Method for removing hydrogen impurities in CO feed gas by using three-stage catalyst filling method

A catalyst and raw material gas technology, which is applied in the field of dehydrogenation purification process of CO raw material gas in the coal-to-ethylene glycol technology, can solve the problems of high operating energy consumption, many hidden dangers in equipment safety, and high manufacturing cost, and achieves the improvement of reaction temperature, The effect of reducing the risk of high temperature sintering and improving the efficiency of low temperature dehydrogenation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

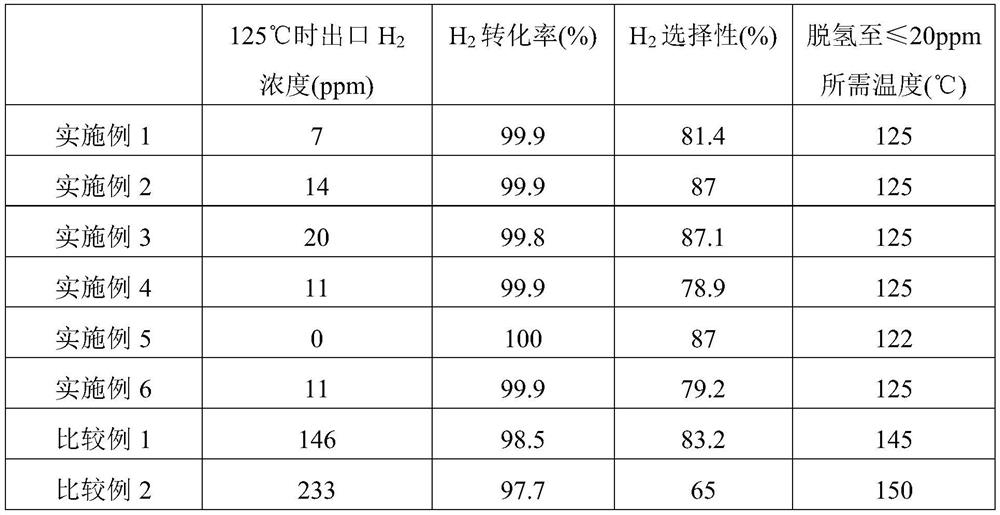

Examples

Embodiment 1

[0021] Preparation of three catalysts:

[0022] Weigh Al 2 O 3 The powder was placed in a palladium active component solution with a concentration of 0.02mol / L for 6h; after filtration, the product was placed in an oven at 100°C for drying for 10h, and then placed in a muffle furnace for calcination at 250°C for 8h; the calcined product was mixed with chloride Ammonium was mixed in a molar ratio of 1:0.2 and then placed in H 2 PdCl was obtained by treating at 350℃ for 3h in the atmosphere x / Al 2O 3 , marked as GL-1, in which the mass percentage of Pd is 1 wt%.

[0023] Weigh CeO 2 20wt% CeO 2 -Al 2 O 3 The powder was placed in a palladium active component solution with a concentration of 0.02mol / L for 20h; after filtration, the product was dried in an oven at 100°C for 10h, and then placed in a muffle furnace for calcination at 450°C for 8h; the calcined product was soaked in Stir in NaOH-NaHCO3 solution with a concentration of 0.1mol / L for 6h, filter and dry it and...

Embodiment 2

[0029] The preparation method of the catalyst is the same as that in Example 1.

[0030] Three-stage removal of H in CO feed gas 2 Impurities: The catalyst is filled according to the ratio of Pd moles: GL-1=25%, GL-2=50%, GL-3=25%, and 12.5g GL-3, 25g GL-2, 12.5g GL are filled in sequence -1 into the bed, others are the same as in Example 1. The catalyst dehydrogenation results are shown in Table 1.

Embodiment 3

[0032] The preparation method of the catalyst is the same as that in Example 1.

[0033] Three-stage removal of H in CO feed gas 2 Impurities: The catalyst is filled according to the ratio of Pd moles: GL-1=15%, GL-2=70%, GL-3=15%, and fill 7.5g GL-3, 35g GL-2, 7.5g GL in sequence -1 into the bed, others are the same as in Example 1. The catalyst dehydrogenation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com