Pump unit

A pump unit and pump body technology, which is applied in the field of circulating pumps, can solve the problems of complex pump unit structure, complex assembly process, and long assembly time, and achieve the effects of saving raw material costs, high space utilization, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Here, the following examples of the present invention are used to illustrate the present invention, but not to limit the scope of the present invention.

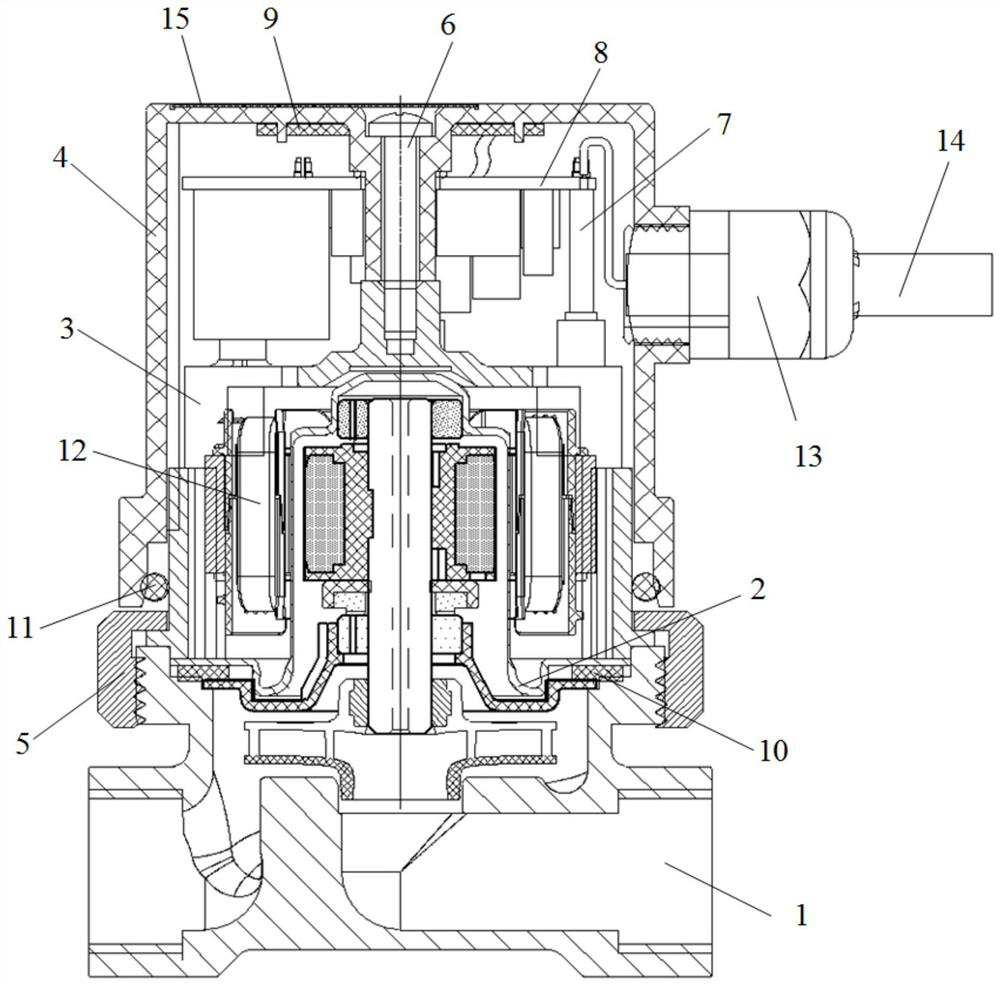

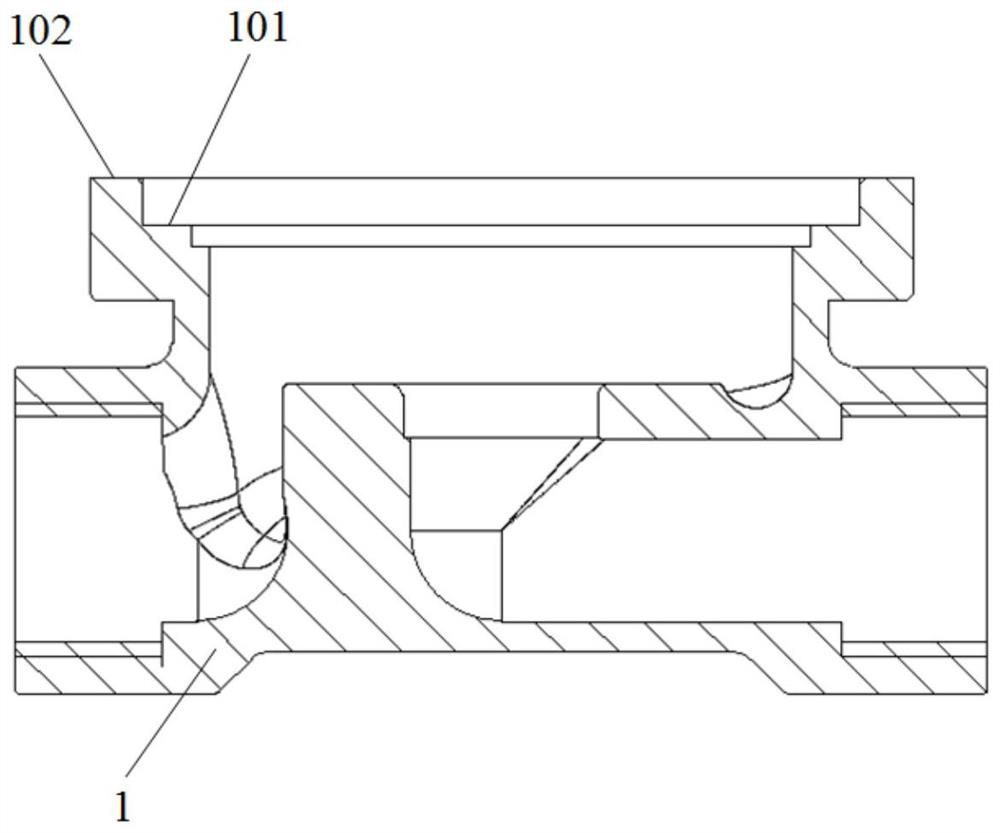

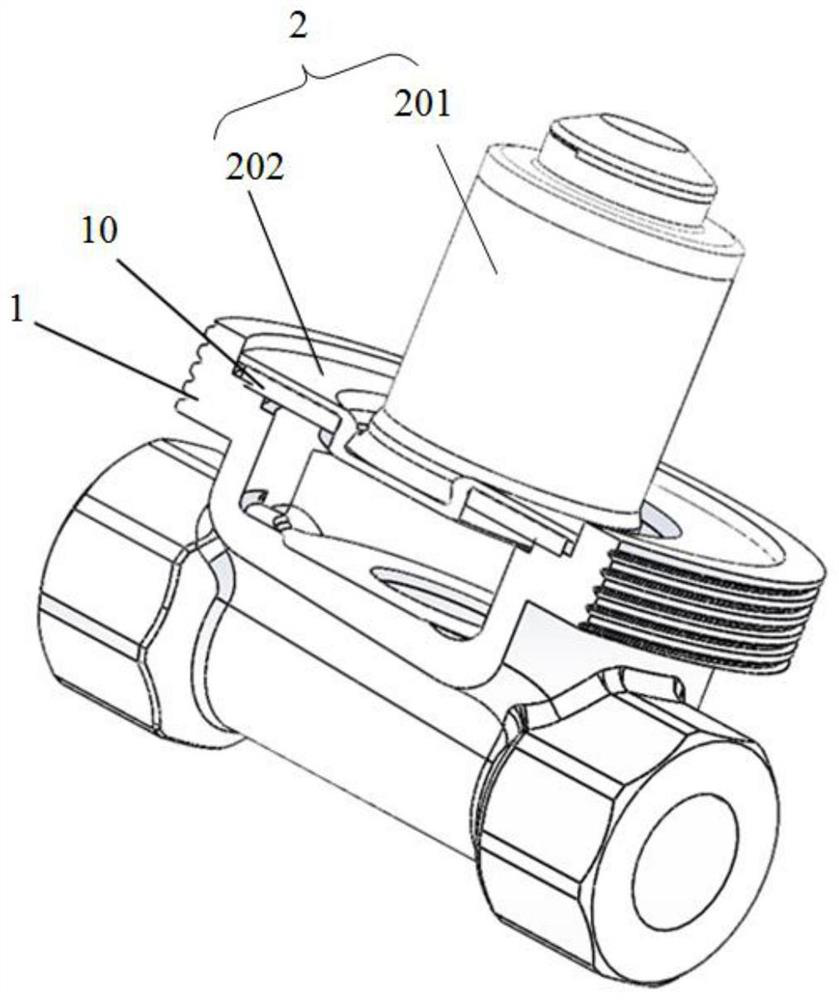

[0034] Such as figure 1 As shown, a pump unit provided by an embodiment of the present invention includes: a pump body 1 , a stator shielding sleeve 2 , a motor housing 3 and a junction box housing 4 . The pump body 1 is arranged at the bottom of the pump unit; figure 2 and image 3 As shown, the stator shielding sleeve 2 is arranged above the pump body 1, the upper part of the stator shielding sleeve 2 is a cylindrical part 201 with an open lower end, and the cylindrical part 201 is set on the outside of the rotor; the bottom of the cylindrical part 201 is along its radial direction A flange portion 202 is arranged outwardly, and the flange portion 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com