MBR (Membrane Bioreactor) integral sewage treatment equipment with automatic sludge discharge

A sewage treatment equipment and automatic drainage technology, applied in water/sludge/sewage treatment, biological water/sewage treatment, water treatment parameter control, etc. Maintain stability and control flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

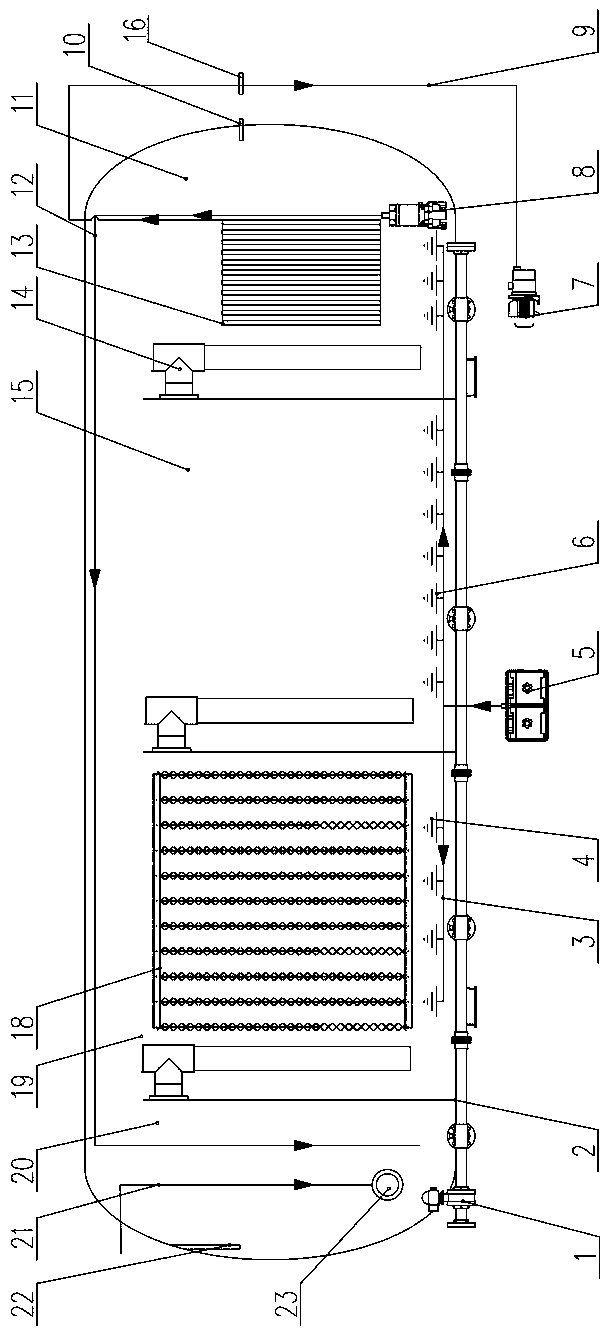

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

[0019] Such as figure 1 As shown, the MBR integrated sewage treatment equipment with automatic sludge discharge includes pretreatment area 20, anoxic area 19, aerobic area 15, membrane area 11, sludge discharge pipe 2, and PLC control system (not shown in the figure).

[0020] A water distributor 23 is installed at the bottom of the pretreatment area 20. Sewage enters the pretreatment area 20 through the water inlet pipe 21. The water distributor 23 homogeneously mixes the sewage and stirs the bottom sludge to avoid sludge deposition at the bottom of the equipment.

[0021] The pretreatment area 20 is also provided with a return line 12, which enters the pretreatment area 20 from the membrane area 11 through the return pump 8 through the return line 12, and the sewage feed water is mixed with the reflux liquid returned from the membrane area through the return line 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com