Tire inner tube anti-adhesion treatment device and method

A processing device and anti-adhesion technology, which is applied in the direction of spraying devices, liquid spraying devices, and devices for coating liquid on the surface, etc., which can solve the problem of limited coverage and overlapping range of nozzles or nozzles, difficulty in uniform spacer fluid, and easy fall off of inner tube tubes and other issues to achieve the effect of reducing product defects, reducing product defects, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

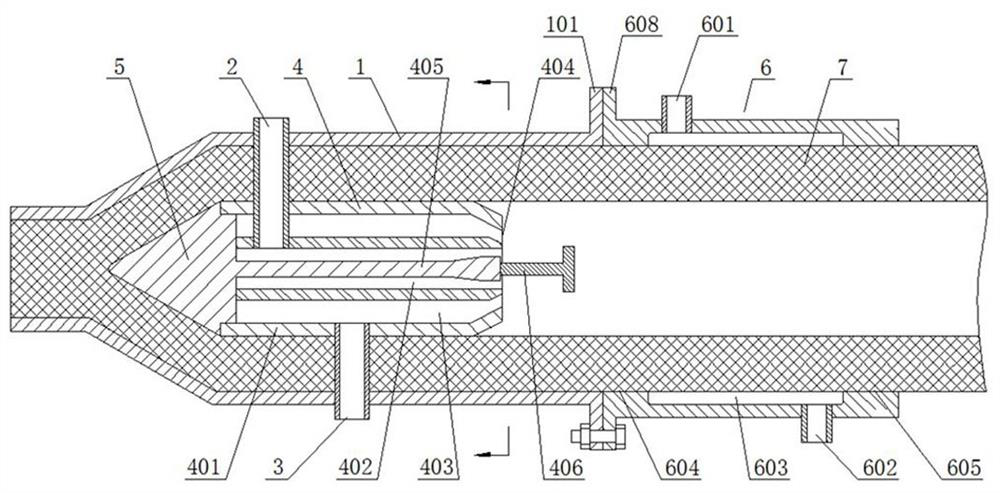

[0039] Such as figure 1 , 2 As shown in and 3, the tire inner tube anti-blocking treatment process is as follows:

[0040] S100: Mix water and inner tube spacer at a ratio of 40kg:2kg to obtain an inner spacer.

[0041] S200: Put the inner spacer liquid into the stirring container and mix thoroughly, then keep the pressure in the stirring container at 6kgf / cm 2 and continue stirring.

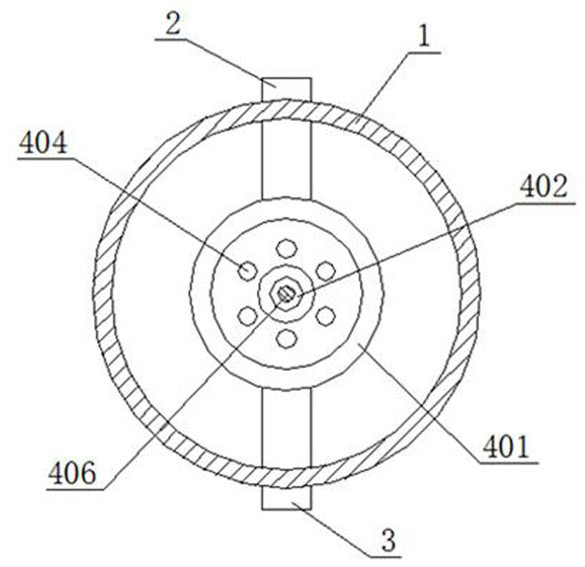

[0042] S300: Pass the inner spacer liquid in the mixing container into the liquid inlet pipe 3 of the tire inner tube anti-adhesion treatment device, and feed 7kgf / cm into the air inlet pipe 2 at the same time 2 The high-pressure air, the inner spacer liquid passes through the multiple injection holes II 404 evenly distributed around the injection hole I 402 on the buffer tank 403, mixes with the high-pressure air ejected from the injection hole I 402, and then reflects to the inner wall of the inner tube through the mixing plate 406, at this time Start the inner tube extrusion device, the r...

Embodiment 2

[0048] Such as figure 1 , 2 As shown in and 3, the tire inner tube anti-blocking treatment process is as follows:

[0049] S100: Mix water and inner tube spacer at a ratio of 40kg:3kg to obtain an inner tube spacer.

[0050] S200: Put the inner spacer liquid into the stirring container and mix thoroughly, then keep the pressure in the stirring container at 4kgf / cm 2 and continue stirring.

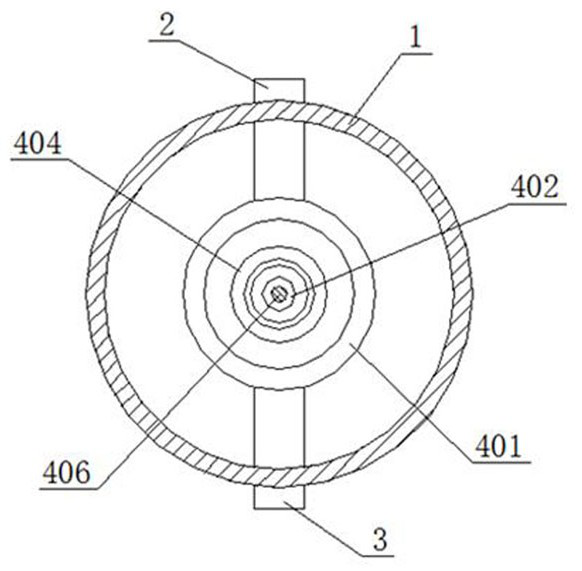

[0051] S300: Pass the inner spacer in the mixing container into the liquid inlet pipe 3 of the tire inner tube anti-adhesion treatment device, and feed 5kgf / cm into the air inlet pipe 2 at the same time 2 The inner spacer liquid passes through the annular gap-shaped injection hole II 404 around the outlet end of the injection hole I402 on the buffer tank 403, so that the inner spacer liquid passes through the injection hole II404 and mixes with the high-pressure air ejected from the injection hole I402, and then passes through the mixing plate 406 is reflected to the inner wall of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com