Three-dimensional memory structure and its preparation method

A memory, three-dimensional technology, used in semiconductor devices, electrical solid devices, electrical components, etc., can solve problems such as gate layer short-circuit and gate layer breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

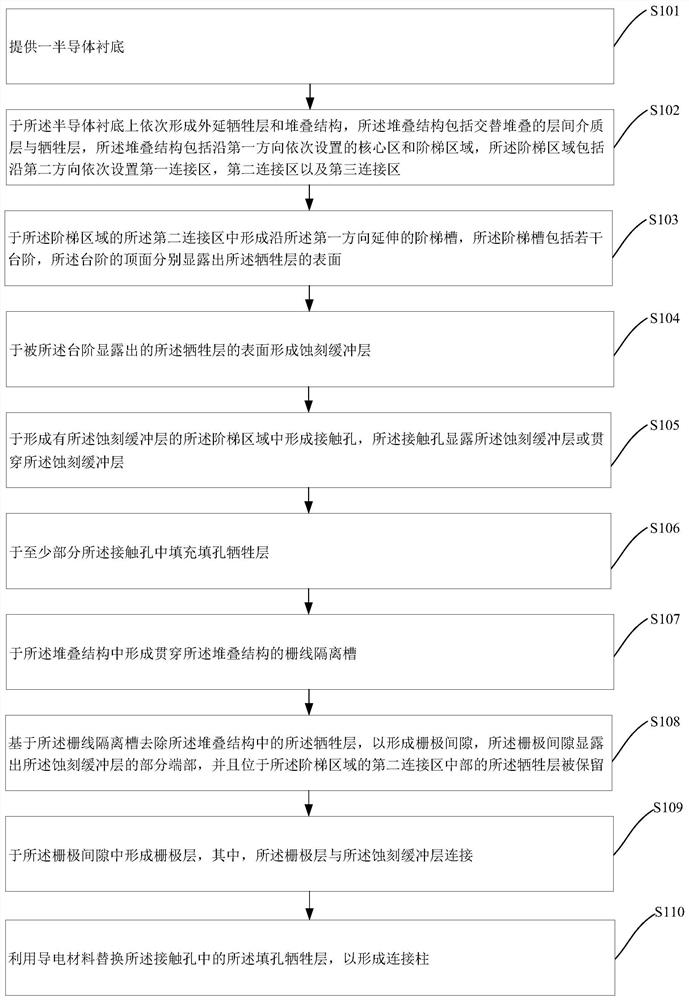

[0154] figure 1 A flow chart of preparing a three-dimensional memory structure according to an embodiment of the present invention is shown. see figure 1 , the preparation method of the three-dimensional memory structure includes:

[0155] Step S101, providing a semiconductor substrate;

[0156] Step S102, sequentially forming an epitaxial sacrificial layer and a stacked structure on the semiconductor substrate, the stacked structure includes alternately stacked interlayer dielectric layers and sacrificial layers, and the stacked structure includes core regions and a stepped area, the stepped area includes a first connection area, a second connection area and a third connection area arranged in sequence along the second direction;

[0157] Step S103, forming a stepped groove extending along the first direction in the second connection region of the stepped region, the stepped groove includes a plurality of steps, and the top surfaces of the steps respectively expose the sac...

Embodiment 2

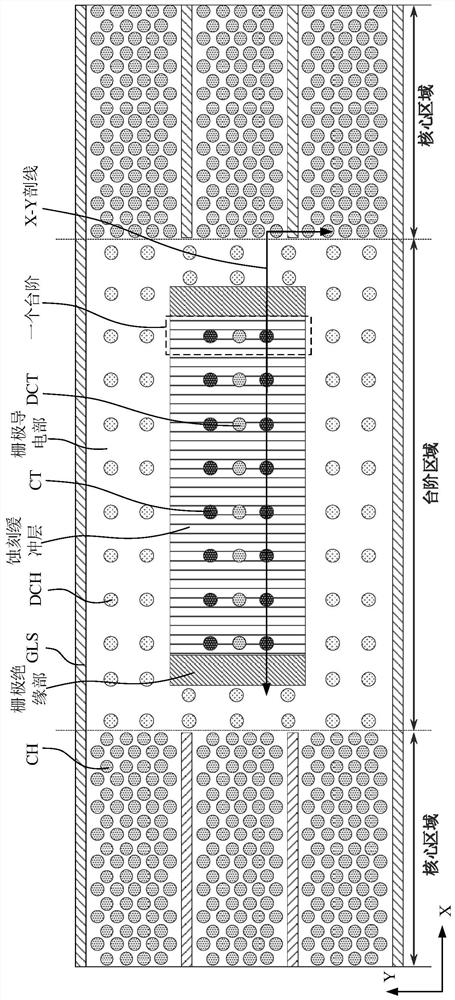

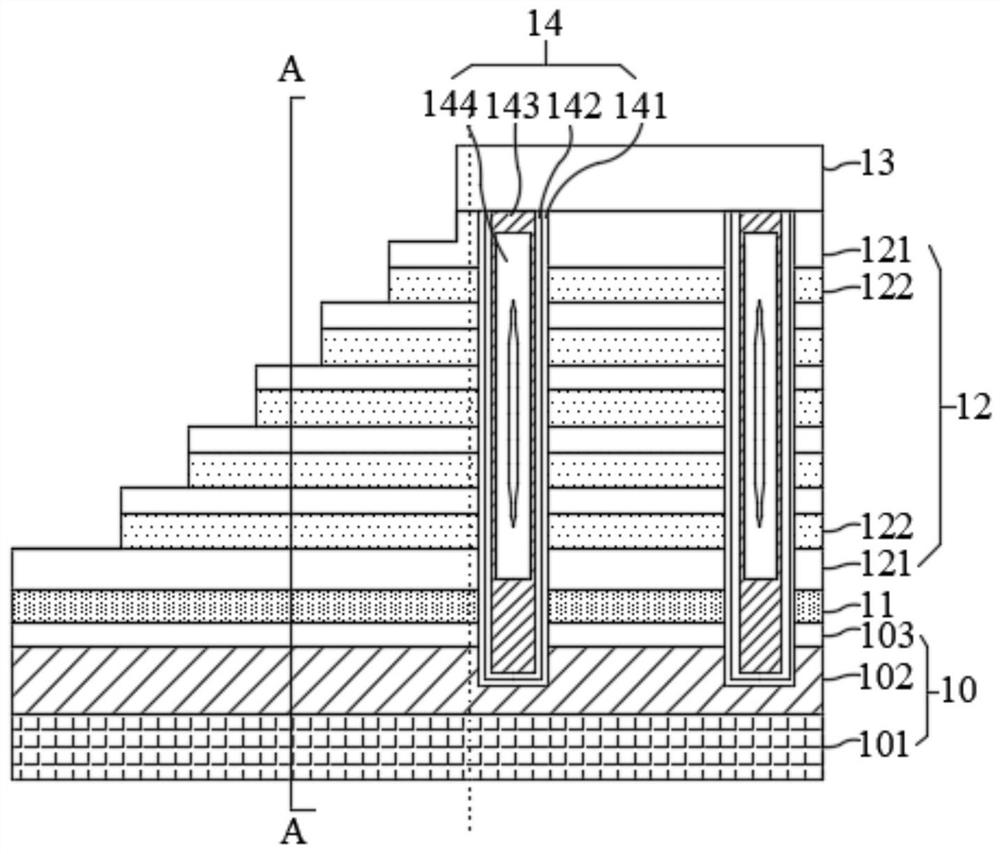

[0197] see figure 2 as well as Figure 31-33 The present invention also provides a three-dimensional memory structure prepared by the preparation method in Embodiment 1, the three-dimensional memory structure at least includes a semiconductor substrate 10, an epitaxial layer 28, a stacked gate structure 30, several steps, and an etching buffer layer 18 and some connecting columns 32 ( figure 2 CT in ). The three-dimensional memory structure of this embodiment can reduce the process difficulty of etching the contact hole 20 in the stepped area, eliminate the word line bridge (Word Line Bridge) of different layers caused when the contact hole 20 is etched during the etching process (Punch), and improve the three-dimensional memory. performance of the piece.

[0198] see figure 2 as well as Figure 31-33 , in this embodiment, the semiconductor substrate 10 includes a substrate body 101, and a doped well 102 is formed in the substrate body 101 by a doping process. The sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com