Grain cooling machine

A technology for coolers and grains, applied in refrigerators, seeds stored by freezing/cooling, compressors, etc., can solve the problems of destroying the dynamic balance of fan blades, affecting the service life of fans, and the inapplicability of coolers, etc., to achieve reduction Effects of heat exchange, increasing water spray volume, and reducing water spray volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

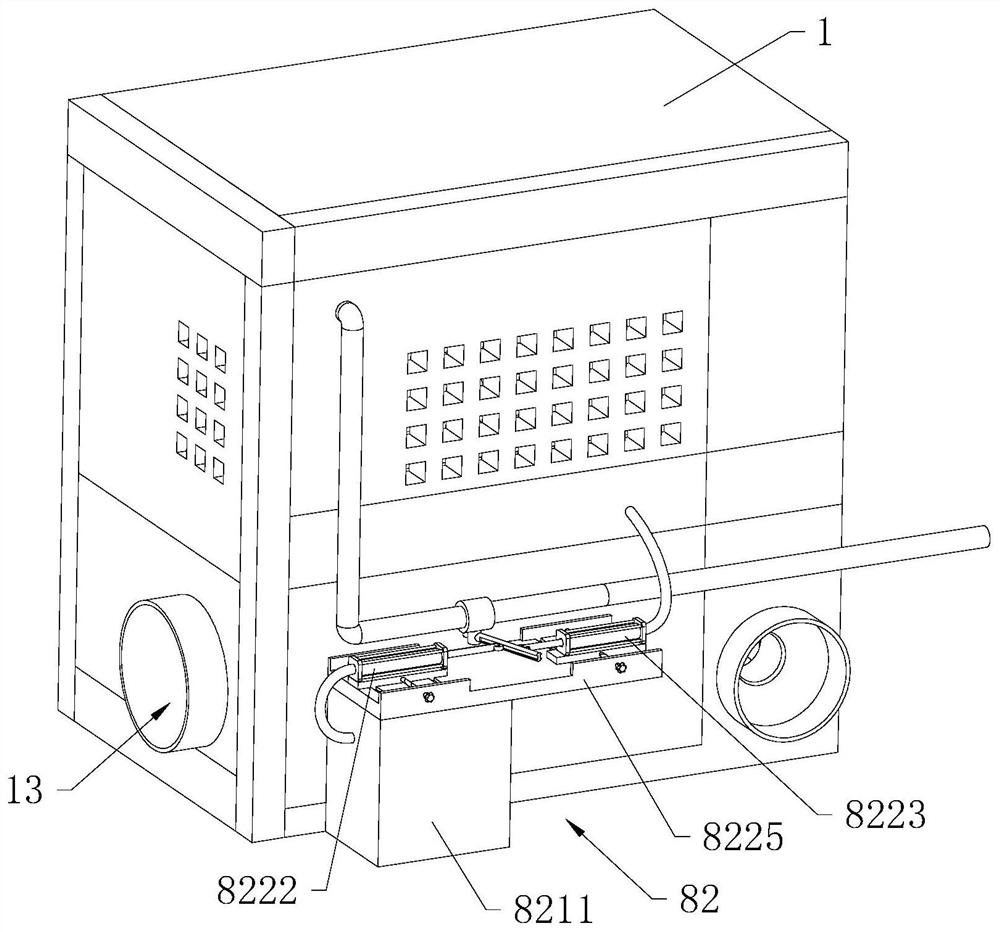

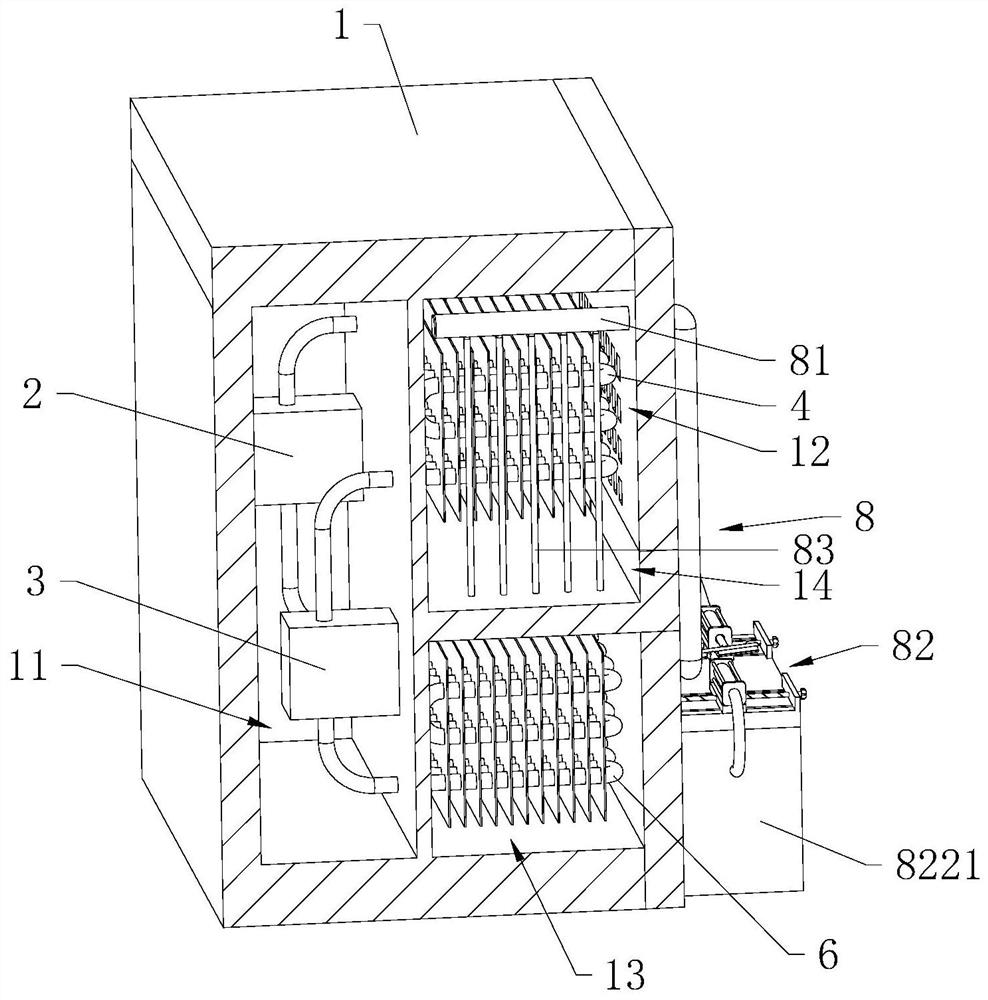

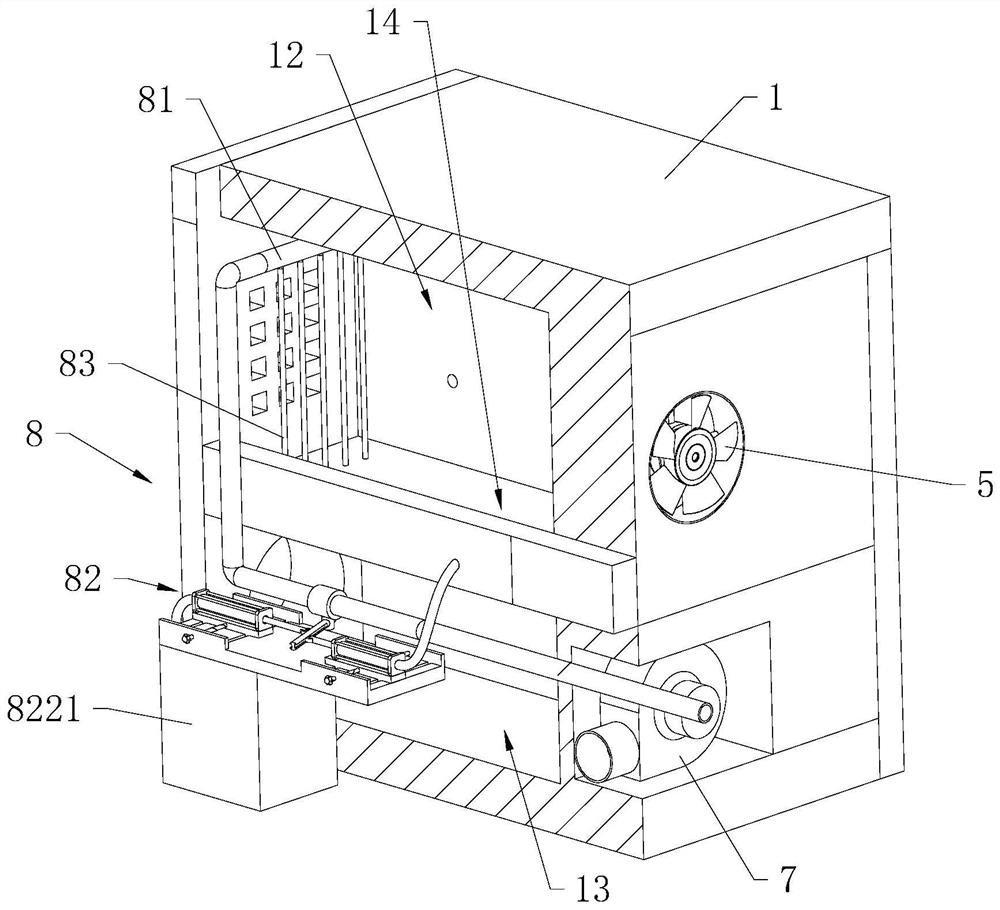

[0051] Attached to the following Figure 1-6 This application will be described in further detail.

[0052] The embodiment of the present application discloses a grain cooler. refer to figure 1 , the grain cooler includes body 1, refer to figure 2 There is an installation cavity 11 in the body 1, a compressor 2 and an expansion valve 3 are arranged in the installation cavity 11, and a hot air flow channel 12 and a cold air flow channel 13 are arranged in the body 1 and located on the side of the installation cavity 11 from top to bottom , refer to figure 2 , 3 , the hot air flow channel 12 is provided with a condenser 4 and a hot fan 5, and the cold air flow channel 13 is provided with an evaporator 6 and a cooling fan 7.

[0053] The medium circulates among the compressor 2, the condenser 4, the expansion valve 3, and the evaporator 6. The air cooler 7 makes the air flow in the cold air flow channel 13 and sends the cold air into the warehouse; The air flows in the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com