Antistatic touch screen protective film

A touch screen and antistatic technology, which is applied in the field of antistatic touch screen protective film and its preparation, can solve the problems of poor antistatic performance of touch screen protective film, achieve antistatic, improve antistatic performance, and reduce sheet resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method for an antistatic touch screen protective film, comprising the following steps:

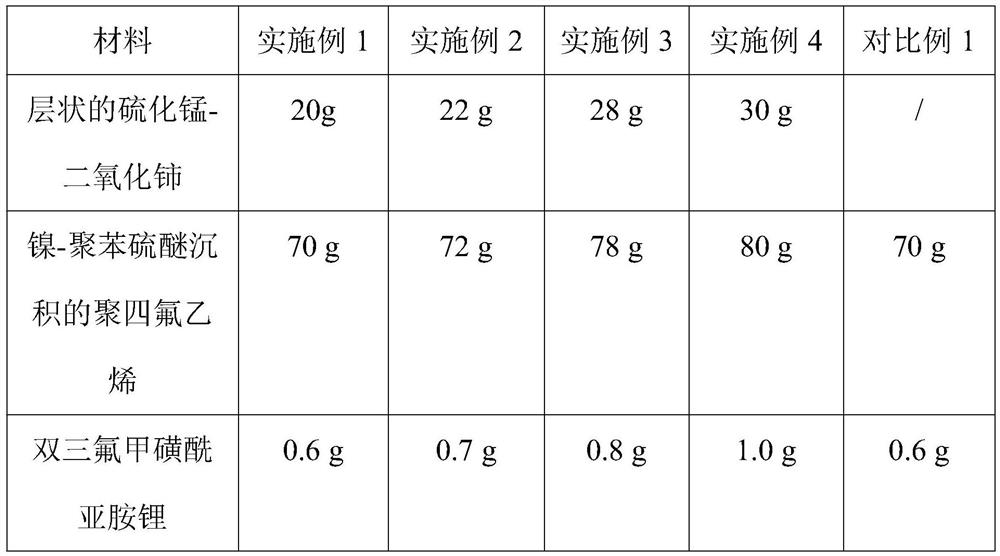

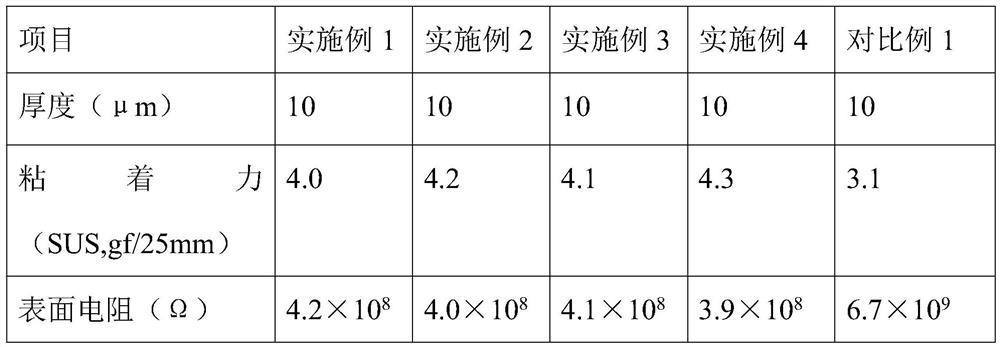

[0022] Mass ratio: the mass ratio of cerium nitrate hexahydrate, distilled water, urea, ethylenediamine, dodecyl mercaptan, dodecylamine, silver sulfide catalyst, and manganese dibutyldithiocarbamate is 1.4:25:4.2: 8:7:4:1:0.02, the mass ratio of nickel powder and polyphenylene sulfide powder is 10:15, layered manganese sulfide-cerium dioxide, nickel-polyphenylene sulfide deposited polytetrafluoroethylene, double The mass ratio of lithium trifluoromethanesulfonyl imide is 20:70:0.6.

[0023] (1) Weigh cerium nitrate hexahydrate and add it to distilled water, then add urea, ethylenediamine, dodecylmercaptan, dodecylamine, silver sulfide catalyst, and manganese dibutyldithiocarbamate to mix, stir and transfer to Reaction in the reaction kettle, the stirring time is 30min, the reaction temperature is 120°C, the reaction time is 48h, after the reaction is completed, the w...

Embodiment 2

[0027] A preparation method for an antistatic touch screen protective film, comprising the following steps:

[0028] Mass ratio: the mass ratio of cerium nitrate hexahydrate, distilled water, urea, ethylenediamine, dodecyl mercaptan, dodecylamine, silver sulfide catalyst, and manganese dibutyldithiocarbamate is 1.45:26:4.4: 9:8:5:2:0.03, the mass ratio of nickel powder and polyphenylene sulfide powder is 12:16, layered manganese sulfide-cerium dioxide, nickel-polyphenylene sulfide deposited polytetrafluoroethylene, bis The mass ratio of lithium trifluoromethanesulfonyl imide is 22:72:0.7.

[0029] (1) Weigh cerium nitrate hexahydrate and add it to distilled water, then add urea, ethylenediamine, dodecylmercaptan, dodecylamine, silver sulfide catalyst, and manganese dibutyldithiocarbamate to mix, stir and transfer to Reaction in the reactor, the stirring time is 32min, the reaction temperature is 130°C, the reaction time is 48.5h, after the reaction is completed, the water and...

Embodiment 3

[0033] A preparation method for an antistatic touch screen protective film, comprising the following steps:

[0034] Mass ratio: the mass ratio of cerium nitrate hexahydrate, distilled water, urea, ethylenediamine, dodecyl mercaptan, dodecylamine, silver sulfide catalyst, and manganese dibutyldithiocarbamate is 1.5:28:4.8: 11:9:6:3:0.08, the mass ratio of nickel powder and polyphenylene sulfide powder is 18:19, layered manganese sulfide-cerium oxide, nickel-polyphenylene sulfide deposited polytetrafluoroethylene, double The mass ratio of lithium trifluoromethanesulfonyl imide is 28:78:0.8.

[0035](1) Weigh cerium nitrate hexahydrate and add it to distilled water, then add urea, ethylenediamine, dodecylmercaptan, dodecylamine, silver sulfide catalyst, and manganese dibutyldithiocarbamate to mix, stir and transfer to Reaction in the reactor, the stirring time is 44min, the reaction temperature is 150°C, and the reaction time is 49h. After the reaction, the water and alcohol ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com