Old dam dismantling method

A technology for dams and dam sections, which is applied in the field of demolition of old dams, can solve problems such as the inability to fundamentally solve the hidden dangers of old dams, and achieve the effects of eliminating hidden dangers, slowing down water storage speed, and reducing potential energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

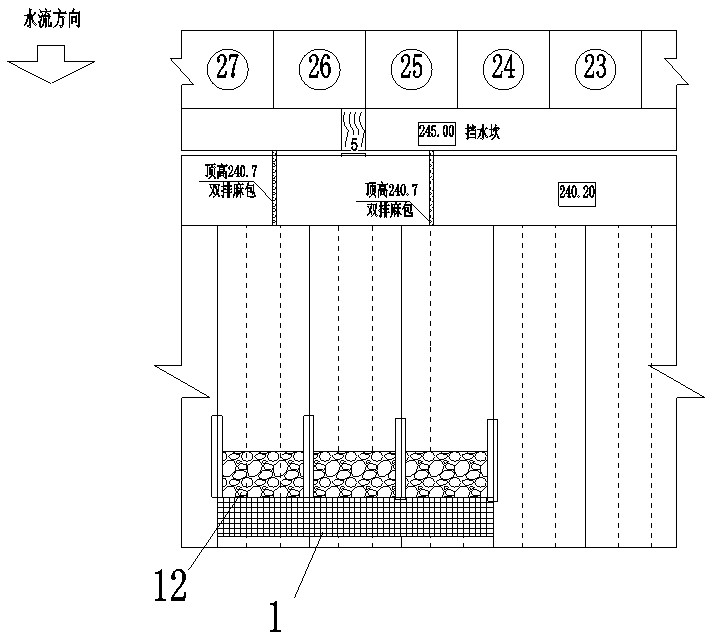

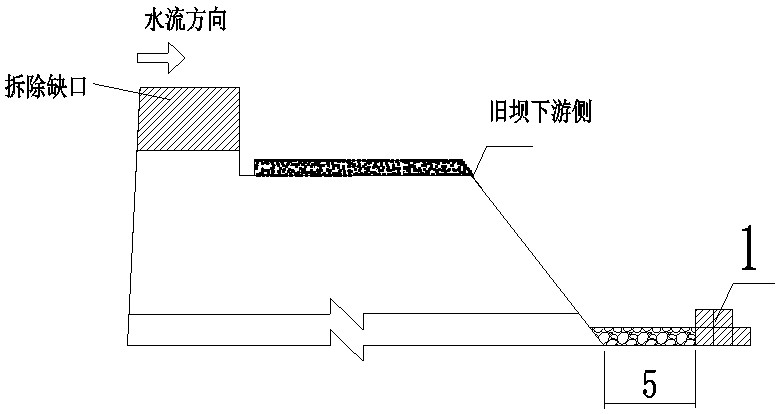

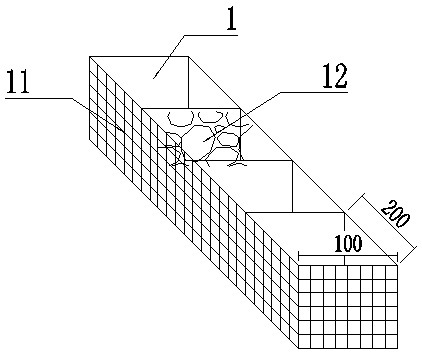

[0026]Concrete embodiment: the elevation of the new dam is EL175.0-EL269.5m, the elevation of the bottom of the dam is EL175m, the height is 94.50m, and the normal storage level is EL263.5m; the elevation of the old dam is EL176.0-EL267.7, and the elevation of the bottom of the dam is 176m, height 91.7m, normal storage level EL240.8m, the total capacity between the two is 3.6 million m 3 , The total width of the old dam is 1080m, divided into 1-60# dam sections, retaining the old dam main body 1-5# dam section, 44-60# dam section, demolishing the middle part, blasting the middle part of the old dam, blasting the downstream side of the old dam EL267.70~EL239.90 (91.7-63.9m), the lowest surface is located at 0.9 meters underwater, leaving a concrete wall with the thickness of the upstream side* and the height difference between the downstream side=3m*5.1m as the water retaining sill, and the water surface height is 4.2 m, arrange the site before filling and storing the old and n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com