Ulna olecranon morphological anatomy locking method and steel plate structure

A technology of olecranon and steel plate of the ulna, applied in the directions of outer plate, fixator, internal bone synthesis, etc., can solve the problems of low tensile strength of the ulna, damaged joints, strong foreign body sensation, etc. Tissue stimulation with little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

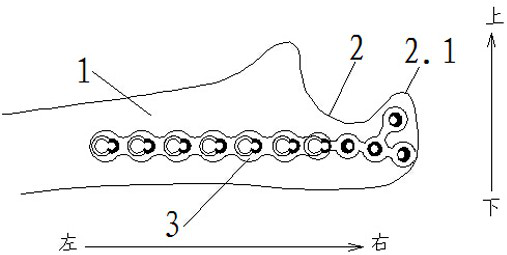

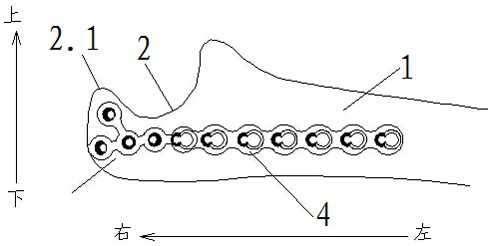

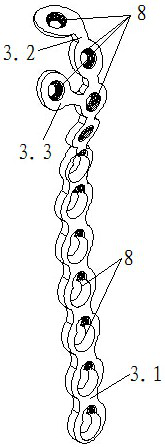

[0055] like Figure 1-4 , as shown in 11-19, an olecranon morphological anatomical locking plate structure, including locking plate I3 and locking plate II4, the locking plate I3 includes a stem I3.1 that can be attached to the front end of the ulnar body 1, and the stem I3.1 is provided with a plurality of locking holes 8, the stem I3.1 is connected with the head I that can fit with the olecranon 2, and the locking plate II4 includes the stem II4 that can fit with the rear end of the ulnar body 1 .1, the stem II 4.1 is provided with a plurality of locking holes 8, and the stem II 4.1 is connected with a head II which can fit with the olecranon 2; Fitted first head I3.2 and second head I3.3 fit to the front end of the olecranon tip 2.1, said head II includes the first head II4 fit to the right end of the olecranon 2 .2 and the second head II 4.3 that can be attached to the rear end of the olecranon tip 2.1; the first head I 3.2 is provided with at least one locking hole 8, th...

Embodiment 2

[0071] like Figure 5-6 As shown, the difference between this embodiment and Embodiment 1 is that the locking hole 8 includes half a tapered threaded hole and half a tapered light hole connected to each other.

Embodiment 3

[0073] like Figure 7-10 As shown, the difference between this embodiment and Embodiment 1-2 is: an anatomical locking plate structure of the olecranon shape, including locking plate I3 and locking plate II4, the locking plate I3 includes a front end that can be connected to the ulnar body 1 Fitted cadre I 3.1, the cadre I 3.1 is provided with a plurality of locking holes 8, the cadre I 3.1 is connected with the head I that can fit with the olecranon 2, and the locking steel plate II 4 includes a The cadre II 4.1 attached to the rear end of the ulnar body 1, the cadre II 4.2 is provided with a plurality of locking holes 8, and the cadre II 4.2 is connected with the head II that can be attached to the olecranon 2; The head I includes a second head I3.3 that can be attached to the front end of the olecranon tip 2.1, and the head II includes a first head II4.2 that can be attached to the right end of the olecranon 2 and can be attached to the front end of the olecranon 2. The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com