Frequency characteristic measurement device, controller and frequency characteristic measurement method

A technology of frequency characteristics and measuring devices, which is applied in the direction of frequency measuring devices, measuring devices, program control, etc., can solve the problems of longer measuring time, achieve high measuring accuracy and shorten the measuring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

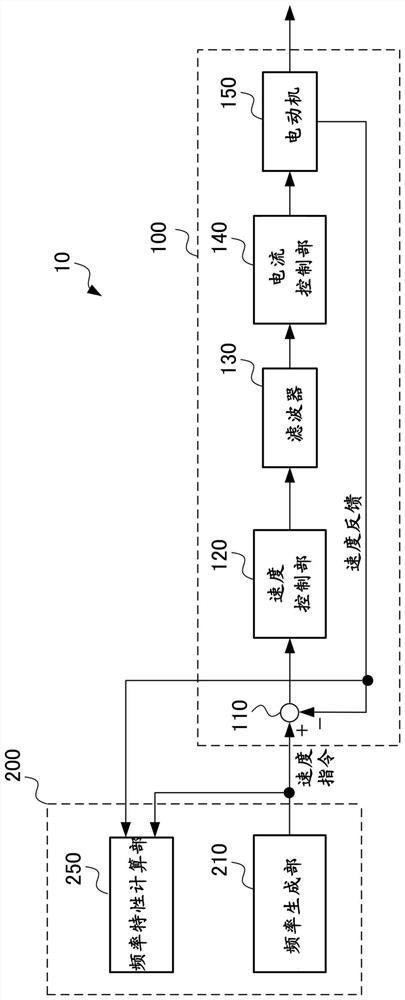

[0126] In the above-mentioned embodiment, the case of measuring the frequency characteristic (frequency response) of the control signal (speed command) is exemplified and explained by taking the motor with the load connected to the control device as an example. However, the frequency characteristic measuring unit does not have the frequency measurement target. Limited to this.

[0127] For example, such as Image 6 As shown, the frequency response when the sine wave interference generated by the frequency generating unit 210 is input to the speed command value generated by the speed command generating unit can also be measured. Thereby, for example, the speed control gain can be adjusted.

Deformed example 2

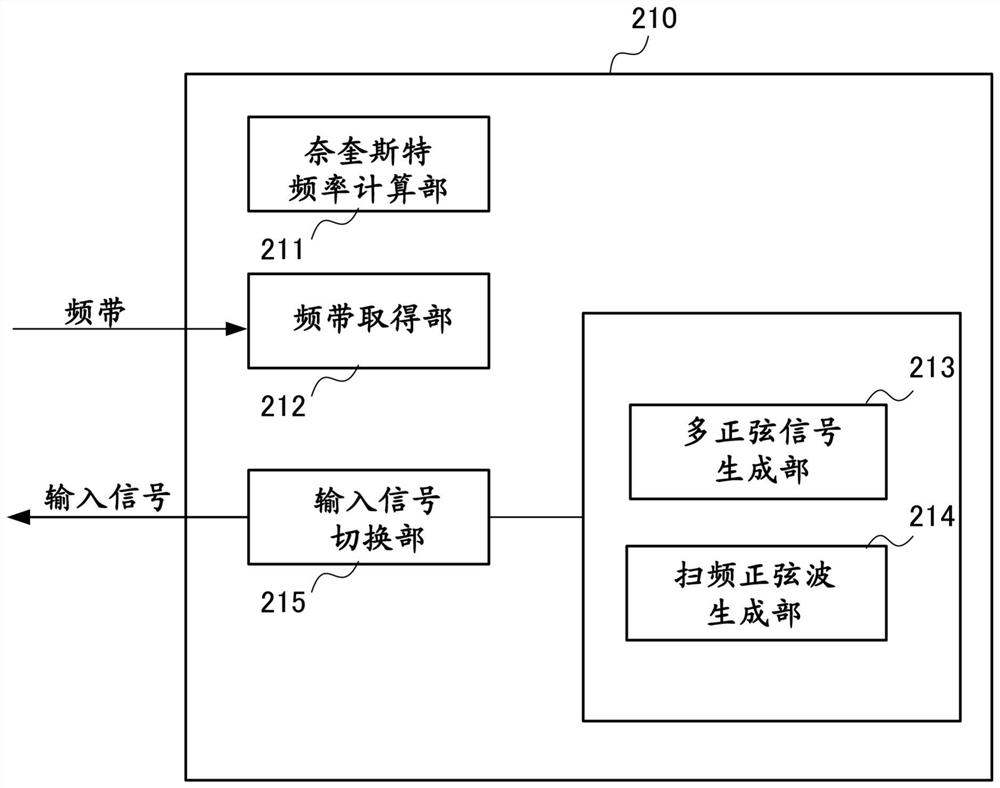

[0129] In the above-mentioned embodiment, the case of measuring the frequency characteristic (frequency response) of the speed command is exemplified and explained by taking the electric motor connected to the load as one control object, but the frequency measurement object of the frequency characteristic measuring unit is not limited to Speed command. It is also possible to measure the frequency characteristic (frequency response) of the input signal by using an arbitrary control object as the object to be measured.

[0130] It is also possible to measure the frequency characteristic (frequency response) of the input signal by using an input signal other than the speed command (for example, a torque command) as the object to be measured.

Deformed example 3

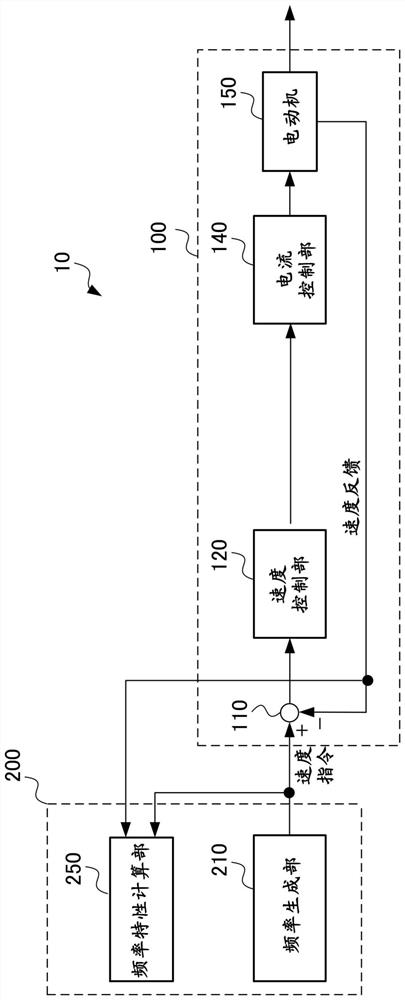

[0132] In the above-described embodiment, the control device 10 is configured to include the frequency characteristic measurement unit 200, but it is not limited to this.

[0133] For example, it may be provided as a frequency characteristic measuring device in which the frequency characteristic measuring unit 200 is independent, or may be provided as a single device. In addition, the frequency characteristic measurement unit 200 may be provided in the servo control unit 100. In addition, one of the frequency generation unit 210 and the frequency characteristic calculation unit 250 constituting the frequency characteristic measurement unit 200 may be provided in the control device 10 or the servo control unit 100. In addition, it may be provided as an independent device or as a single device.

[0134] In other words, the control device of the present disclosure can adopt various embodiments having the following structures.

[0135] (1) One mode of the frequency characteristic measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com