High-precision follow-up system

A follow-up system, high-precision technology, applied to the parts of TV system, TV, color TV, etc., can solve the problems of monitoring dead angle, poor pointing accuracy, and unable to adjust the monitoring angle by itself, so as to improve real-time performance , Improve the effect of tracking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

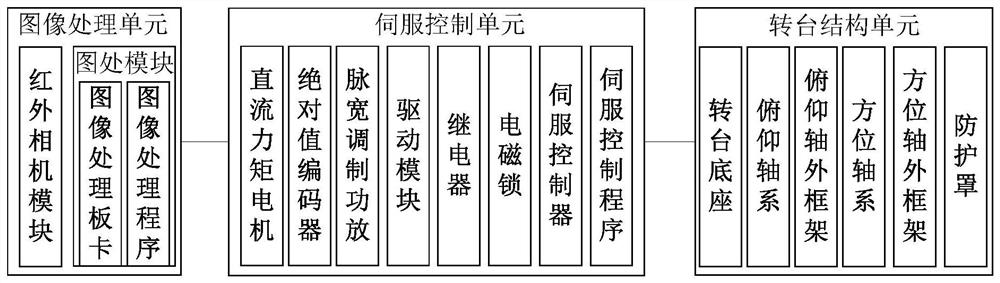

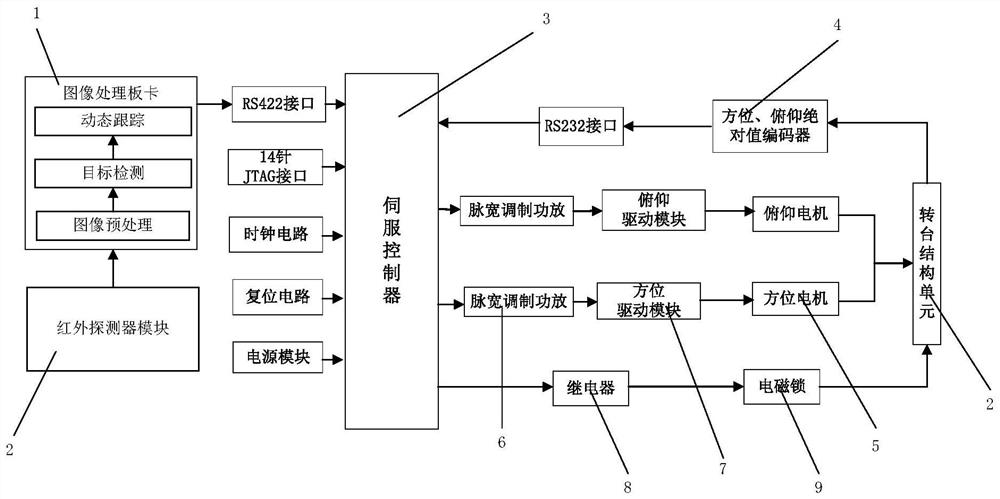

[0019] The invention provides a high-precision servo system, such as figure 2 As shown, it can be detailed as follows:

[0020] The system initialization module is executed from the power-on of the program, involving all registers, global variables, macro definitions, structures, flags, counting variables, PID parameters, motor position initial parameters, and various output data limit value settings used by the program. And peripheral clock control registers, GPIO registers, VPIF, PSC, UART for initialization configuration.

[0021] After the system initialization is completed, the system enters the interrupt service program, reads the current position of the azimuth and pitch motors sent by the absolute encoder 4, and the serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com