Electric cable storage winch control device and control method thereof

The technology of a control device and control method is applied to hoisting devices and clockwork mechanisms, etc., which can solve the problems of not being able to adapt to cables of different diameters, effort, and inflexibility of the system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

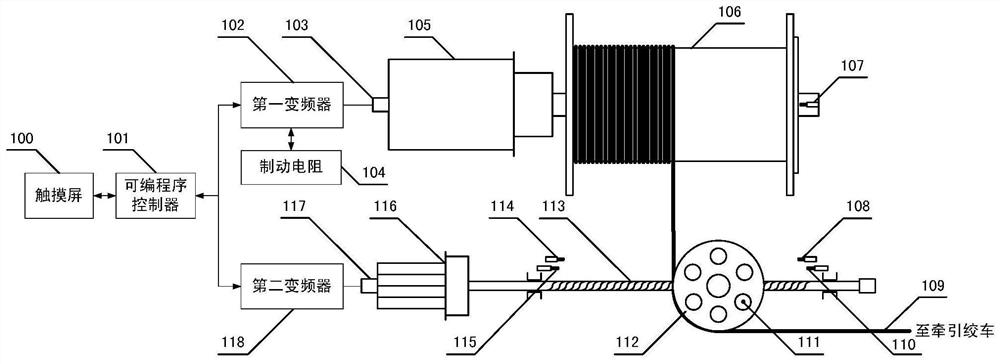

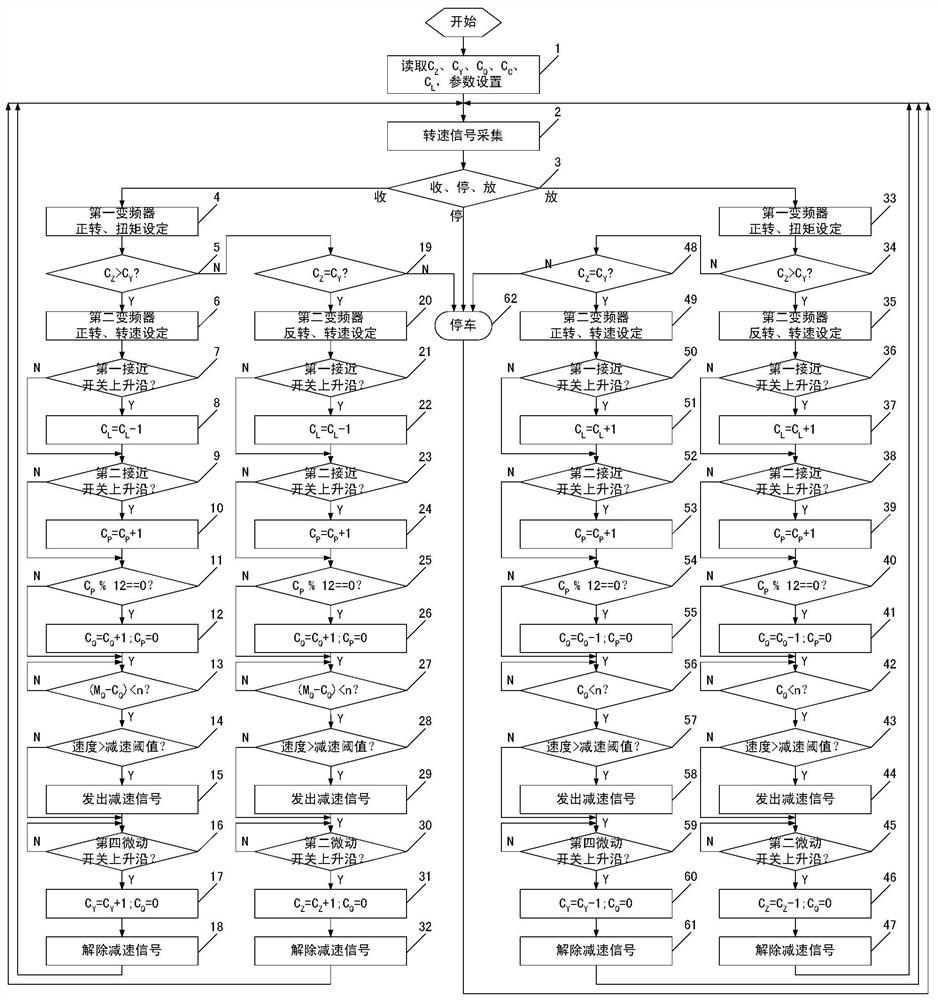

[0087] Such as figure 1 Shown is a composition diagram of an electric cable storage winch control device of the present invention, which consists of a first micro switch 115, a second micro switch 114, a third micro switch 110, a fourth micro switch 108, a first Proximity switch 111, second proximity switch 107, first frequency converter 102, second frequency converter 118, first deceleration motor 105, second deceleration motor 116, first encoder 103, second encoder 117, programmable control Device 101, touch screen 100, brake resistor 104, cable storage reel 106, cable guide wheel 112, cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com