Sheep manure composting method

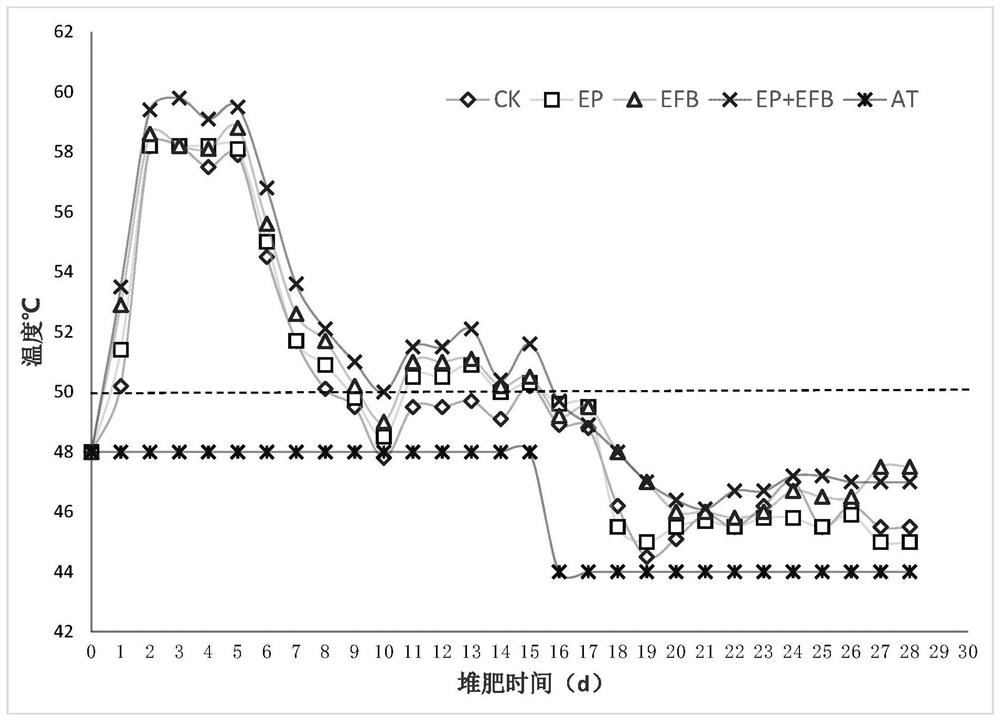

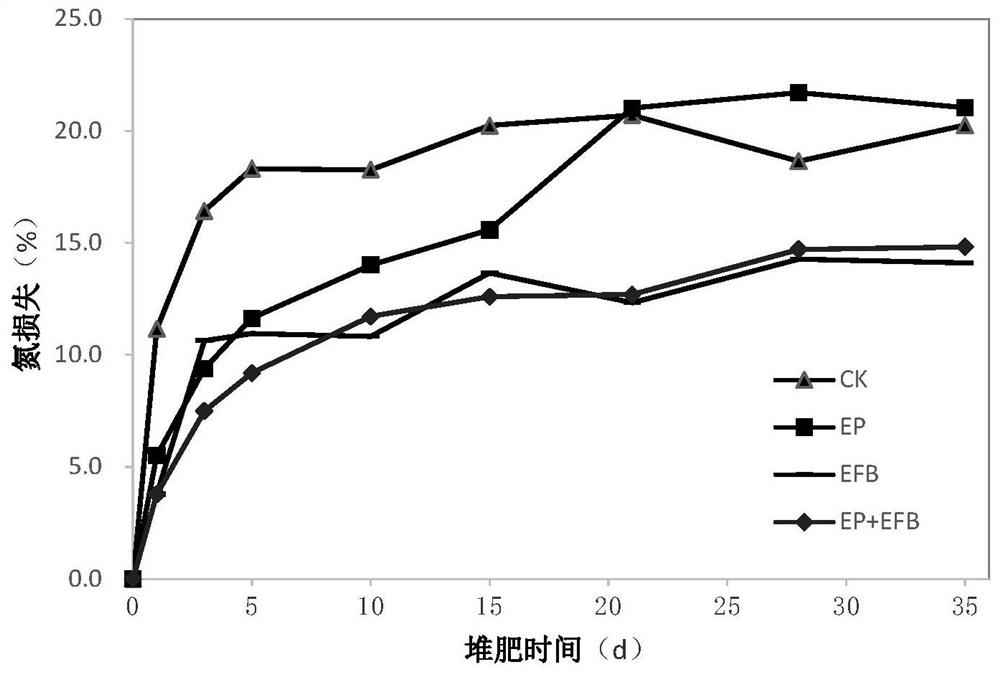

A sheep manure and composting technology, applied in the agricultural field, can solve problems such as high cost and environmental damage, and achieve the effects of prolonging the high temperature period, promoting the decomposing of nitrogen fertilizer and reducing nitrogen loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

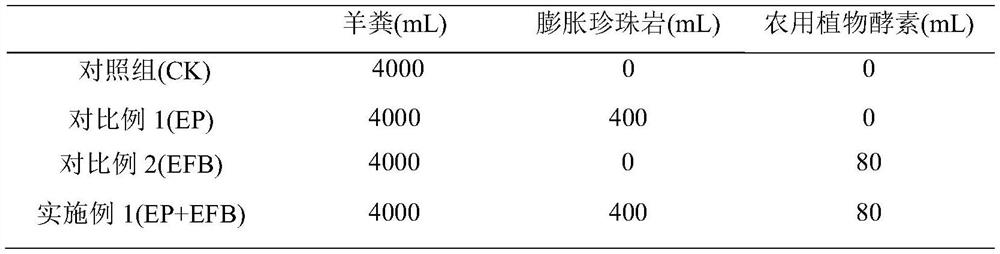

Embodiment 1

[0031] Example 1 A method for composting sheep manure, comprising the steps of:

[0032] (1) The sheep manure is air-dried to remove impurities, and then 2% and 10% of EFB and EP are added by volume fraction respectively to the sheep manure (the fine powder particles are removed by sieving with a 2mm sieve) to obtain a mixture;

[0033] (2) Adjust the moisture content of the above mixture to 60-70wt% and start composting, measure the temperature every day, when the temperature of the pile is higher than 50°C, turn the pile once every 2 days, when the temperature of the pile is 40-50°C , Turn the pile every 3 days; when the temperature of the pile body is lower than 40°C, turn the pile every 7 days. When the temperature of the heap is 20-30°C, the composting is completed.

[0034] Among them, the agricultural plant enzyme is obtained by mixing jujube, sugar, and water in a mass ratio of 3:1:10, and fermenting at a constant temperature of 30°C for 90 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com