Binding post machining device and method

A processing device and processing method technology, applied to electrical components, relays, circuits, etc., can solve the problems of reducing sheet resistance, destroying the surface layer, and unable to completely remove the surface layer of the terminal, so as to ensure contact performance and reduce contact resistance , The effect of reducing the sheet resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

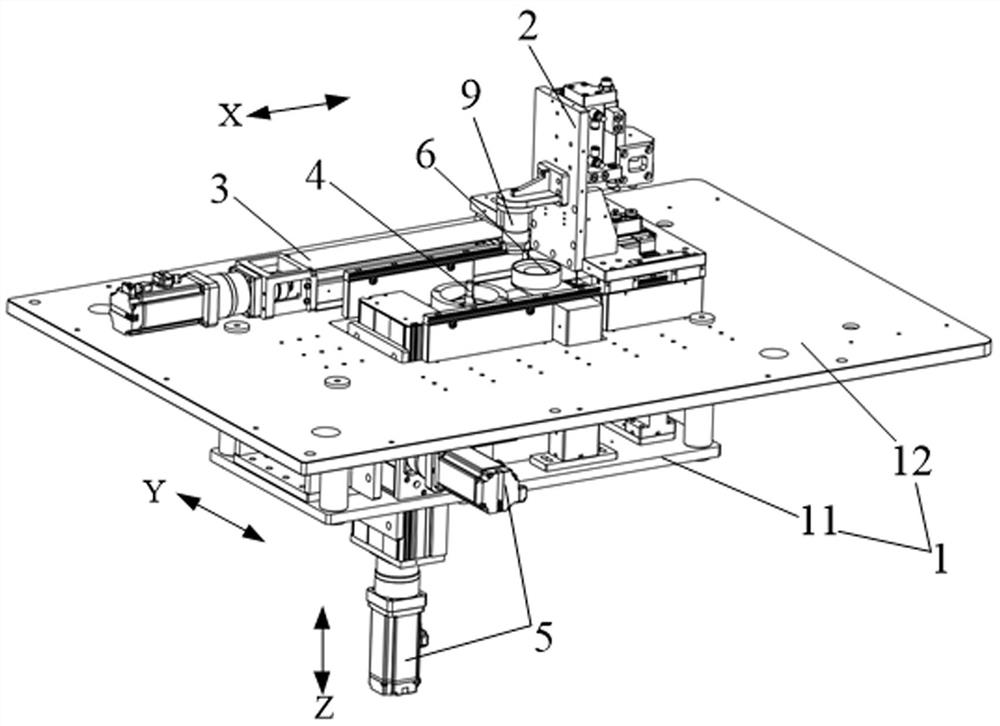

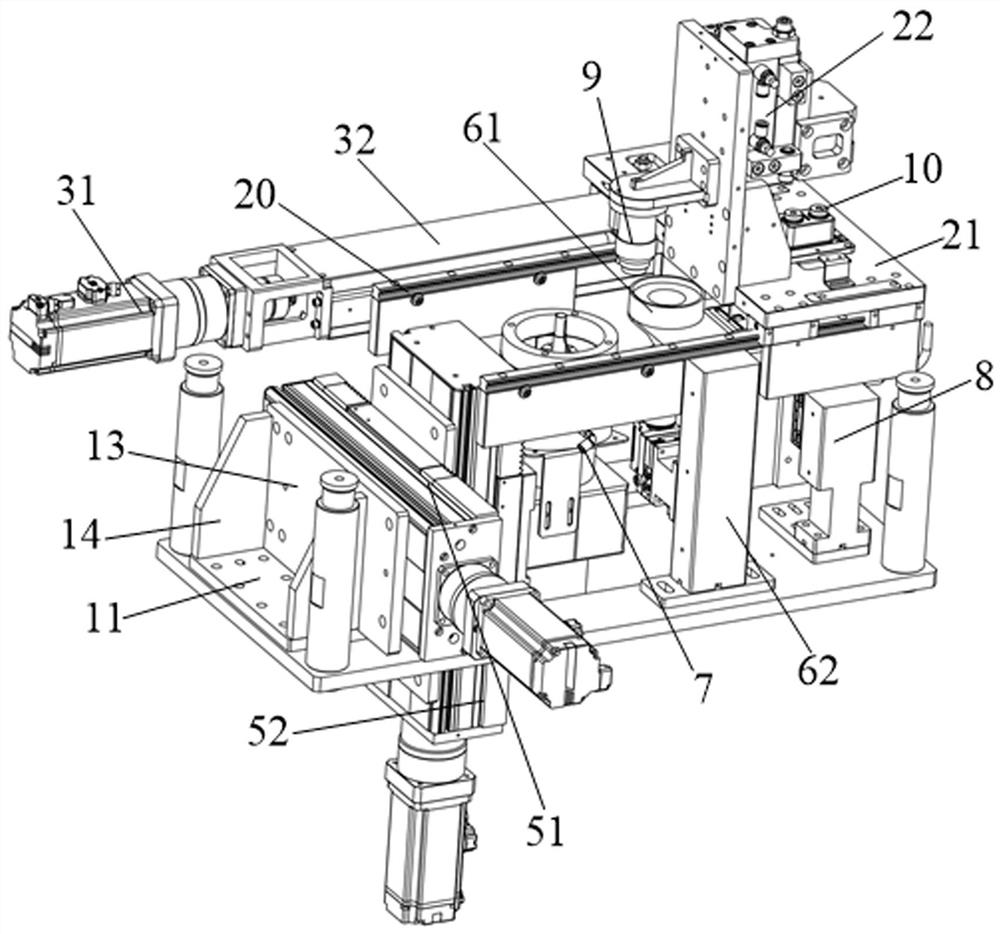

[0049] This embodiment provides a terminal post processing device, capable of milling the terminal post, so that the sheet resistance of the post-processed post can be reduced, thereby reducing the contact resistance of the relay.

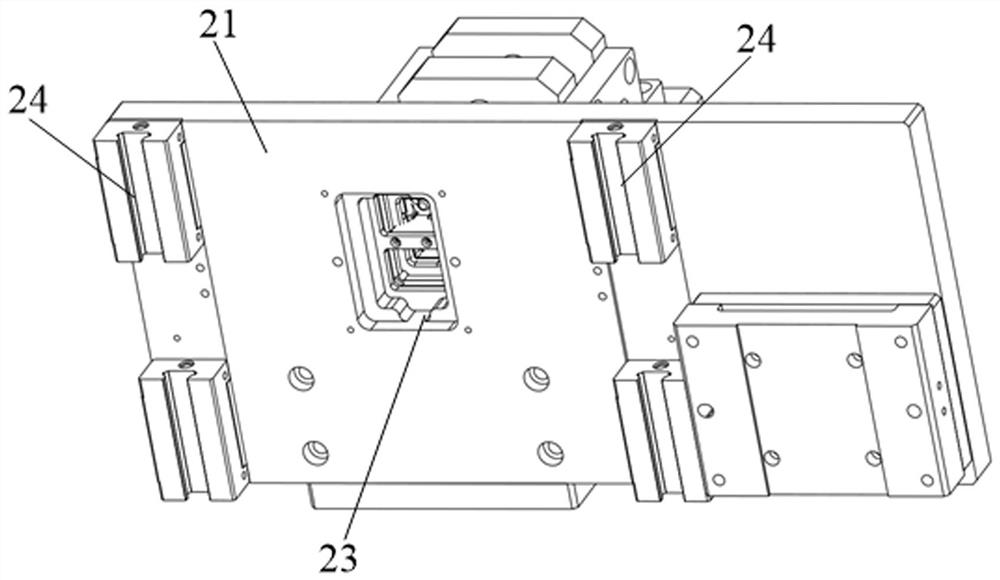

[0050] Such as Figure 1 to Figure 5 As shown, the terminal post processing device includes a fixing seat 1 , a product fixing structure 2 , a first driving mechanism 3 , a milling mechanism 4 and a second driving mechanism 5 . The fixing seat 1 includes a base plate 11 , a fixing plate 12 , a side plate 13 and a reinforcing plate 14 . Wherein, the bottom plate 11 and the fixed plate 12 are fixedly connected by the fixed column, the side plate 13 is connected between the bottom plate 11 and the fixed plate 12, and the reinforcement plate 14 is respectively connected with the bottom plate 11 and the side plate 13, and is used to increase the size of the bottom plate 11 and the side plate. 13 between connection strengths.

[0051] Wherein, the prod...

Embodiment 2

[0067] This embodiment provides a terminal post processing method, which can be applied to the terminal post processing device in the first embodiment, such as Figure 6 As shown, the terminal post processing method includes the following steps:

[0068] S1. Fix the ceramic component 30 on the product fixing structure 2 , and control the bottom end of the terminal post 10 in the ceramic component 30 to pass through the through hole 23 on the product fixing structure 2 .

[0069] The ceramic component 30 can be manually fixed on the product fixing structure 2, and the bottom end of the terminal 10 can be passed through the through hole 23, and the ceramic component 30 can also be fixed on the product fixing structure 2 by a manipulator, and the terminal The bottom end of 10 passes through the through hole 23 .

[0070] S2. Drive the product fixing structure 2 to move in the first horizontal direction X through the first driving mechanism 3, so that the plane where the axis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com