Preparation method for graphite phase carbon nitride/high bismuth oxyiodide heterojunction with up-conversion characteristics and product thereof, and application of product

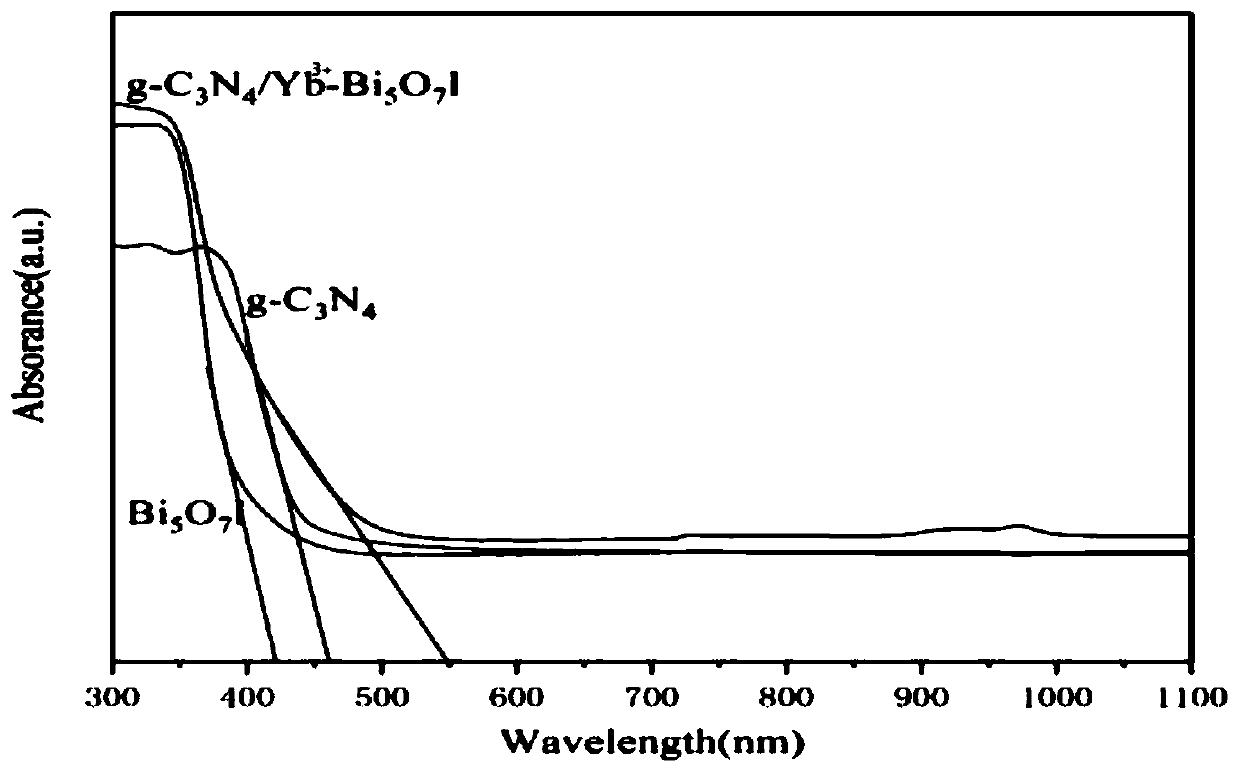

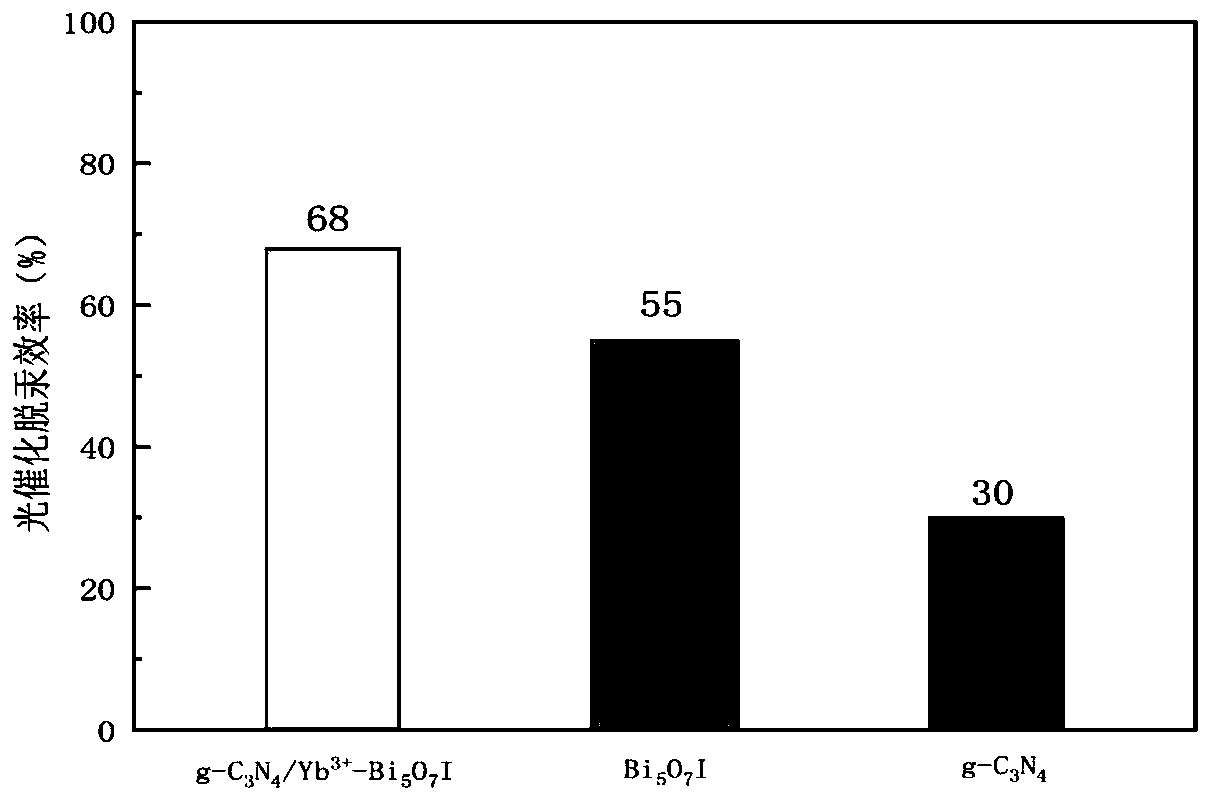

A technology of graphite phase carbon nitride and conversion characteristics, applied in the field of photocatalytic materials, can solve the problem of low recombination efficiency of photogenerated carriers, achieve excellent electron-hole separation ability, large spectral response range, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

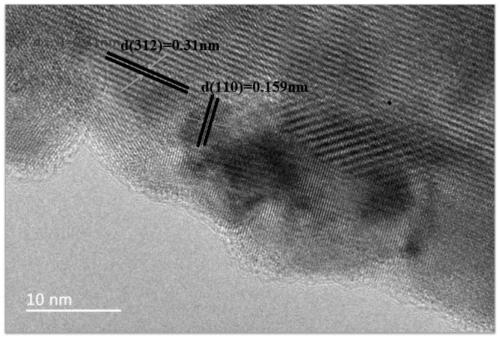

[0030] This embodiment provides a method for preparing a graphitic phase carbon nitride / bismuth periodinite heterojunction with up-conversion properties:

[0031] (1) Calcining urea at 550°C for 4h to obtain powdered g-C 3 N 4 , the calcination heating rate is 5°C / min.

[0032] (2) Weigh 3mmol of Bi(NO 3 ) 3 ·5H 2 O was dispersed into 10ml of ethylene glycol, and ultrasonicated to a uniform solution, which was recorded as solution A, wherein the ultrasonic time was 10min, and the ultrasonic frequency was 40KHz.

[0033] (3) Weigh 0.13mmol of Yb(NO 3 ) 3 Dispersed into 5ml of ethylene glycol, ultrasonicated to a uniform solution, which was recorded as solution B, wherein the ultrasonic time was 10min, and the ultrasonic frequency was 40KHz.

[0034] (4) Weigh 2mmol of g-C prepared in (1) 3 N 4 Dispersed into 10ml of ethylene glycol, ultrasonicated to a uniform solution, which was recorded as solution C, wherein the ultrasonic time was 10min, and the ultrasonic frequenc...

Embodiment 2

[0042] This embodiment provides a method for preparing a graphitic phase carbon nitride / bismuth periodinite heterojunction with up-conversion properties:

[0043] (1) Calcining urea at 550°C for 4h to obtain powdered g-C 3 N 4 , the calcination heating rate is 5°C / min.

[0044] (2) Weigh 3mmol of Bi(NO 3 ) 3 ·5H 2 O was dispersed into 10ml of ethylene glycol, and ultrasonicated to a uniform solution, which was recorded as solution A, wherein the ultrasonic time was 5min, and the ultrasonic frequency was 35KHz.

[0045] (3) Weigh 0.13mmol of Yb(NO 3 ) 3 Dispersed into 5ml of ethylene glycol, ultrasonicated to a uniform solution, which was recorded as solution B, wherein the ultrasonic time was 5min, and the ultrasonic frequency was 35KHz.

[0046] (4) Weigh 2mmol of g-C prepared in (1) 3 N 4 Dispersed into 10ml of ethylene glycol, ultrasonicated to a uniform solution, which was recorded as solution C, wherein the ultrasonic time was 5min, and the ultrasonic frequency w...

Embodiment 3

[0052] This embodiment provides a method for preparing a graphitic phase carbon nitride / bismuth periodinite heterojunction with up-conversion properties:

[0053] (1) Calcining urea at 550°C for 4h to obtain powdered g-C 3 N 4 , the calcination heating rate is 5°C / min.

[0054] (2) Weigh 3mmol of Bi(NO 3 ) 3 ·5H 2 O was dispersed into 10ml of ethylene glycol, and ultrasonicated to a uniform solution, which was recorded as solution A, wherein the ultrasonic time was 10min, and the ultrasonic frequency was 35KHz.

[0055] (3) Weigh 0.13mmol of Yb(NO 3 ) 3 Dispersed into 5ml of ethylene glycol, ultrasonicated to a uniform solution, which was recorded as B solution, wherein the ultrasonic time was 10min, and the ultrasonic frequency was 35KHz.

[0056] (4) Weigh 2mmol of g-C prepared in (1) 3 N 4 Dispersed into 10ml of ethylene glycol, ultrasonicated to a uniform solution, which was recorded as solution C, wherein the ultrasonic time was 10min, and the ultrasonic frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com