Process and device for treating water by fluidized bed type suspension and photocatalytic oxidization in built-in depositing separation area

A technology of photocatalytic oxidation and water treatment equipment, which is applied in the direction of separation method, precipitation separation, light water/sewage treatment, etc., can solve the problems of inconvenient operation, low proportion of ultraviolet rays, and speed limit, etc., to shorten the treatment time and increase the treatment The effect of water volume and efficient oxidation decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

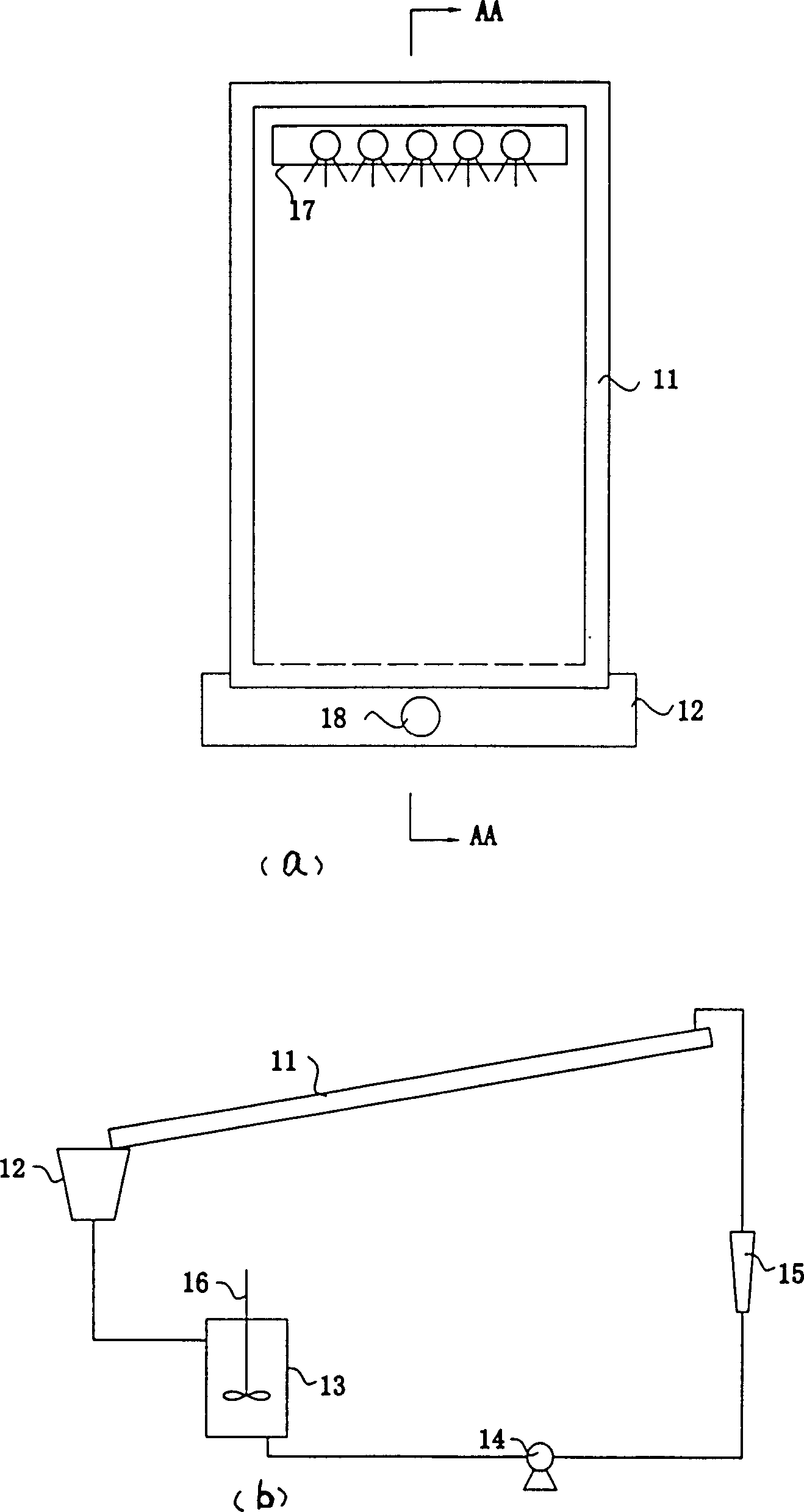

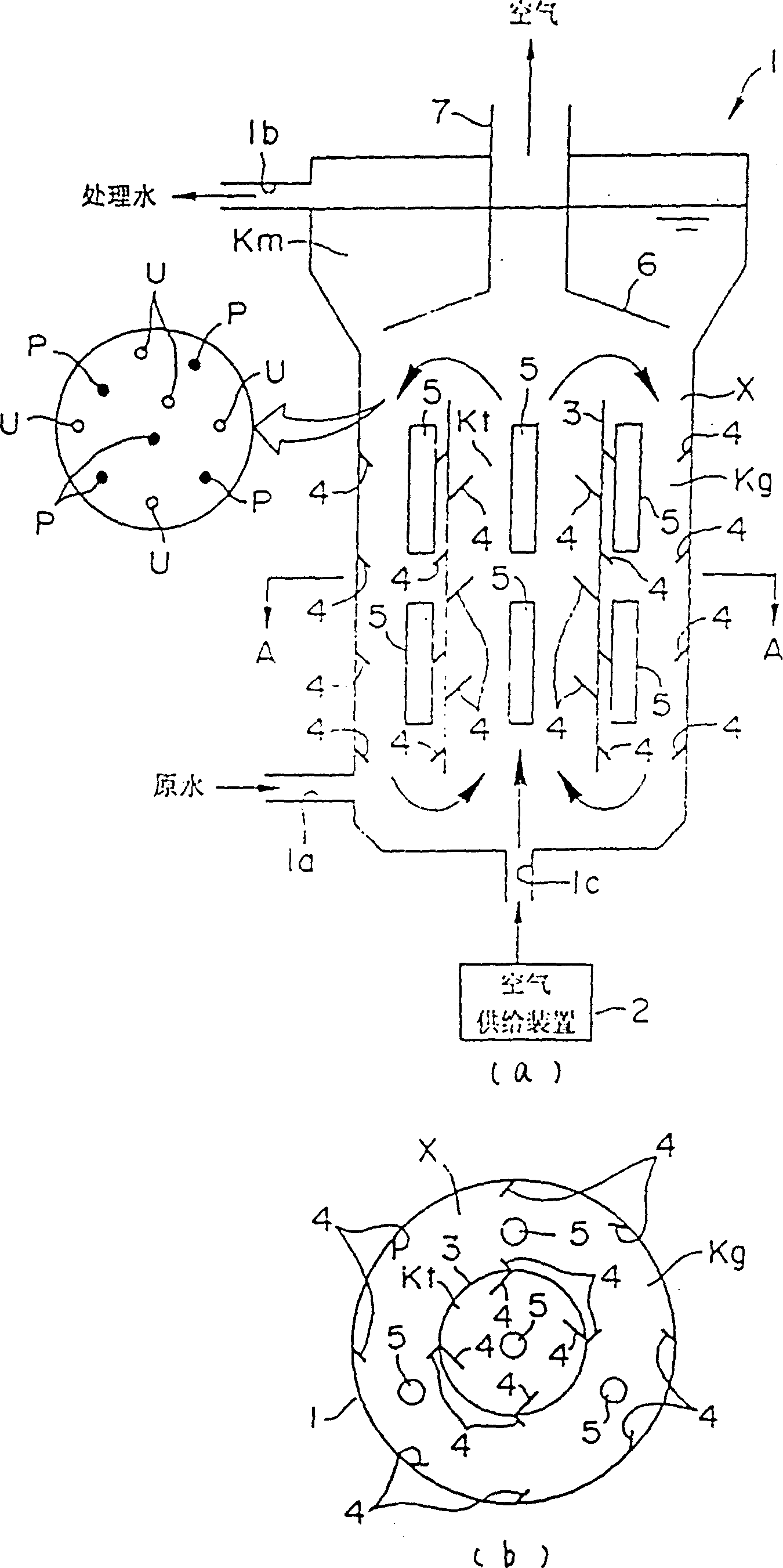

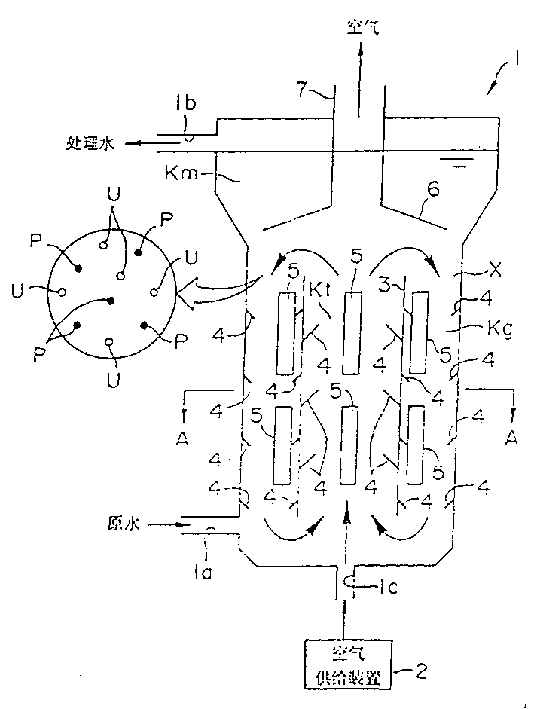

[0023] Embodiments of the photocatalytic oxidation water treatment method and device related to the present invention, combined with figure 2 The detailed description is as follows.

[0024] This embodiment is a fluidized bed type water treatment device, its structure is as follows figure 2 As shown, it includes a reactor outer shell 1, a mixed liquid X is housed in the shell, an air supply device (circulation device) 2, a deflector 3, a swirl plate (swirl device) 4, an ultraviolet lamp (excitation light source) 5, Gas outlet 7.

[0025] In the figure, the reactor shell 1 is a hollow cylindrical structure with its axis perpendicular to the horizontal plane. The lower side of the reactor shell 1 is provided with a water inlet 1a, the upper side is provided with a discharge port 1b, and the center of the bottom is provided with a water source from the air. The inlet 1c of the gas supplied to the device, a cylindrical deflector 3 is arranged in the middle of the device to div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com