Bottle overturning mechanical arm of bottle washing machine

A technology of manipulators and bottle washing machines, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve problems such as damage and damage to glass bottles, achieve the effects of improving precision, preventing weak clamping, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

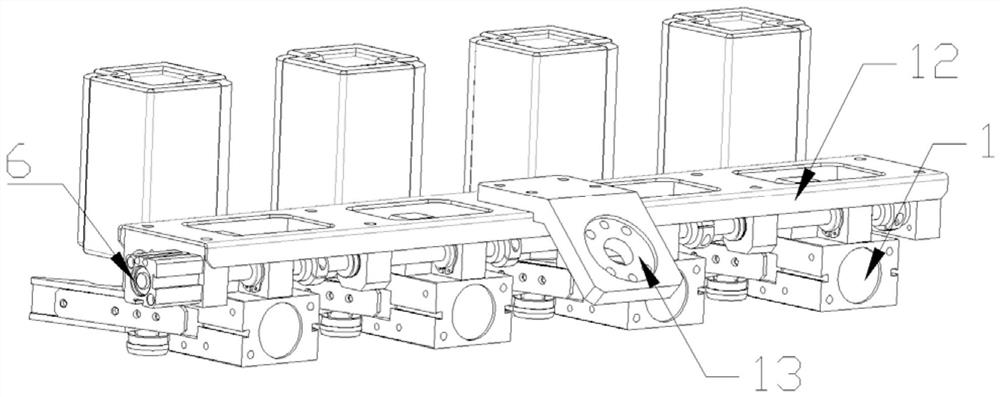

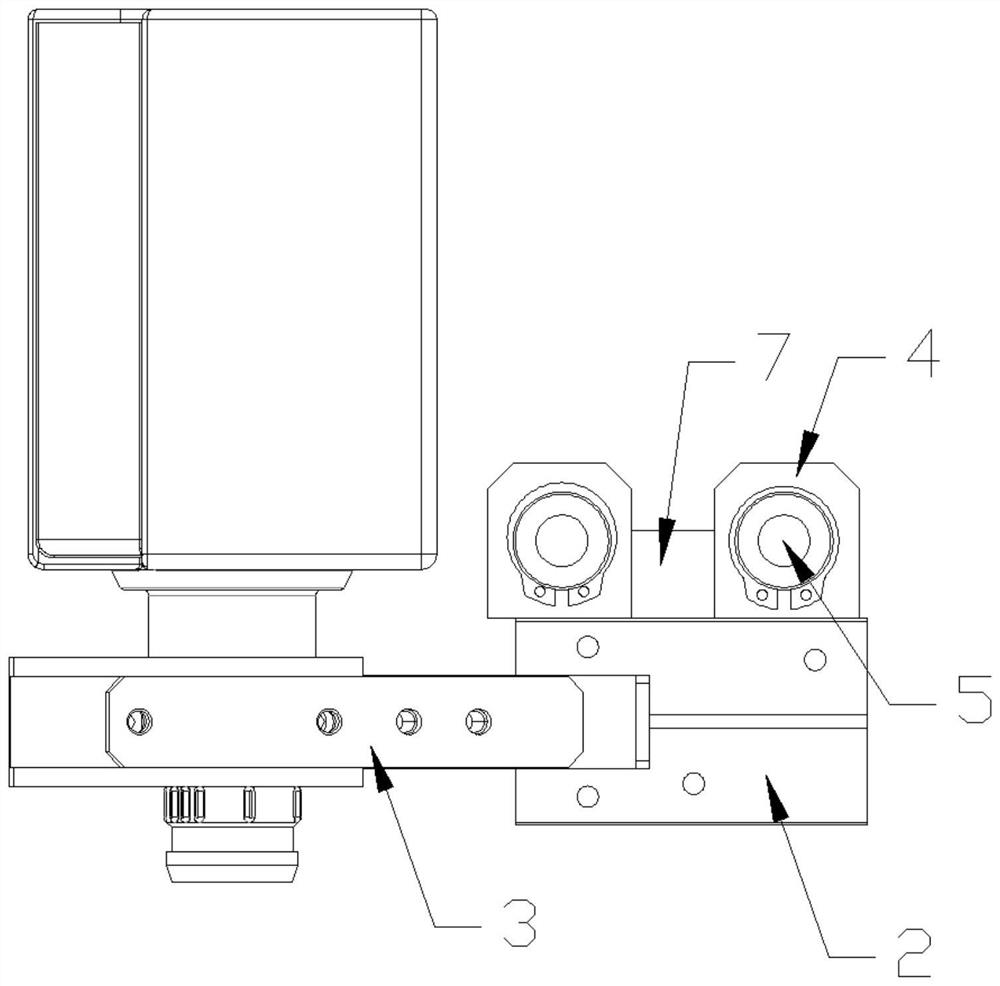

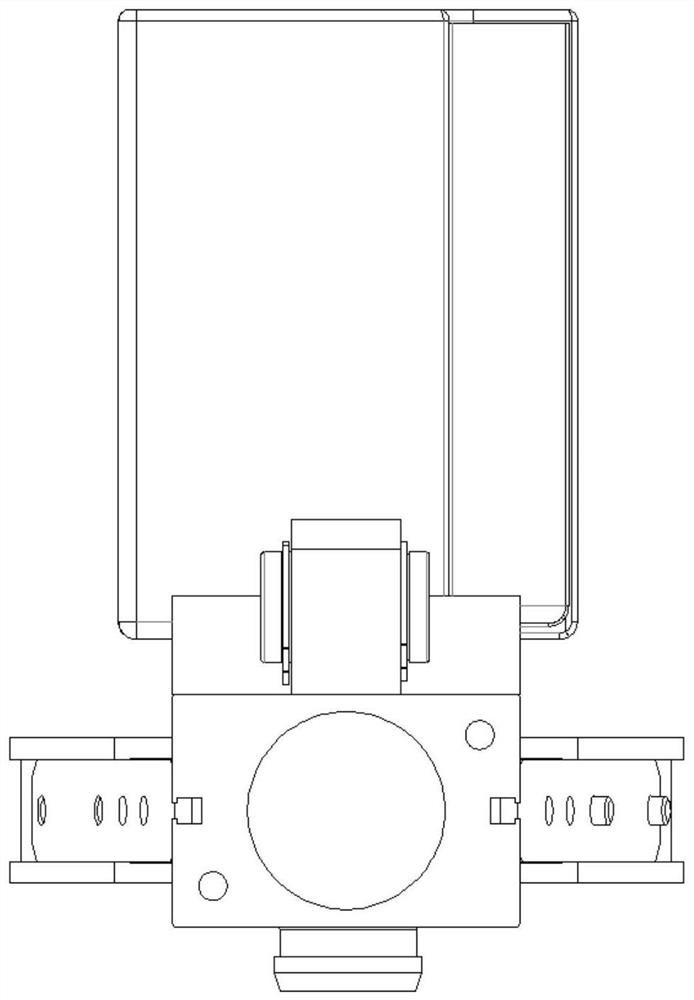

[0023] A bottle-turning manipulator of a bottle washing machine is characterized in that it includes a grabbing mechanism 1, and the grabbing mechanism 1 includes a clamping cylinder 2 connected with a mechanical claw 3, and the mechanical claw 3 is composed of two pieces connected in a V shape. The splint is composed of a bearing sleeve 4 installed above the clamping cylinder 2, a positioning shaft 5 arranged horizontally is installed in the bearing sleeve 4, and a locking cylinder 6 is connected to the end of the positioning shaft 5.

Embodiment 2

[0025] On the basis of Embodiment 1, the bearing sleeve 4 is connected with a positioning sliding block 7 , and the positioning sliding block 7 is installed on the clamping cylinder 2 . Preferably, the grasped sides of the positioning sliding block 7 can be fitted with grasping blocks that cooperate with the mechanical claws 3 for convenient clamping.

Embodiment 3

[0027] On the basis of Embodiment 1, the mechanical claw 3 is connected with a lifting device 8, and the lifting device 8 includes a supporting shaft 9 connected with the mechanical claw 3, the upper end of the supporting shaft 9 is connected with a lifting cylinder 10, and the lower end of the supporting shaft 9 is connected with a conveying Chain 11. When the mechanical claw 3 performs the grabbing action, the bottom end of the support shaft 9 cooperates with the conveying chain 11 to fix the position of the conveying chain 11 so that it does not shift, ensuring that the positioned mechanical claw 3 will not deviate from the position of the glass bottle. shift.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com