industrial silicon, concrete steps are as follows:

[0027] (1) Add the silicon melt refined outside the furnace into the directional solidification continuous casting device continuously and at a constant speed, and adjust the supercooling degree and directional solidification of the directional solidification continuous casting device according to the size of the directional solidification continuous casting device and the real-time temperature of the melt The continuous ingot casting of industrial silicon realizes continuous feeding and continuous ingot output, which promotes the continuous segregation and enrichment of Fe impurities with a segregation coefficient much smaller than 1 in the industrial silicon melt to the uncrystallized melt of the directional solidification continuous casting device. In the body, a silicon ingot product with a graded distribution of iron content is obtained...

Embodiment 3

[0033] Embodiment 3: as figure 1 Shown, a kind of removal method of impurity iron in industrial silicon, concrete steps are as follows:

[0034](1) The silicon melt after melting the silicon-containing waste is continuously added to the directional solidification continuous casting device at a constant speed, and the supercooling degree and orientation of the directional solidification continuous casting device are adjusted according to the size of the directional solidification continuous casting device and the real-time temperature of the melt Solidification speed, the continuous ingot casting of industrial silicon realizes continuous feeding and continuous ingot output, and promotes the continuous segregation and enrichment of Fe impurities with a segregation coefficient much smaller than 1 in the industrial silicon melt to the uncrystallized solidification of the directional solidification continuous casting device. In the melt, a silicon ingot product with a graded distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com