Hydraulic magneto-rheological composite brake structure for vehicle

A magneto-rheological and brake technology, which is applied in the direction of liquid resistance brakes, brakes, brake components, etc., can solve the problems of insufficient braking force of hydraulic magnetic fluid brakes, and achieve the effect of easy installation and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

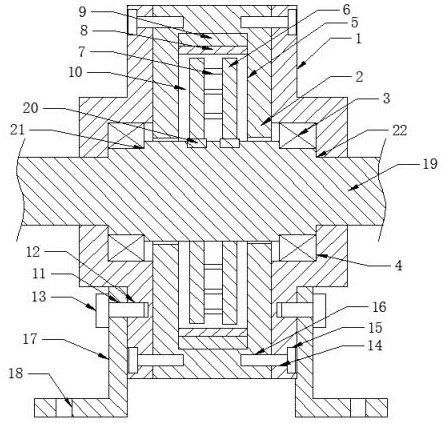

[0022] see figure 1 , the present invention provides a technical solution: a vehicle hydraulic magneto-rheological composite brake structure, including a housing 1, the middle part of the housing 1 is provided with a hole for the main shaft 19 to pass through, the number of the housing 1 is two, The positions of the two housings 1 correspond to the left and right, and the middle part of the housing 1 is provided with a bearing hole 4, and a bearing 3 is installed in the bearing hole 4, and a main shaft 19 is installed between the bearings 3 on the left and right sides, The middle part of the main shaft 19 is equipped with a brake shell 2, and the brake shell 2 is located between the shells 1 on the left and right sides. The cross sections of the shell 1 and the brake shell 2 are circular, and the shell 1 and the brake shell The maximum outer diameter of the shell 2 is equal, the outer edge of the housing 1 is provided with a countersunk hole 15, the outer edge of the brake hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com