Environment-friendly garbage treatment equipment

A waste treatment equipment and environmental protection technology, applied in the direction of organic fertilizers, climate change adaptation, etc., can solve the problems of increased scale, long treatment cycle, limited treatment capacity, and few research results, so as to increase the chance of flushing contact and improve the gas efficiency. Purification effect, the effect of increasing the length of the moving path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

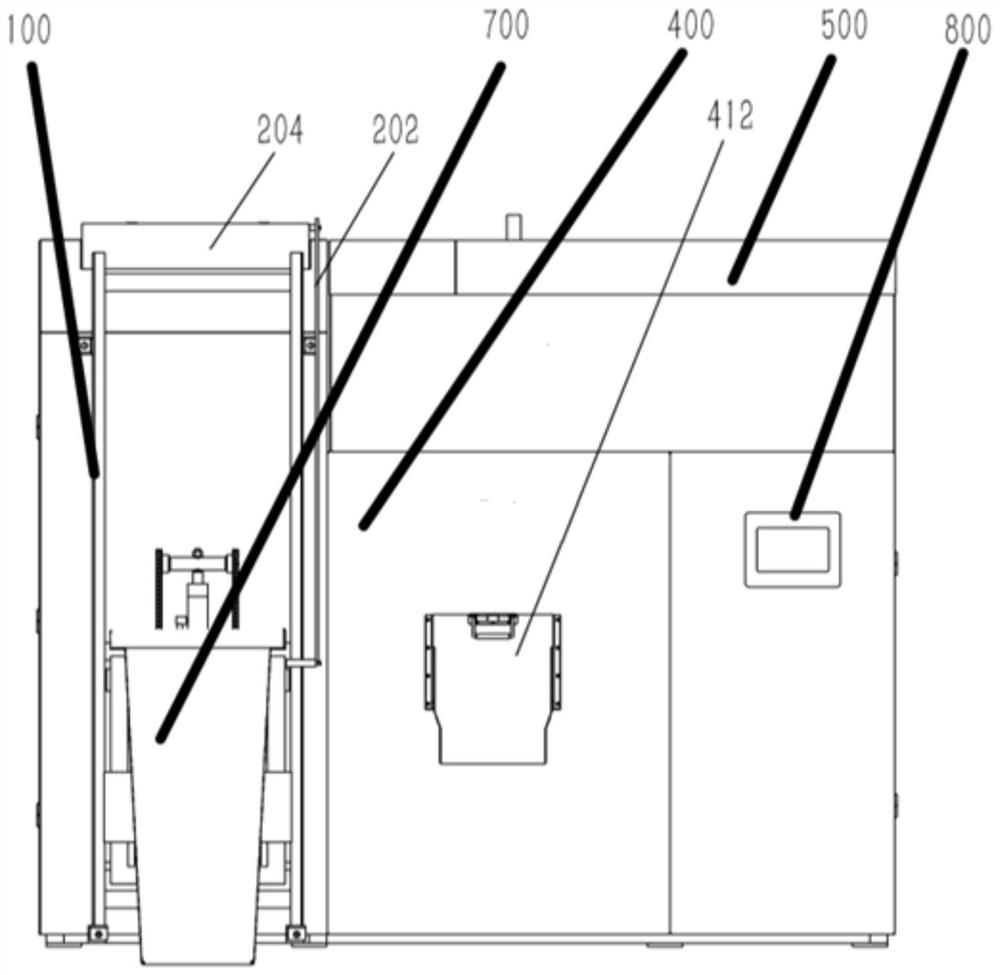

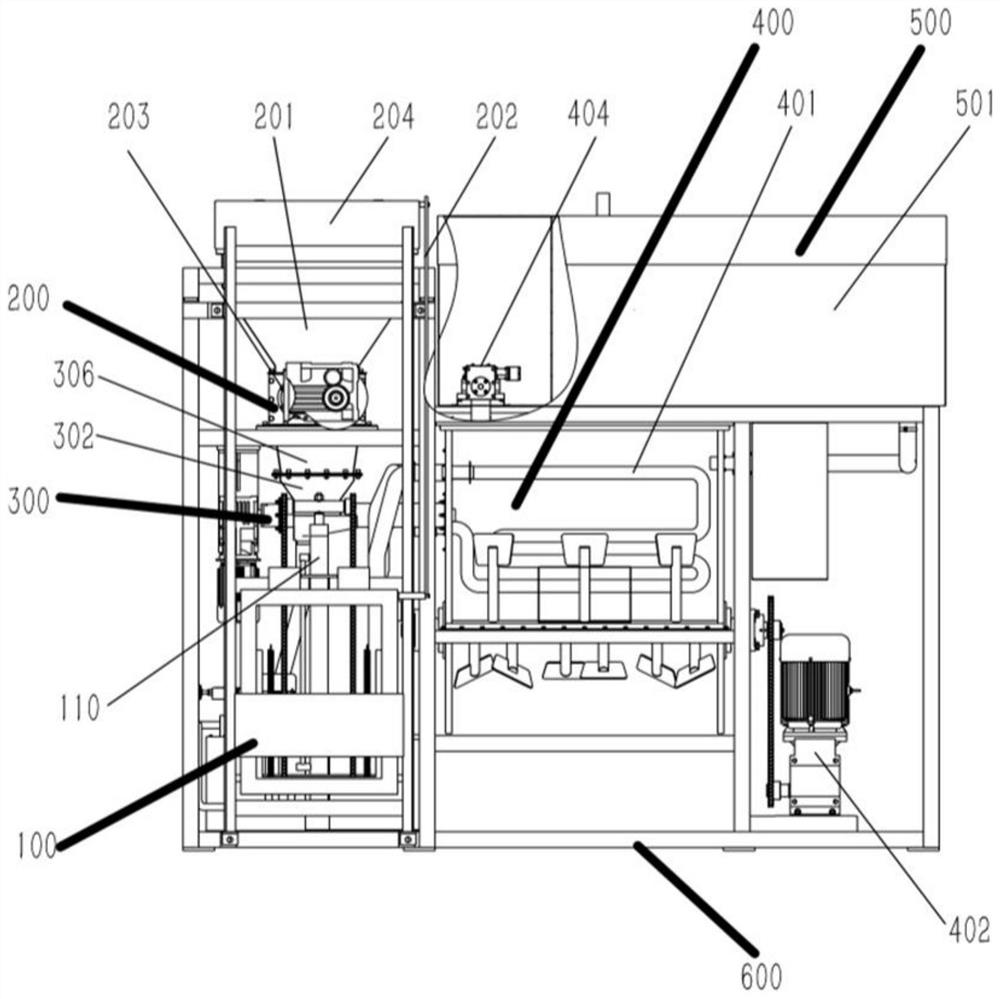

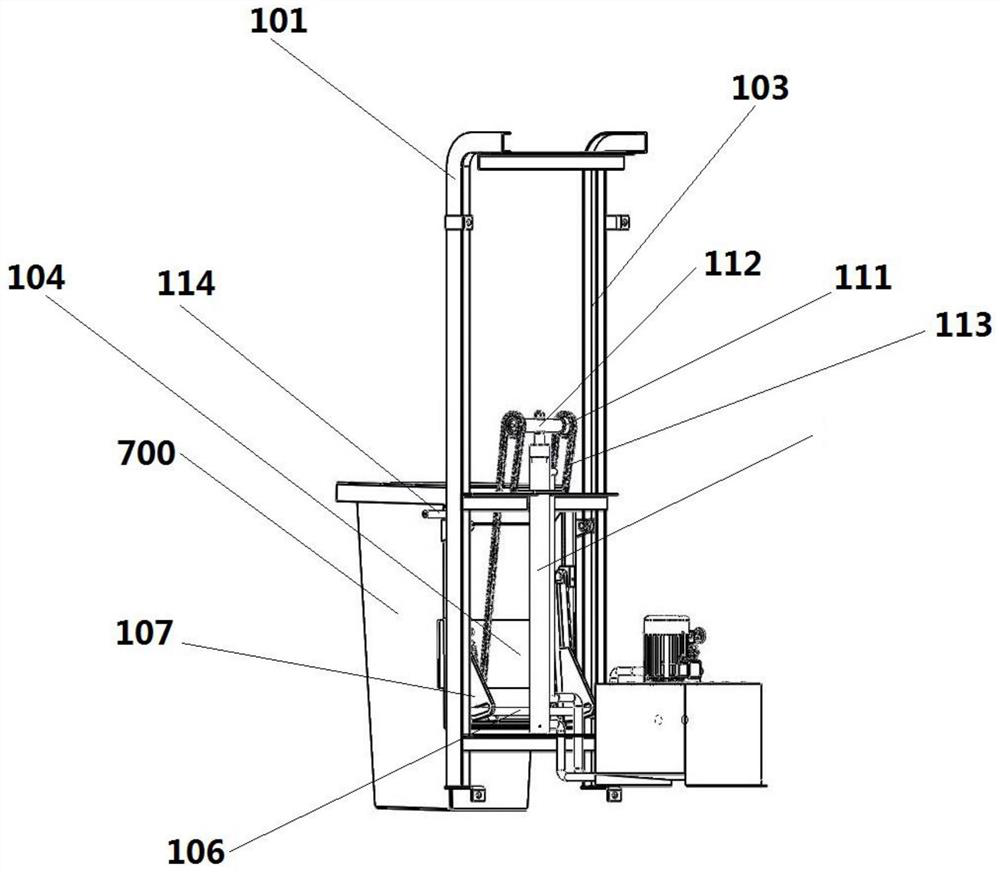

[0037] Such as Figure 1-11 As shown, the present invention specifically discloses a kind of environmental protection garbage processing equipment, including a standard garbage container 700, a feeding mechanism 100, a crushing mechanism 200, a dehydration mechanism 300, a biochemical mechanism 400, a purification mechanism 500 and a frame 600, and the feeding mechanism 100 , the crushing mechanism 200, the dehydration mechanism 300 and the biochemical mechanism 400 are all fixed on the frame 600, and the purification mechanism 500 is fixed on the top of the frame 600;

[0038] The standard garbage container 700 is arranged on the feeding mechanism 100, and the feeding mechanism 100 is arranged on one side of the crushing mechanism 200, and the bottom of the crushing mechanism 200 is provided with a dehydration mechanism 300, and one side of the dehydration mechanism 300 is connected with the biochemical mechanism 400, and the biochemical mechanism 400 is connected with the pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com