A mechanical release coil system with handle

A technology of spring coil and handle, applied in the field of medical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

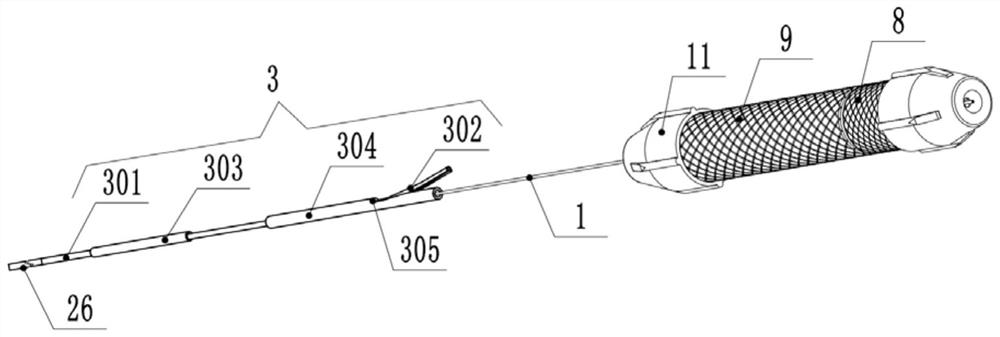

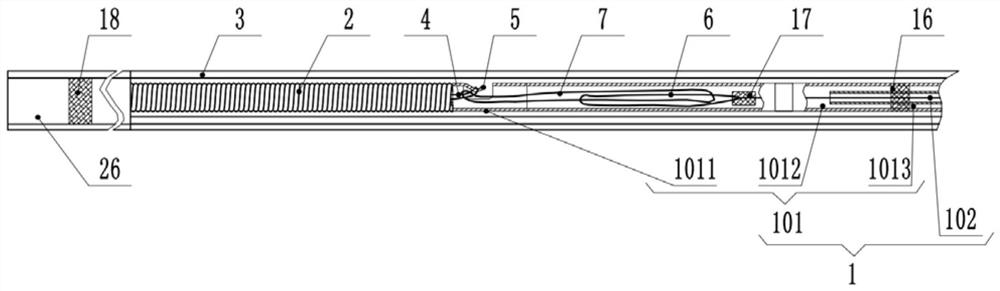

[0059] For the convenience of understanding, in this embodiment, the end close to the operator is defined as the proximal end ( figure 1 the right end of the corresponding handle in the figure 1 Corresponding to the left end of the microcatheter 26 in the middle), the proximal end or the distal end indicated for each component hereinafter refers to the above description.

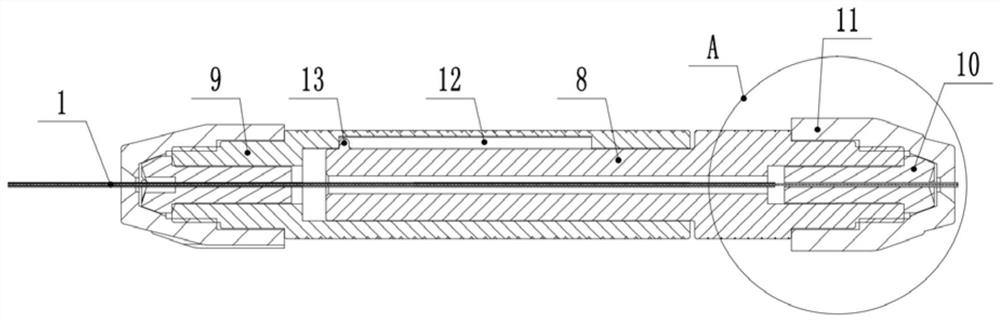

[0060] Embodiment 1 is basically as attached Figure 1-Figure 7 Shown: a mechanical release spring coil system with a handle, including a push guide wire 1 and a spring coil 2 connected to the distal end of the push guide wire 1, the proximal end of the push guide wire 1 is connected with a handle, and also includes a Install the spring coil 2 and push the guide wire 1 into the introducer sheath 3. It should be pointed out that, as a standard part on the market, the microcatheter 26 is a component that needs to be used together with the coil system in the present application during the operation. During th...

Embodiment 2

[0082] The difference between the second embodiment and the first embodiment is: as Figure 8 As shown, in this embodiment, the inner wall of the distal handle 9 is provided with a second guide groove 19 staggered from the first guide groove 12, the second guide groove 19 is arranged in parallel with the first guide groove 12, and the first guide groove 19 is arranged in parallel with the first guide groove 12. An annular groove 20 is opened between the distal end of the guide groove 12 and the proximal end of the second guide groove 19. The annular groove 20 spans the circumferential direction of the distal handle 9 with an amplitude of 15° to 345°. In this embodiment, the annular groove 20 spans The amplitude is 20°.

[0083] In the first embodiment, during the disengagement stage of the spring coil 2 (corresponding to step 3), after the disengagement of the spring coil 2 is completed, continue to push image 3 The proximal handle 8 is far away from the distal handle 9 and ...

Embodiment 3

[0085] The difference between the third embodiment and the first embodiment is that in the first embodiment, the proximal end of the distal handle 9 is sleeved outside the distal end of the proximal handle 8, while in this embodiment, as another setting form, such as Figure 9 As shown, the distal end of the proximal handle 8 is sleeved outside the proximal end of the distal handle 9. Correspondingly, the first guide groove 12 is provided on the inner wall of the proximal handle 8, and the protrusion 13 is provided on the inner wall of the proximal handle 8. On the outer wall of the distal handle 9 ( Figure 9 The first guide groove 12 and the protrusion 13 are not shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com