Nylon or polyester covering spandex method for yarn-dyed, knitted, piece-dyed fabrics

A technology of nylon and polyester, applied in the direction of textiles, papermaking, yarn, etc., to achieve uniform density, reduce cloth surface defects, improve weaving efficiency and cloth surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

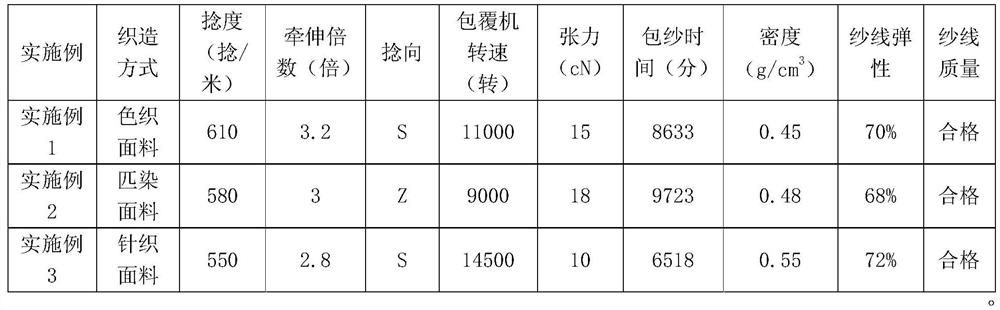

Embodiment 1

[0018] Example 1: Yarn-dyed fabric covering process: 40D nylon + 20D spandex, twist: 610 twists / m, covering draft ratio: 3.2 times, covering yarn twist direction: S twist

[0019] Stainless steel aluminum tube is used. The surface of the aluminum tube is smooth and free of scratches. Tension-controlled winding machine is used. The weight of the covered yarn is 0.8KG / piece. , the coating machine is a computer-controlled coating machine, and the specific operation steps are as follows:

[0020] (1) Yarn pouring: pour the nylon raw yarn into the aluminum tube for the coating machine, the speed is 800m / min, the raw yarn and the aluminum tube yarn have the same center line, and the spandex denier is 20D;

[0021] (2) Parameter setting: carry out the spandex yarn, the aluminum tube yarn, and the paper tube in sequence, the transmission ratio of the drafting gear: 1345.996 / 610=2.2065, the transmission ratio of the feeding gear: 3768.789 / 610 / 3.2=1.9307, Transmission ratio of crimping...

Embodiment 2

[0024] Example 2: Piece-dyed fabric covering process: Nylon covering spandex method in piece-dyeing field

[0025] Covering twist: 50D polyester + 20D spandex, 580 twists / meter, covering draft: 3 times, covering yarn twist direction: Z twist

[0026] Stainless steel aluminum tube is used. The surface of the aluminum tube is smooth and free from scratches. Tension-controlled winding machine is used. The weight range of the covered yarn is 0.95KG / piece. The covered paper tube is made of parallel paper with smooth surface, no burrs and grooves The coating machine is a computer-controlled coating machine, and the specific operation steps are as follows:

[0027] (1) Yarn pouring: pour the polyester raw yarn into the aluminum tube for the coating machine, the speed is 900m / min, the raw yarn and the aluminum tube yarn have the same center line, and the spandex denier is 20D;

[0028] (2) Parameter setting: carry out the spandex swing yarn, aluminum tube swing yarn, install the pape...

Embodiment 3

[0031] Example 3: Knitted fabric covering process: nylon covering spandex method in the field of knitting

[0032] Covering twist: 40D nylon + 20D spandex, 550 twists / meter, covering draft: 2.8 times, covering yarn twist direction: S twist

[0033] Stainless steel aluminum tube is used. The surface of the aluminum tube is smooth and free of scratches. Tension-controlled winding machine is used. The weight range of the covered yarn is 0.9KG / piece. The coated paper tube is made of parallel paper with smooth surface, no burrs and grooves. The coating machine is a computer-controlled coating machine, and the specific operation steps are as follows:

[0034] (1) Yarn pouring: pour the nylon or polyester raw yarn into the aluminum tube for the coating machine, the speed is 1100m / min, the raw yarn and the aluminum tube yarn have the same center line, and the spandex denier is 20D;

[0035](2) Parameter setting: carry out the spandex yarn, the aluminum tube yarn, and the paper tube i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com