Method for checking oil outlet speed of oil-retaining bearing

A kind of bearing and speed technology, which is used in mechanical bearing testing, by removing certain components, such as weighing and measuring devices, can solve the problem that there is no standard inspection method for oil output speed, so as to avoid the difference in volume and easy to operate. , the effect of high inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

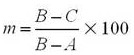

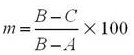

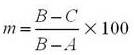

[0038] The φ2.3*φ9*3mm bearing used in the 385 type DC motor was impregnated with the imported oil sample of SHC626, and the noise decreased significantly after starting for 3~5s, and the impregnated self-produced CX2 oil sample with known formula was started for 10~15s After that, the noise decreased obviously, and the noise reduction speed was not as good as that of SHC626. During the test, it can be clearly seen that the bearing oil impregnated with SHC626 comes out faster. Utilizing the present invention, the temperature and baking time of the electric blast constant temperature drying oven are set at 150°C and 24h, and each oil sample uses 10 bearings to measure the data of SHC626, A=11.0166g, B=11.4552g, C =11.2878g, the calculated m=38.17%, the measured data of CX2, A=11.4644g, B=10.9784g, C=11.4058g, calculated m=12.06%, the result shows that the oil yield of CX2 is obviously lower than that of SHC626 , after adjusting the formula of CX2, CX2 measured the data again,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com