High-speed electromagnetic pulse gas valve device

An electromagnetic pulse and air valve technology, which is applied in the direction of valve device, valve operation/release device, valve lift, etc., can solve the problems of large mass of moving iron core, slow response time of moving iron core movement, and slow action of electromagnetic valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

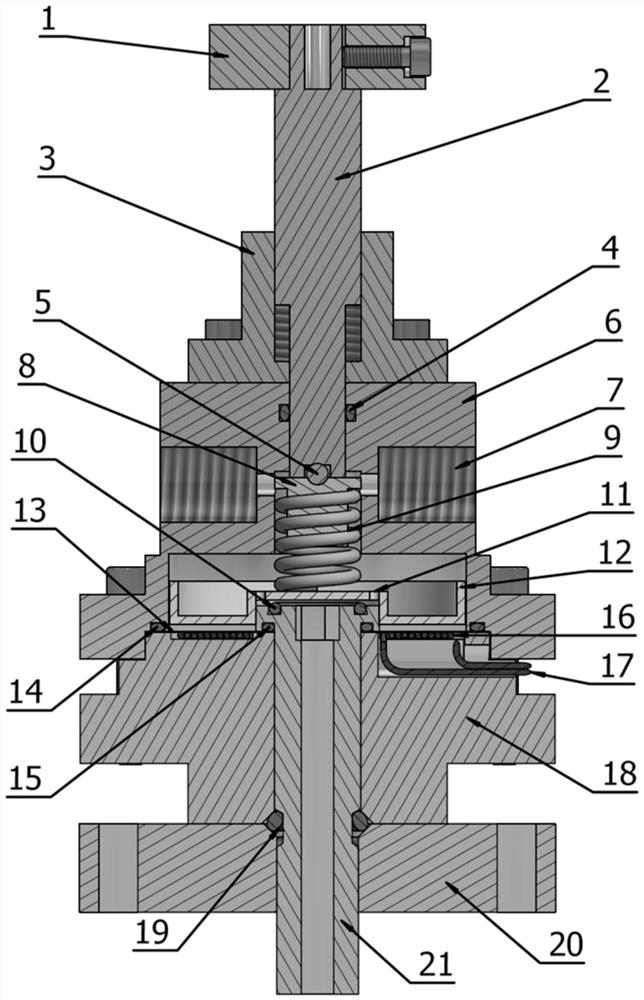

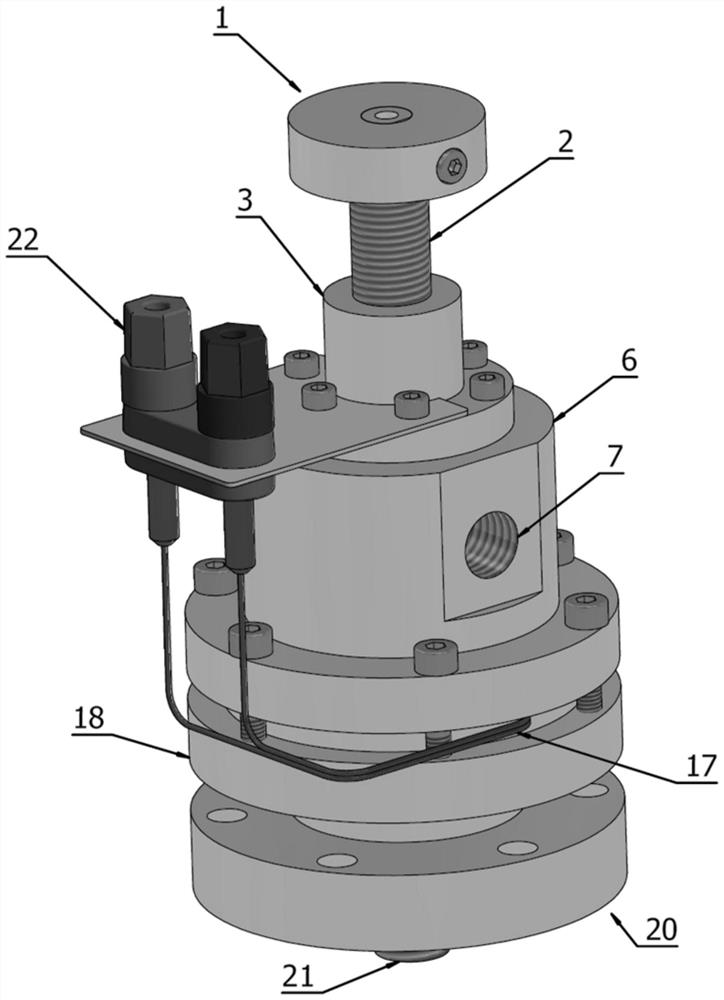

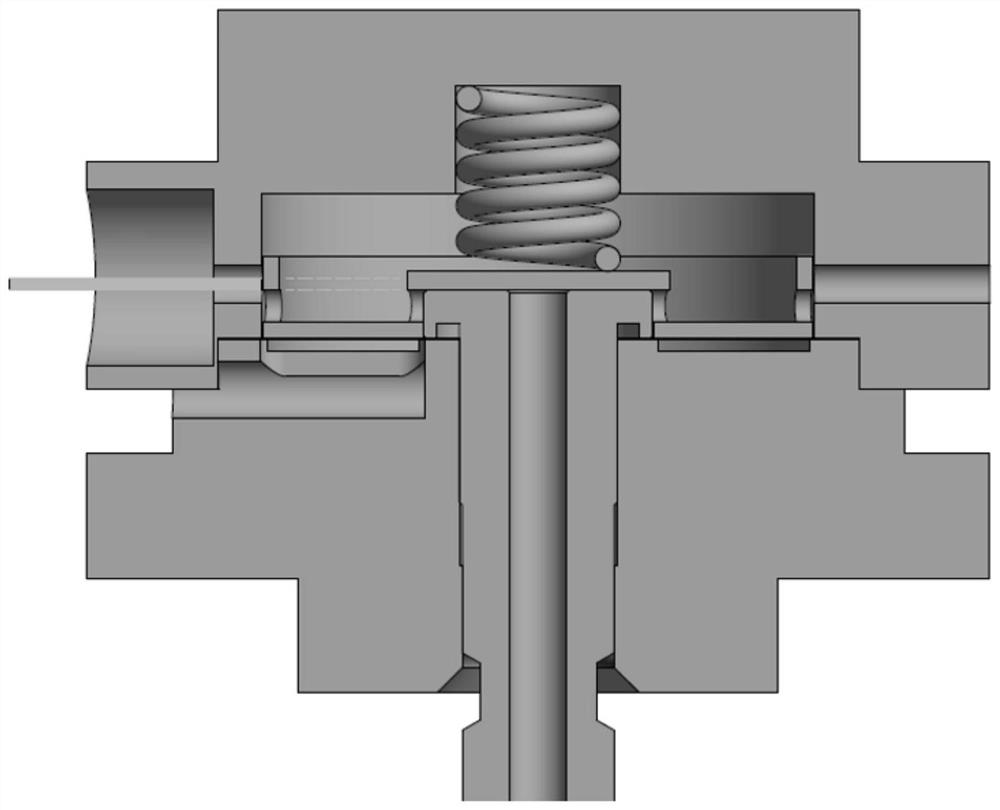

[0021] A high-speed electromagnetic pulse gas valve device of the present invention has a cavity between the valve body 18 and the gas chamber casing 6 as the gas chamber, and the air inlet 7 is used to feed the working gas into the cavity, and there is a movable valve in the cavity. Disc-shaped piston 12, the material of piston 12 is aluminum to reduce its weight. Under the action of the spring 9 , the piston 12 presses on the second O-ring 10 at the top of the lower valve stem 21 , thereby disconnecting the air path between the air chamber and the lower valve stem 21 . The degree of tightness of the spring 9 is determined by the up and down position of the spring holder 8. By rotating the handle 1, the upper valve stem 2 is driven to be screwed in and out along the threaded channel of the upper casing 3, so that the upper and lower positions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com