Composite high-efficiency circulating water treatment device

A treatment device and circulating water technology, applied in multi-stage water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of single function and high cost of waste water treatment, and achieve the reduction of waste water treatment cost and good recycling The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

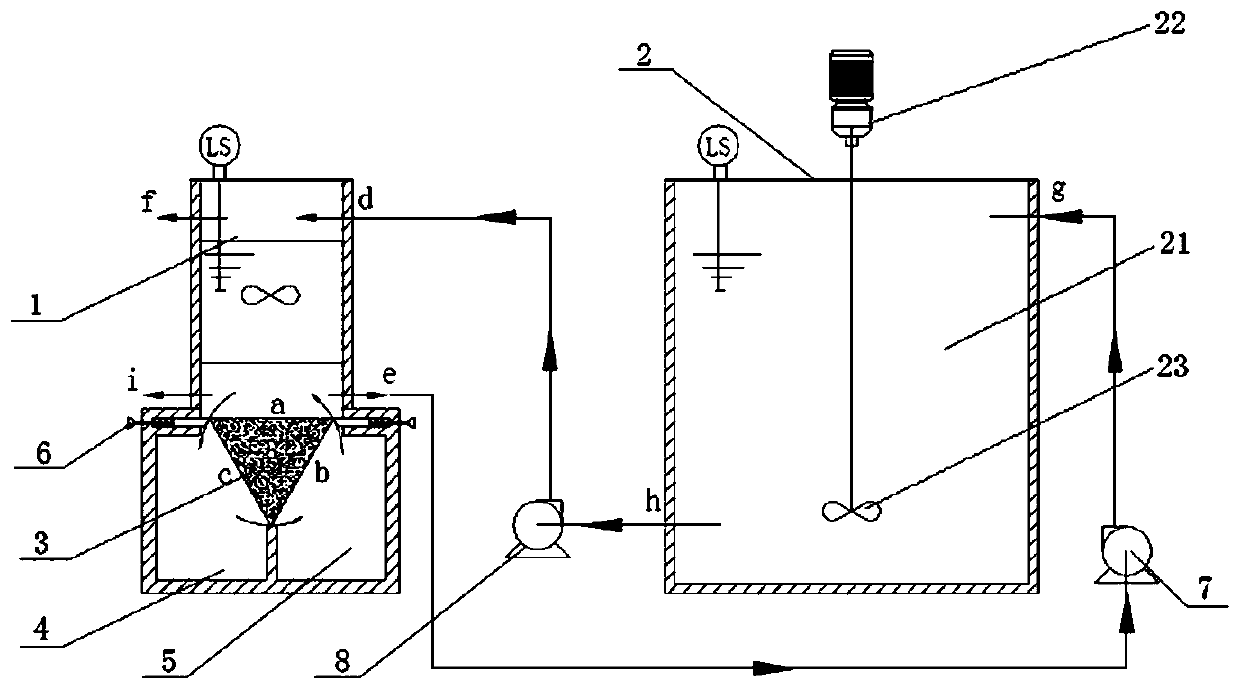

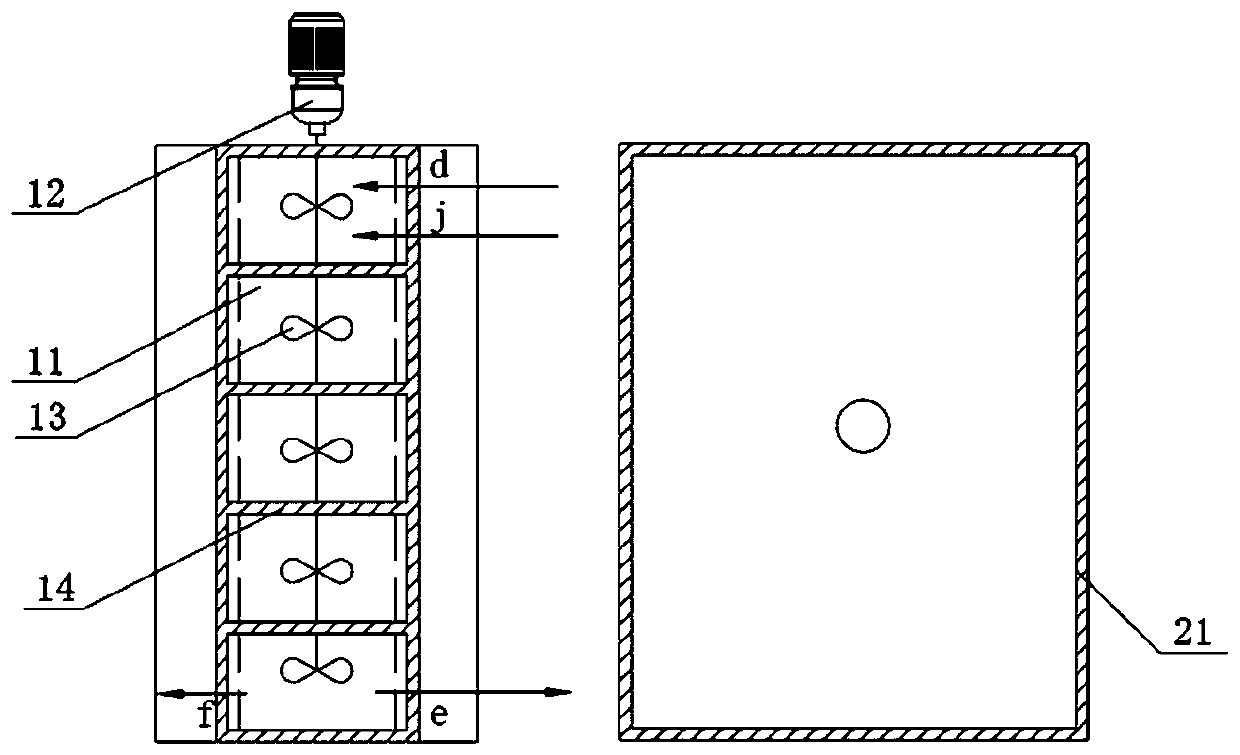

[0019] Such as figure 1 , 2 As shown, a composite high-efficiency circulating water treatment device includes a buffer 1, a reactor 2, a magnetic separator 3, a magnetic adsorption material regeneration chamber 4 and a magnetic adsorption material replacement chamber 5, and the magnetic separator 3 includes three working The three working surfaces are respectively located in the buffer 1, the magnetic adsorption material regeneration chamber 5 and the magnetic adsorption material replacement chamber 4. The magnetic separator 3 is driven by the rotating mechanism so that the positions of the three working surfaces are rotated. A sealing mechanism 6 is also provided between the buffer 1 and the magnetic adsorption material replacement chamber 5, between the buffer 1 and the magnetic adsorption material regeneration chamber 4; between the buffer 1 and the reactor 2 through a water pipeline and a water pump form a loop;

[0020] In the present invention, the specific connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com