A multi-channel temperature control device for semiconductor coating equipment

A technology of coating equipment and temperature control device, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., and can solve problems such as rising, low equipment production capacity, and film failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

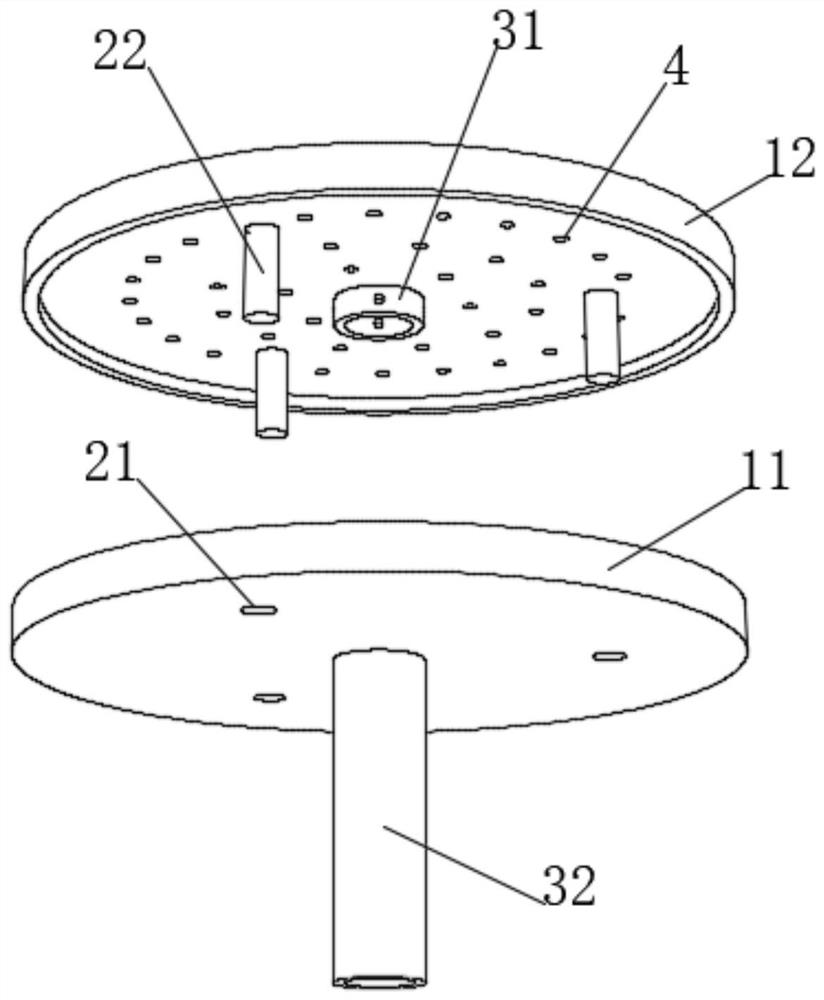

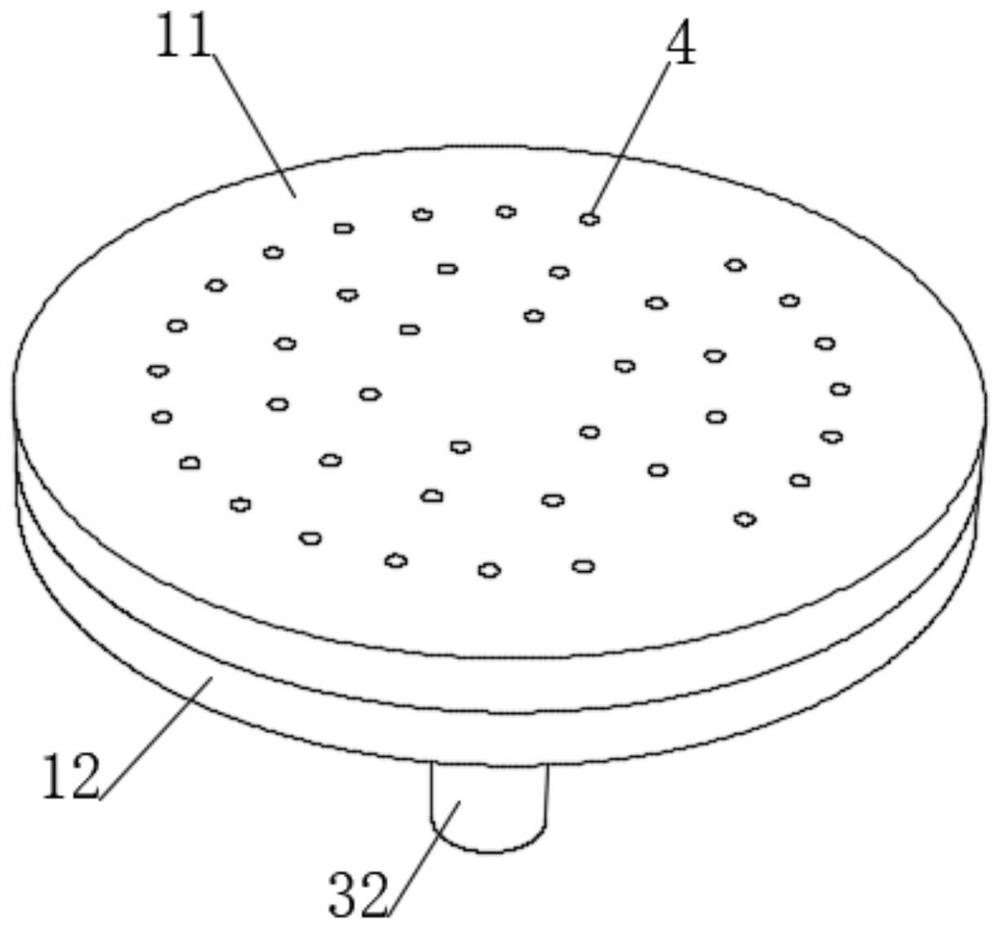

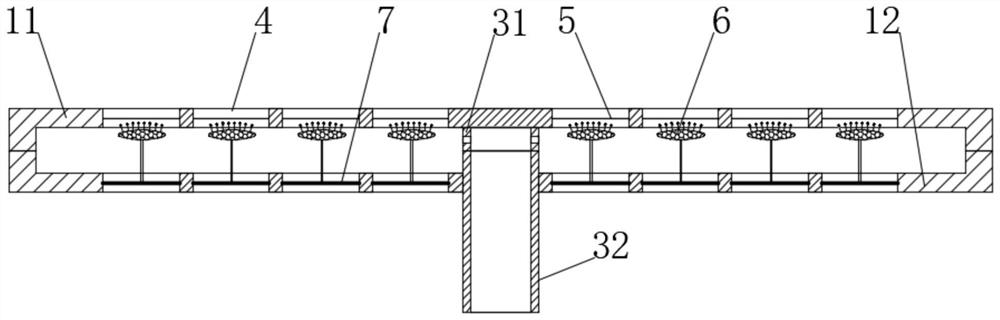

[0040] See Figure 1-2 , The multi-channel temperature control apparatus for coating a semiconductor device comprising mutually matching the thermally conductive pad 11 and a lower thermally conductive plate 12, the thermal pad 12 is formed between the medium of the dispersion chamber 11 and a lower thermally conductive plate, a thermally conductive plate 12 at the lower end ceramic rod is fixedly connected with a plurality of uniformly distributed 22, a plurality of cut ends of the ceramic rod 22 matches the mounting hole 21 on the heat-conducting plate 11, the lower end of the heat-conducting plate 11 is fixedly connected with an external bulk gas passage 32, the heat conducting plate 12 has a lower end fixedly connected to the upper portion 32 matches the outer diffuser passageway within the diffuser passage 31, the outer end of the inner diffuser 31 drilled with a plurality of vent passage, vent chamber communicates with the dispersing medium, the heat-conducting plate 11 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com