Double-cone rotary vacuum drying device and feeding method for copper powder drying

A vacuum drying device and double cone technology, applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve problems such as leakage of materials and impact on working environment, ensure air quality, avoid copper powder loss, The effect of avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

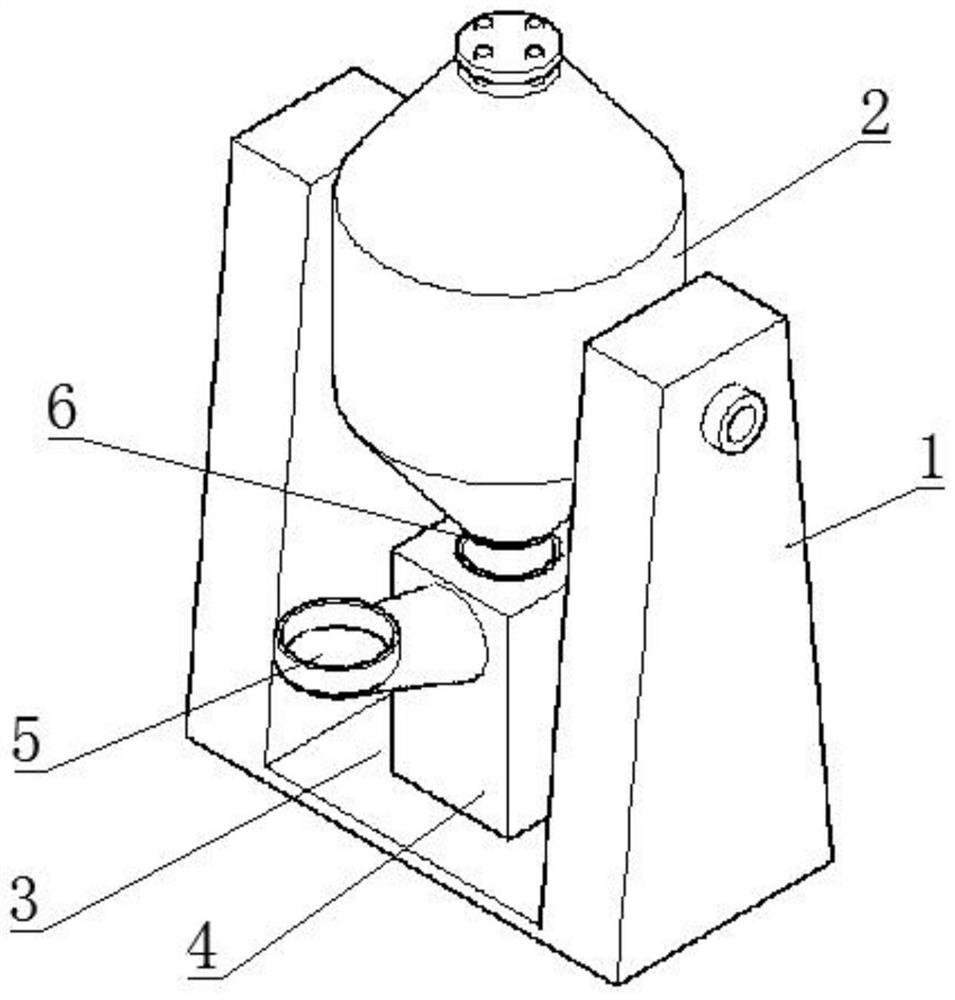

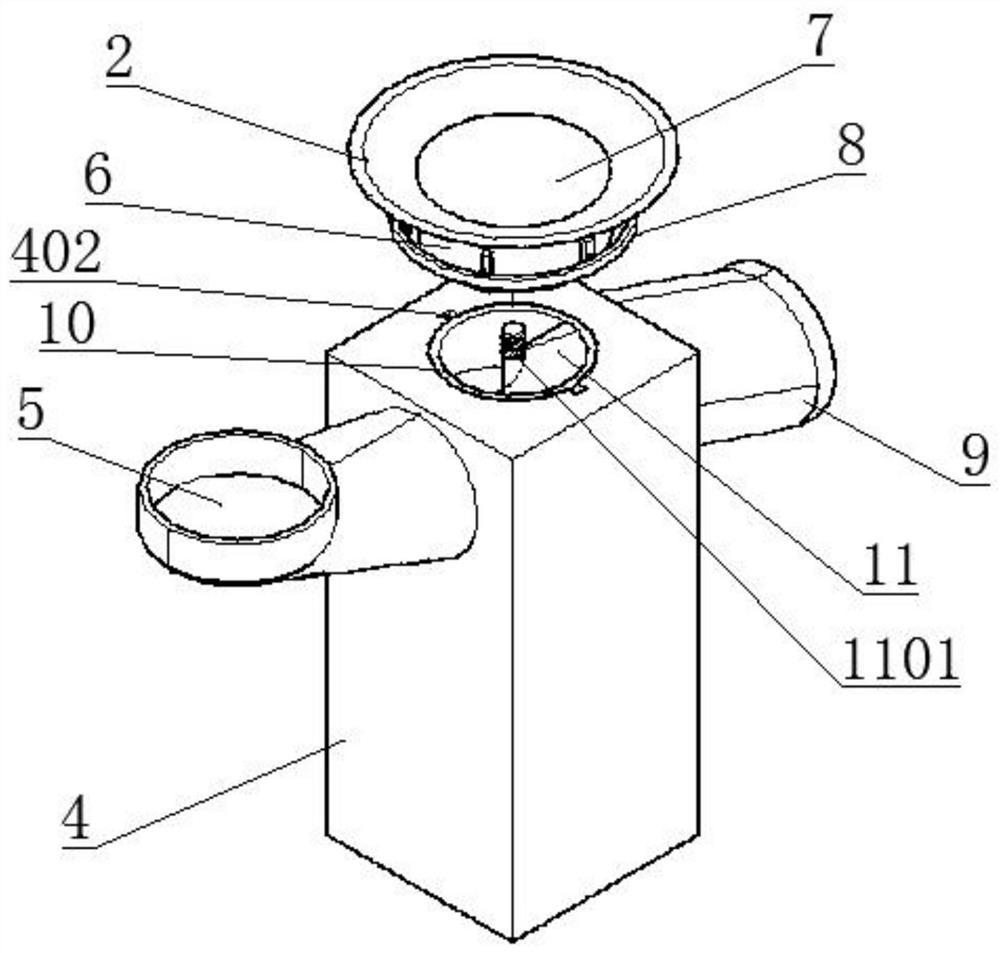

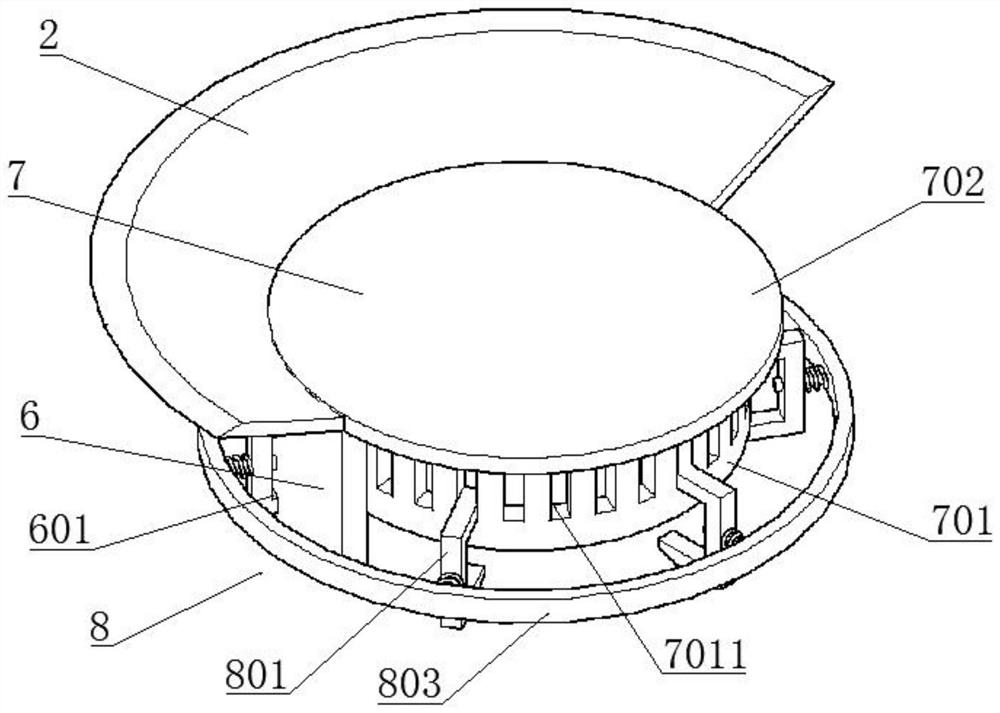

[0039] Such as Figure 1-3As shown, a double-cone rotary vacuum drying device for copper powder drying includes a frame 1, a drying cylinder 2 connected to it in rotation is arranged on the frame 1, a port pipe 6 is provided at one end of the drying cylinder 2, and a port pipe 6 is arranged on the port pipe. 6 places are provided with a sealing disc 7 coaxially sliding relative to the port pipe 6, and a feeding mechanism 3 is arranged on the frame 1. The feeding mechanism 3 includes a feeding box 4 fixed at the bottom of the frame 1, and the feeding box 4 There is an inserting sleeve 10 that slides axially with the material delivery box 4 inside. The inserting sleeve 10 is plugged with the port pipe 6. The inner axis of the inserting sleeve 10 is fixedly connected with a feeding shaft 11. The top end of the feeding shaft 11 is connected to the bottom of the sealing disc 7. The threaded sleeve 705 that is fixedly connected to the end radially is connected, and the side of the c...

Embodiment 2

[0042] Such as Figure 1-5 As shown, a double-cone rotary vacuum drying device for copper powder drying includes a frame 1, a drying cylinder 2 connected to it in rotation is arranged on the frame 1, a port pipe 6 is provided at one end of the drying cylinder 2, and a port pipe 6 is arranged on the port pipe. 6 places are provided with a sealing disc 7 coaxially sliding relative to the port pipe 6, and a feeding mechanism 3 is arranged on the frame 1. The feeding mechanism 3 includes a feeding box 4 fixed at the bottom of the frame 1, and the feeding box 4 There is an inserting sleeve 10 that slides axially with the material delivery box 4 inside. The inserting sleeve 10 is plugged with the port pipe 6. The inner axis of the inserting sleeve 10 is fixedly connected with a feeding shaft 11. The top end of the feeding shaft 11 is connected to the bottom of the sealing disc 7. The threaded sleeve 705 that is fixedly connected to the end radially is connected, and the side of the ...

Embodiment 3

[0045] Such as Figure 1-8 As shown, a double-cone rotary vacuum drying device for copper powder drying includes a frame 1, a drying cylinder 2 connected to it in rotation is arranged on the frame 1, a port pipe 6 is provided at one end of the drying cylinder 2, and a port pipe 6 is arranged on the port pipe. 6 places are provided with a sealing disc 7 coaxially sliding relative to the port pipe 6, and a feeding mechanism 3 is arranged on the frame 1. The feeding mechanism 3 includes a feeding box 4 fixed at the bottom of the frame 1, and the feeding box 4 There is an inserting sleeve 10 that slides axially with the material delivery box 4 inside. The inserting sleeve 10 is plugged with the port pipe 6. The inner axis of the inserting sleeve 10 is fixedly connected with a feeding shaft 11. The top end of the feeding shaft 11 is connected to the bottom of the sealing disc 7. The threaded sleeve 705 that is fixedly connected to the end radially is connected, and the side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com