Sealant and preparation method thereof

A sealant and sealing material technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of slow surface drying time, long deep curing time, affecting the production process of precision electronic products, etc. Cured surface dry quickly, excellent bonding strength and physical and mechanical properties, the effect of excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

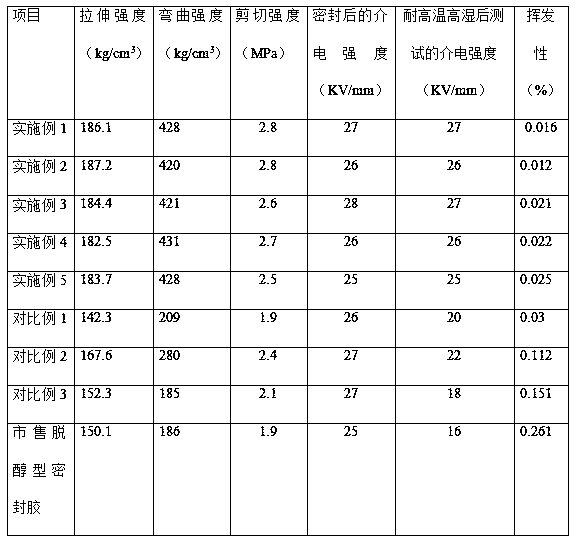

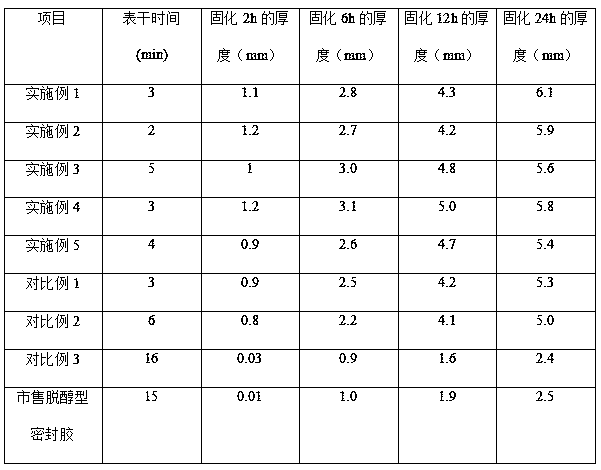

Examples

Embodiment 1

[0030] The preparation method of sealant specifically comprises the following steps:

[0031] Step (1): Put 60g of nano-CaCO3, 1g of hexamethylsilazane and 100g of α, ω dihydroxy polydimethylsiloxane into a kneader and mix them. After kneading evenly, heat up to 100°C and evacuate to -0.08MPa Degassing for 90 minutes to obtain sealing material base 1;

[0032] Step (2): Put the base material 1 obtained in step (1) into a power mixer, then mix 10 g of trimethylisopropenyloxysilane with it, and stir evenly at room temperature for 20 minutes to obtain the sealing material base 2 ;

[0033] Step (3): Put 3g of N-(2-aminoethyl)-3-aminopropyltrimethoxysilane into the obtained sealing material base material 2, and stir evenly at room temperature for 20 minutes to obtain the sealing material base material 3;

[0034] Step (4): Put 3 g of tackifying resin into the sealing material base 3 obtained in step (3), and stir evenly at room temperature for 20 minutes to obtain sealing materi...

Embodiment 2

[0037] The preparation method of sealant specifically comprises the following steps:

[0038] Step (1): Put 60g SiO2, 2g lactone and 100gα,ωdihydroxy polydimethylsiloxane into a kneader and mix them. After kneading evenly, heat up to 120°C and vacuumize to -0.06MPa for 120min to obtain a sealed seal. material base1;

[0039] Step (2): Put base material 1 obtained in step (1) into a dynamic mixer, then mix 12 g of phenyltriisopropenyloxysilane with it, and stir evenly at room temperature for 30 minutes to obtain sealing material base 2;

[0040] Step (3): Put 3 g of γ-aminopropyltrimethoxysilane into the obtained sealing material base 2, and stir evenly at room temperature for 30 minutes to obtain the sealing material base 3;

[0041] Step (4): Mix the sealing material base 3 obtained in step (3) with 5 g of tackifying resin, and stir evenly at room temperature for 30 minutes to obtain the sealing material base 4;

[0042] Step (5): Mix the sealing material base 4 obtained in...

Embodiment 3

[0044] The preparation method of sealant specifically comprises the following steps:

[0045] Step (1): Put 70g of kaolin, 2g of tris (6-isocyanatohexyl) isocyanate and 90g of α, ω dihydroxy polydimethylsiloxane into the kneader and mix them. After kneading evenly, heat up to 110°C and evacuate to -0.085MPa defoaming for 120min to obtain sealing material base 1;

[0046] Step (2): put the base material 1 obtained in step (1) into a dynamic mixer, then mix 12 g of vinyltriisopropenyloxysilane with it, and stir evenly at room temperature for 30 minutes to obtain the sealing material base 2;

[0047] Step (3): Put 3 g of γ-aminopropyltriethoxysilane into the obtained sealing material base 2, and stir evenly at room temperature for 30 minutes to obtain the sealing material base 3;

[0048] Step (4): Mix the sealing material base 3 obtained in step (3) with 3 g of tackifying resin, and stir evenly at room temperature for 30 minutes to obtain sealing material base 4;

[0049] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com