Lithium battery negative electrode material with nano-silicon retained in carbon shell and its production method and use

A technology of negative electrode material and production method, which is applied to battery electrodes, lithium storage batteries, negative electrodes, etc., can solve the problems of high cost, easy agglomeration of nano-silicon, pulverization and shedding of active materials, etc., and achieves the effect of avoiding the pretreatment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

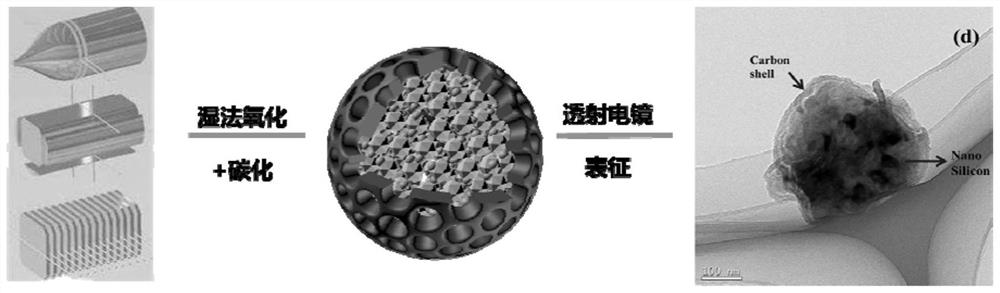

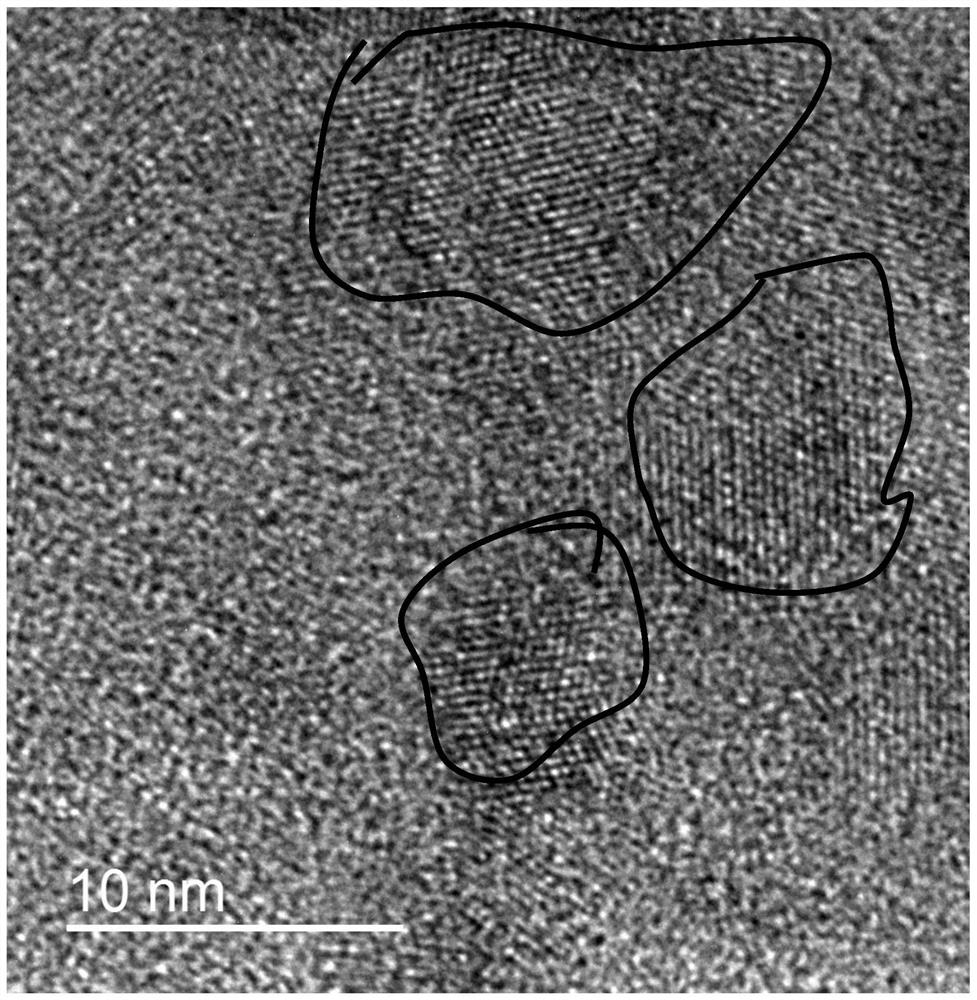

[0039] The preparation method of the lithium battery silicon carbon negative electrode material of this embodiment includes the following steps:

[0040] (1) Press filter the waste silicon powder produced during the diamond wire cutting process in the silicon wafer production process into a cake; the filter cake is composed of elemental silicon powder with a particle size of 1-3 μm, organic cooling liquid and water; according to the previous According to industry experience, the proportions of residual organic matter, water and elemental silicon micropowder in the filter cake are 5-10%, 40-50% and 50-60% respectively; the filter cake is added to water to form a solution, and the proportion of elemental silicon micropowder is 5-10%, 40-50% and 50-60% respectively. The solid content is between 10-20% to ensure that the heat in the subsequent oxidation process is absorbed by the solution, but does not overflow;

[0041] (2) Dissolving the filter cake in step (1) in water, it is e...

Embodiment 2

[0051] The only difference between this example and Example 1 is that in step (2), the solid content of the elemental silicon micropowder in the solution is 10%, and the rest are the same.

[0052] Compared with the traditional lithium battery (graphite negative electrode material, the specific capacity is 372mAh / g), the lithium battery silicon carbon packaged in the present invention adopts the constant current charge-discharge method to test the specific capacity and cycle performance of the material, and the test result is the ratio of the negative electrode material. The capacity is 1300mAh / g, which is 3 times the specific capacity of graphite anode material, and the specific capacity is stable at 1120mAh / g after 100 cycles without rapid decay.

Embodiment 3

[0054] The difference between this embodiment and Embodiment 1 is only that in step (4), the activating substance of the oxidant in the solution is cobalt nitrate, and the rest are the same.

[0055] Compared with the traditional lithium battery (graphite negative electrode material, the specific capacity is 372mAh / g), the lithium battery silicon carbon packaged in the present invention adopts the constant current charge-discharge method to test the specific capacity and cycle performance of the material, and the test result is the ratio of the negative electrode material. The capacity is 1300mAh / g, which is 3 times the specific capacity of graphite anode material, and the specific capacity is stable at 1120mAh / g after 100 cycles without rapid decay.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com