Continuous ore reduction and hot delivery steelmaking device

A preheating device and heat delivery technology, applied in the field of metallurgy, can solve the problems of unsuitable use of low-grade iron ore and non-coking coal, long production cycle of tunnel kiln method, and inability to match steelmaking, etc. The effect of small size, perfect sealing, and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

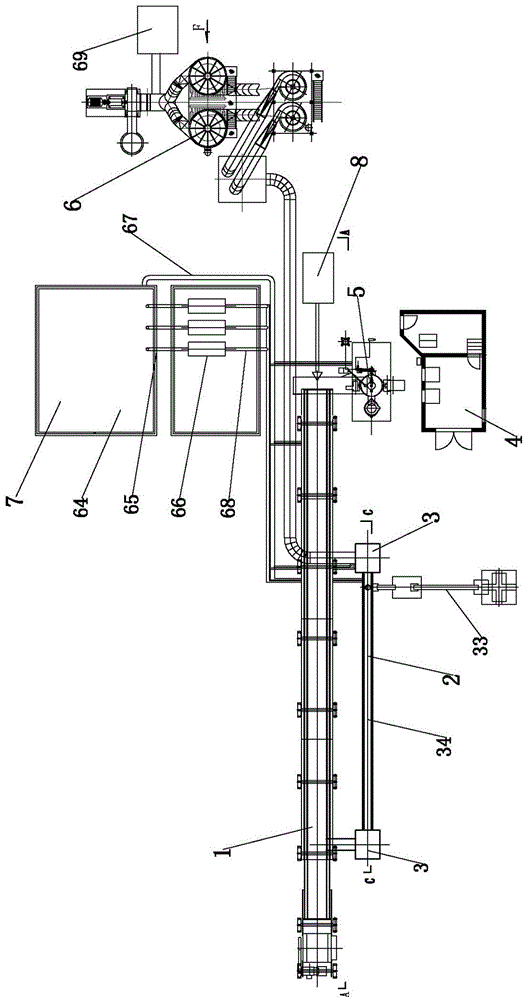

[0035] Such as figure 1 As shown, a continuous ore reduction and hot delivery steelmaking device includes a vibrating cyclone reduction furnace 1, an ore powder pelletizing preheating device 2 installed on one side of the vibrating cyclone reduction furnace, and one end of the vibrating cyclone reduction furnace The electric furnace melting and smelting device 5 and the fuel injection device 8, the dust removal device 6 connected to the ore powder pelletizing preheating device, the vibration cyclone reduction furnace, the mineral powder making pellet preheating device and the electric furnace melting and smelting device Water cooling device 7 and electrical control cabinet 4 for controlling the above components.

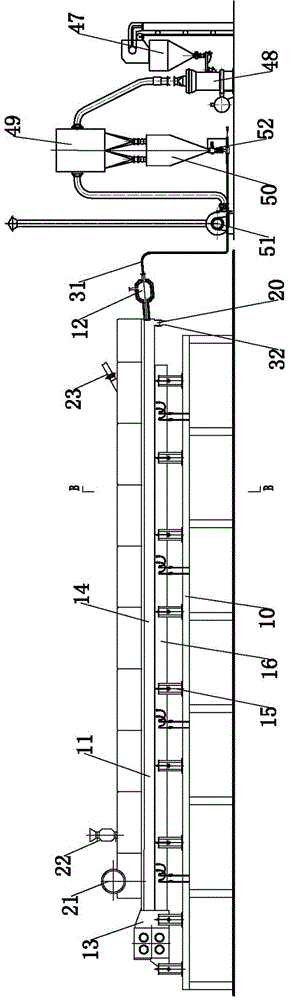

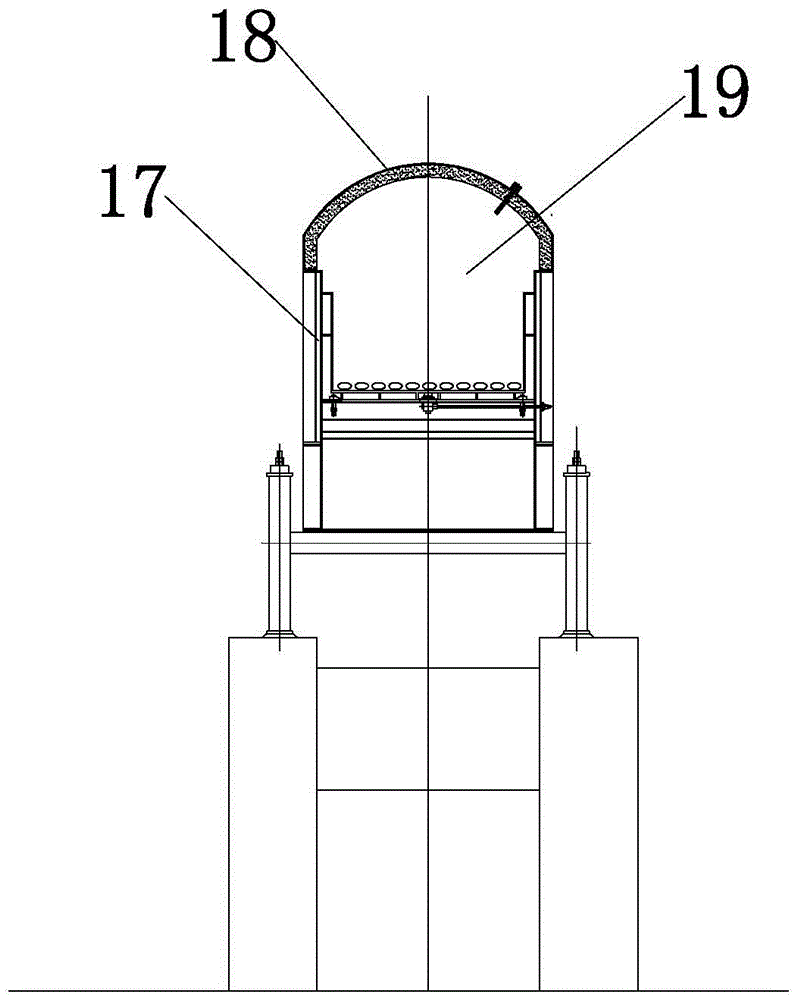

[0036] Such as figure 1 , 2, 3, the vibrating cyclone reduction furnace is an integrated device for pellet conveying, pellet reduction, and waste heat recovery. The vibrating cyclone reduction furnace includes a steel structure platform 10, a horizontal vibrating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com