Double three-phase winding variable-flux memory motor, motor system and control method thereof

A memory motor, three-phase winding technology, applied in motor control, AC motor control, motor and other directions, can solve problems such as increasing the cost of the drive system, and achieve the effects of wide application, cost reduction, and rated capacity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

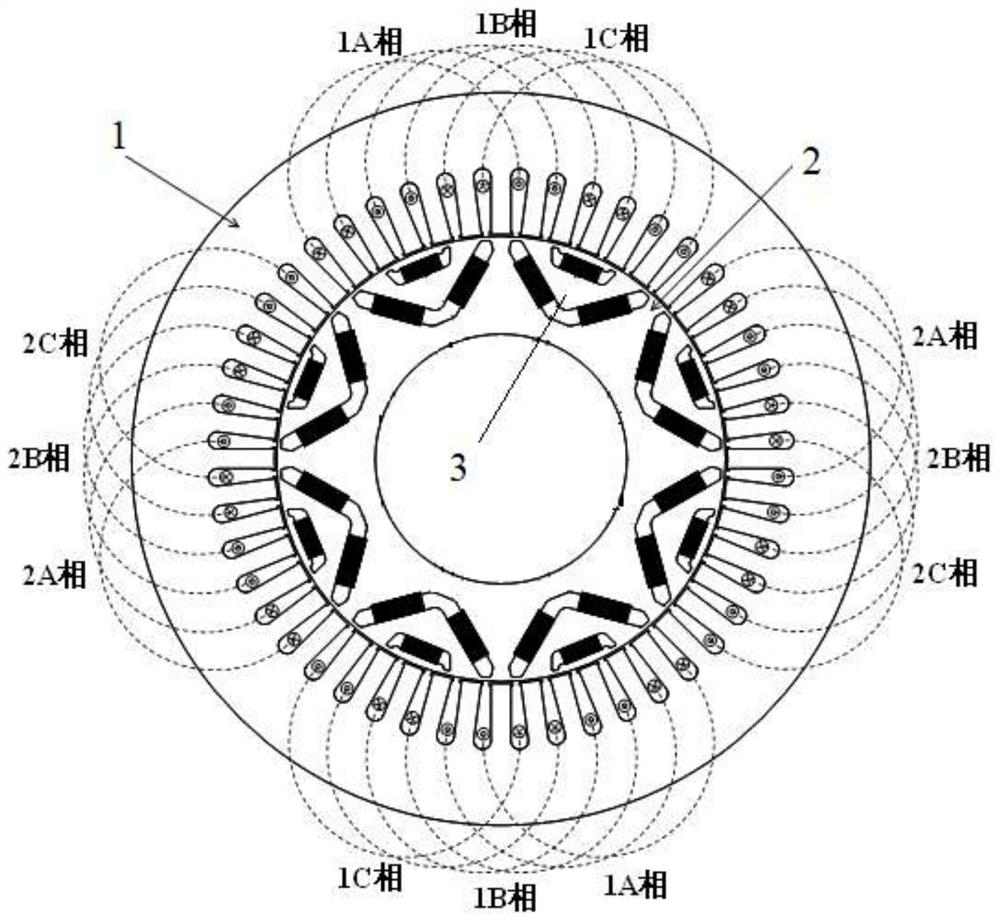

[0050] figure 1 It is a schematic cross-sectional structural diagram of a double-three-phase winding variable flux memory motor in an embodiment of the present invention.

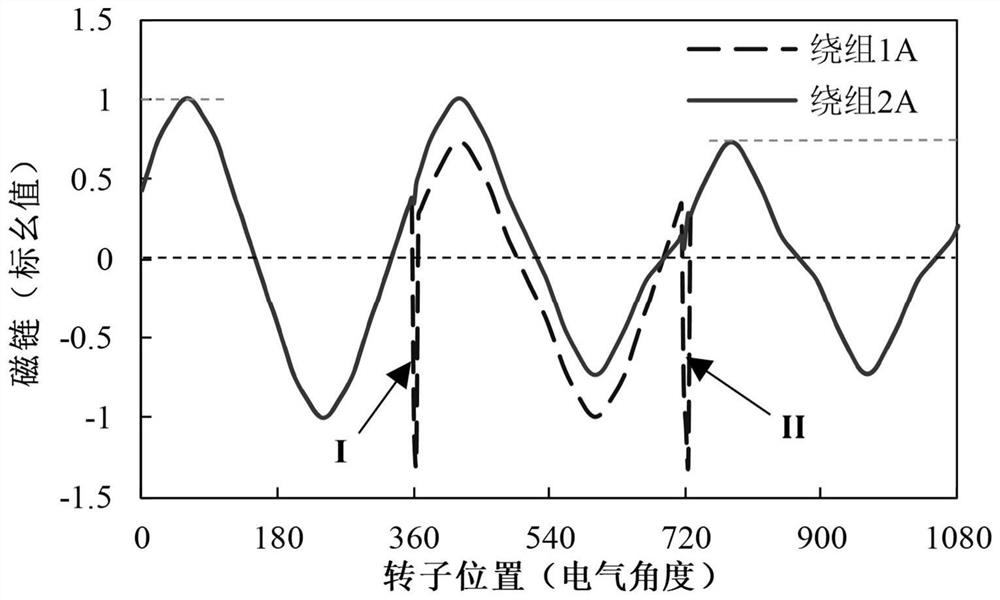

[0051] like figure 1 As shown, in this embodiment, the variable flux memory motor with dual three-phase windings has a stator with 48 slots and a rotor with 8 poles, which includes a stator 1, a rotor 2 and windings, wherein the rotor 2 is located inside the stator 1 (of course, In some other embodiments, it can also be made as an outer rotor structure, that is, the rotor 2 is located outside the stator 1). Both the stator 1 and the rotor 2 can be made of silicon steel punched sheets; the variable flux permanent magnet is placed on the rotor 2, that is, the position of the rotor pole 3, and the variable flux permanent magnet on the rotor can adopt high coercivity The hybrid permanent magnet scheme of constant flux permanent magnets and variable flux permanent magnets, that is to say, some permanent magnet...

Embodiment 2

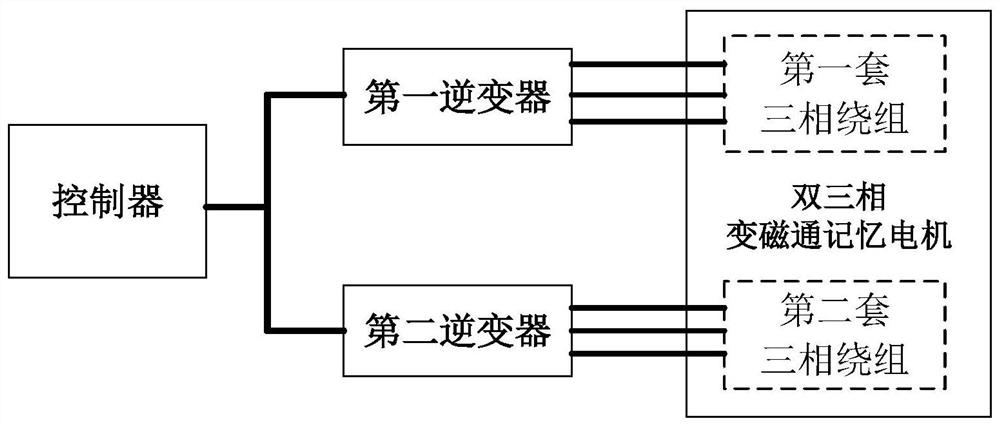

[0065] The structure of the variable flux memory motor system in embodiment 2 is basically the same as that of the variable flux memory motor system in embodiment 1, the difference is that the windings of the variable flux memory motor with double three-phase windings include the first A three-phase winding, a second three-phase winding, and a third three-phase winding, the spaces between the three-phase windings have no physical overlap, wherein the axes of the first three-phase winding, the second three-phase winding, and the third three-phase winding are positive For different rotor poles; when the variable flux permanent magnet needs to switch the magnetization state, only the first three-phase winding is loaded with magnetization or demagnetization current pulses to complete the magnetization state conversion of the variable flux permanent magnet, and the second , The third three-phase winding does not participate in the magnetization state conversion of the variable flux ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com