Multi-stage rice screening equipment and screening method

A technology for screening equipment and rice, which is applied to chemical instruments and methods, cleaning methods and appliances, filter screens, etc., can solve problems such as low work efficiency, high labor intensity, and a large amount of dust, so as to improve screening efficiency and quality, and avoid The effect of cleaning the screen and preventing the clogging of the screen holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

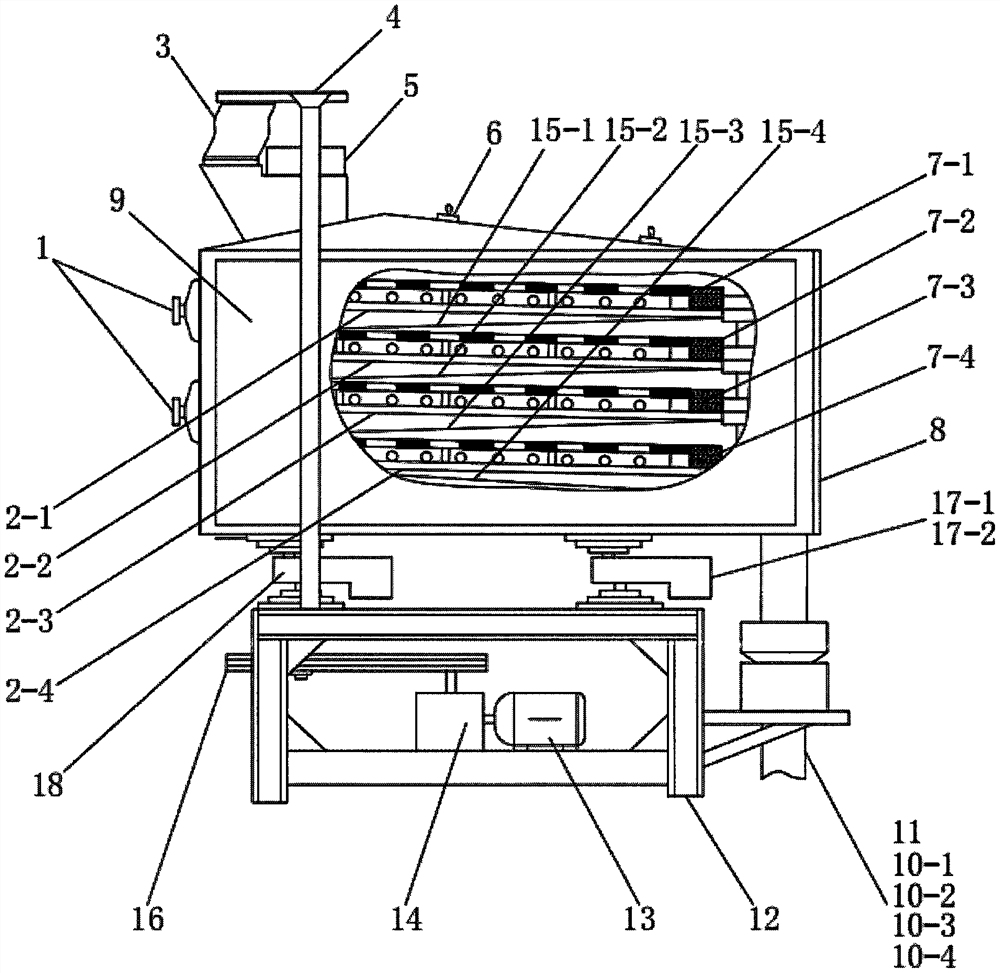

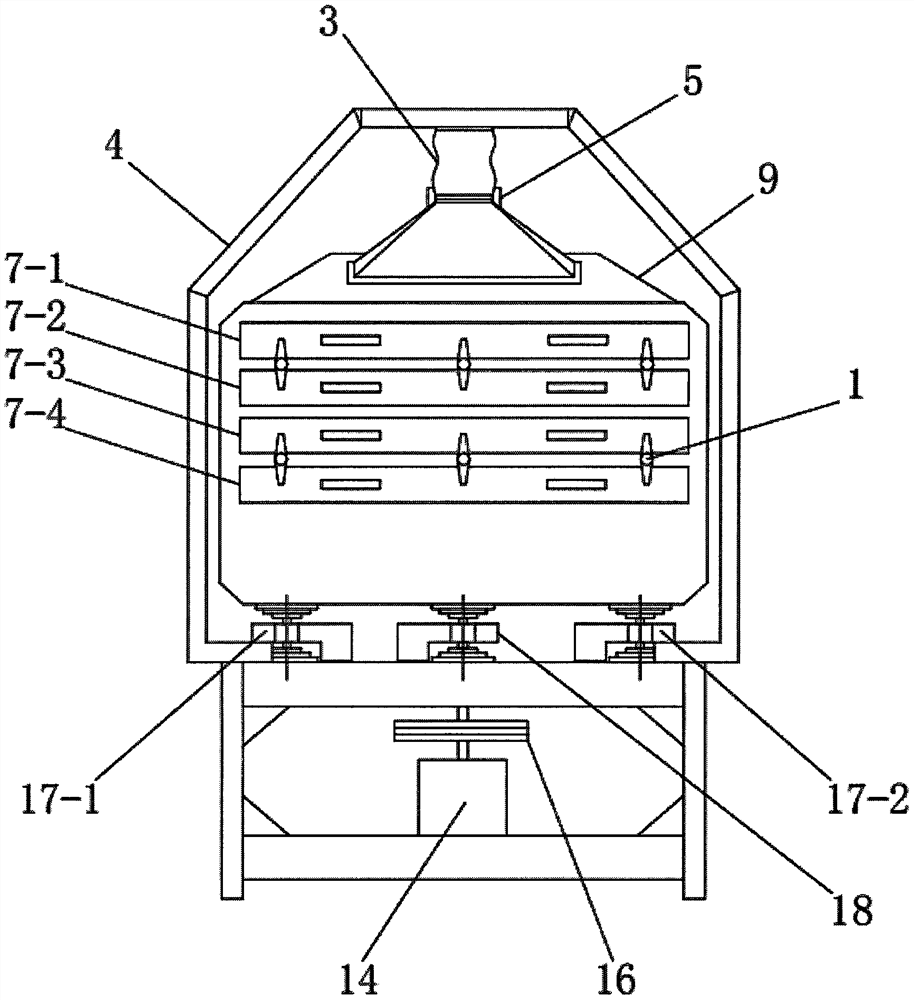

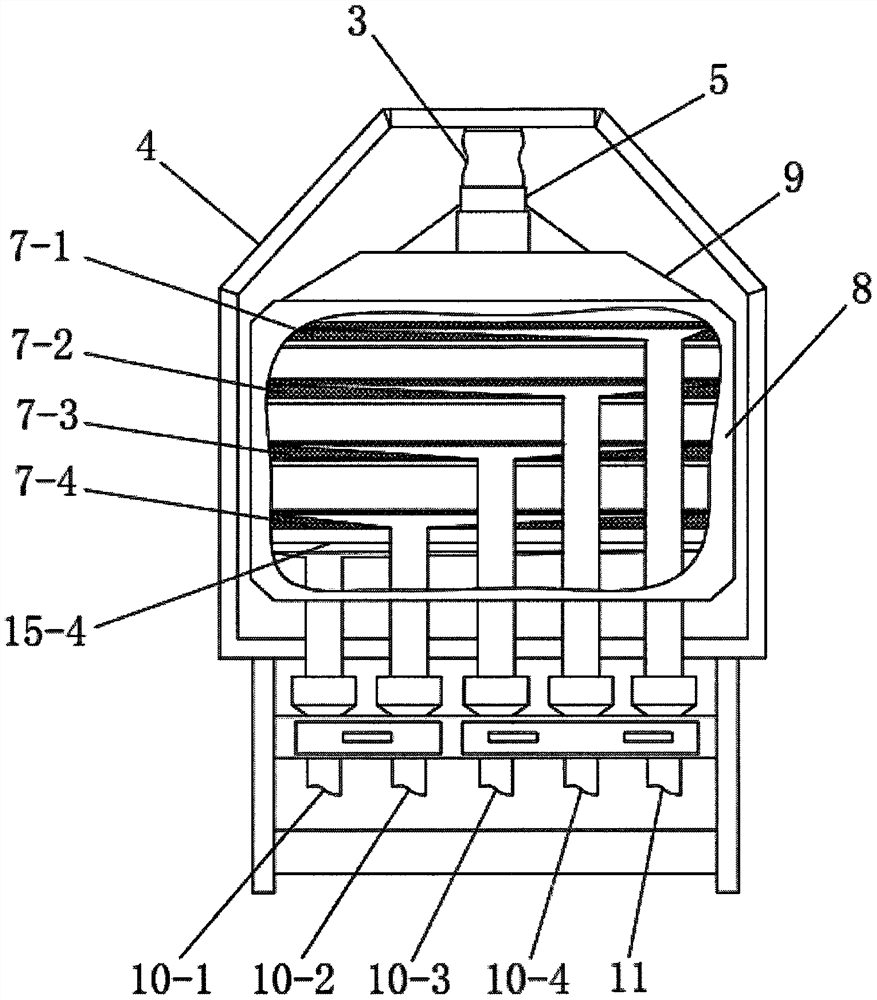

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] The present invention provides a rice multi-stage screening device, which includes a connected power transmission device and a material screening device. The power transmission device includes a main body frame 12, an eccentric rotary mechanism and a connecting bracket that are rotatably arranged on the main body frame 12 4. A motor 13 and a gearbox 14 are also arranged on the main body frame 12, and the motor 13 is connected to the gearbox 14; the material screening device includes a vibrating bin 9, a separating screen and a rice discharge pipe, and the separating screen is movable and installed on the vibrating In the bin 9, the central axis of the separation screen and the central axis of the vibrating bin 9 are on the same straight line; the vibrating bin 9 and the main frame 12 are connected by an eccentric rotary mechanism;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com