Heat transfer printing method and equipment for fiber texture network sandwich

A thermal transfer, texture technology, applied in transfer printing, rotary printing machine, copy/marking method, etc., can solve problems such as the size deformation of the printed fiber texture network sandwich

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

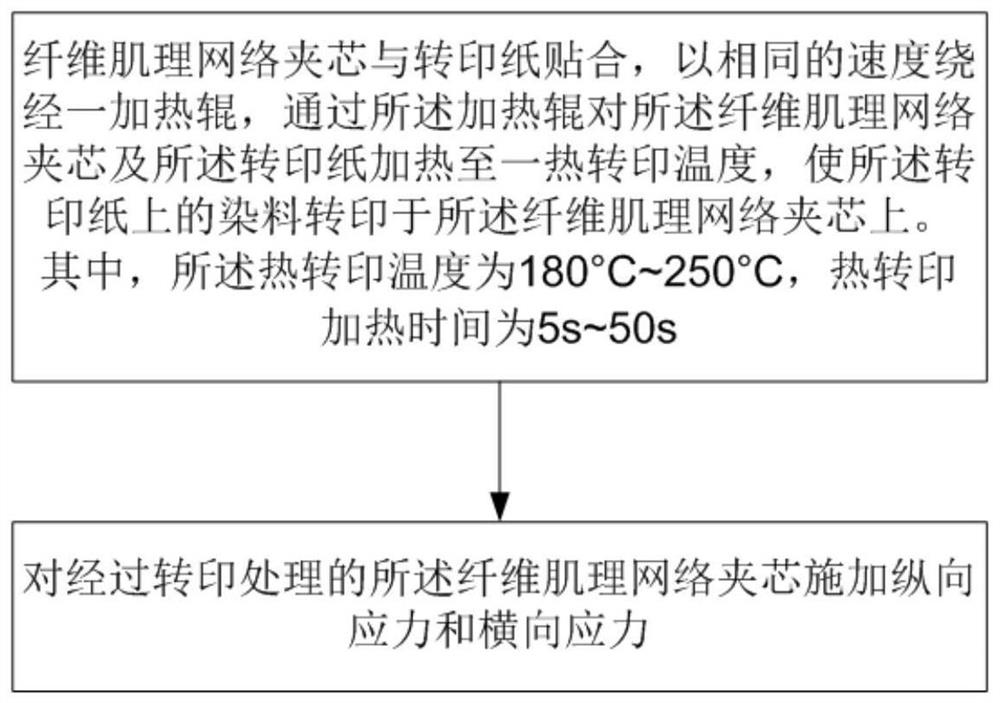

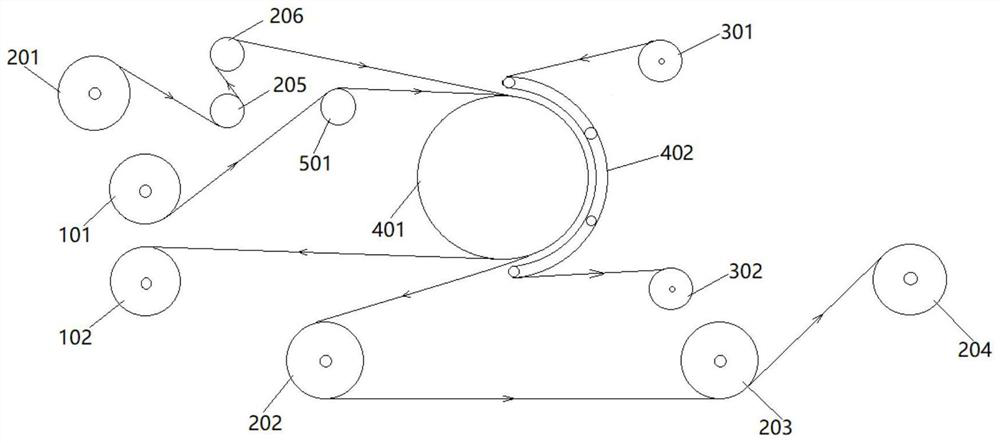

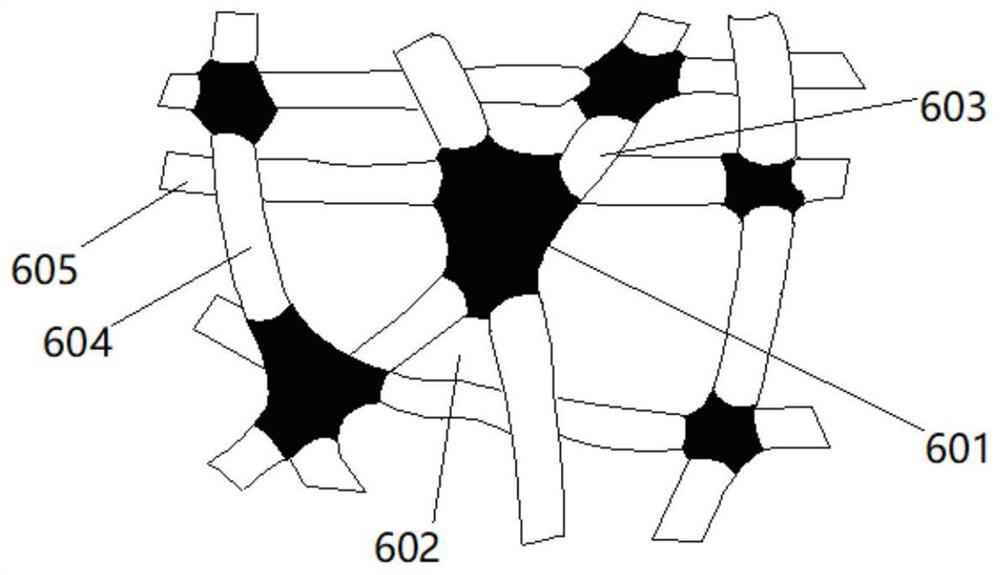

[0088] Such as figure 1 Shown, a kind of thermal transfer printing method of fiber texture network sandwich, comprising:

[0089] The fiber texture network sandwich is bonded to the transfer paper, and a heating roller is passed around at the same speed, and the fiber texture network sandwich and the transfer paper are heated to a heat transfer temperature by the heating roller, so that The dye on the transfer paper is transferred onto the fiber texture network core; longitudinal stress and transverse stress are applied to the transferred fiber texture network core. Wherein, the thermal transfer temperature is 180° C. to 250° C., preferably 210° C. to 230° C.; the thermal transfer heating time is 5 s to 50 s, preferably 10 s to 30 s.

[0090] In the present invention, the application time of the longitudinal stress and the transverse stress may be greater than, equal to, or less than the shrinkage deformation time of the fiber texture network sandwich caused by thermal transf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com