Installed and welded type large-caliber steel lamp post

A large-diameter, steel technology, which is applied in the field of large-diameter steel lamp poles of assembled welding type, can solve the problems of poor force on the slide rail, cannot be completed, and the internal structure is complicated, so as to improve the force-bearing performance, reduce the difficulty of forming, Simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

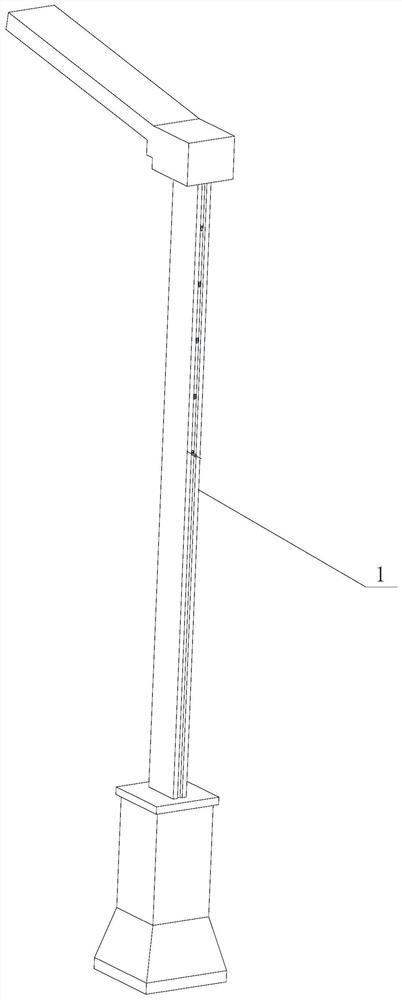

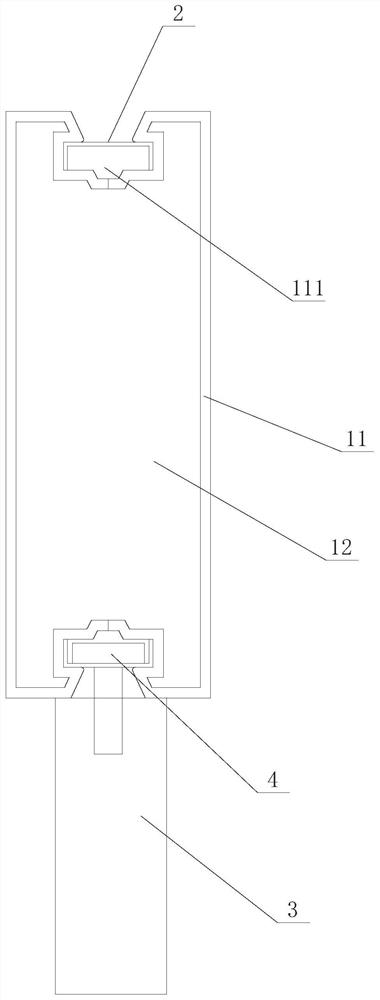

[0035] Figure 1 to Figure 3 It shows the first embodiment of the large-diameter steel light pole of the assembly welding type of the present invention, the large-diameter steel light pole includes a steel rod 1 and a damping member 2, and the steel rod 1 includes at least two steel rods Opening profiles 11, each steel opening profile 11 is enclosed and spliced to form a steel rod 1, and the steel rod 1 has a large opening 12, at least one steel opening profile 11 is bent and formed with a functional groove 111, the surrounding The joint joint is arranged in the functional groove 111, and each steel opening profile 11 is welded and connected to the enclosed joint. The damping part 2 is sealed in the functional groove 111 and covers the weld seam. The damping part 2 is provided with a connection for connecting the functional part 3. piece 4. The light pole involves a large diameter and is formed by steel profiles, that is, at least two steel opening profiles 11 are used to b...

Embodiment 2

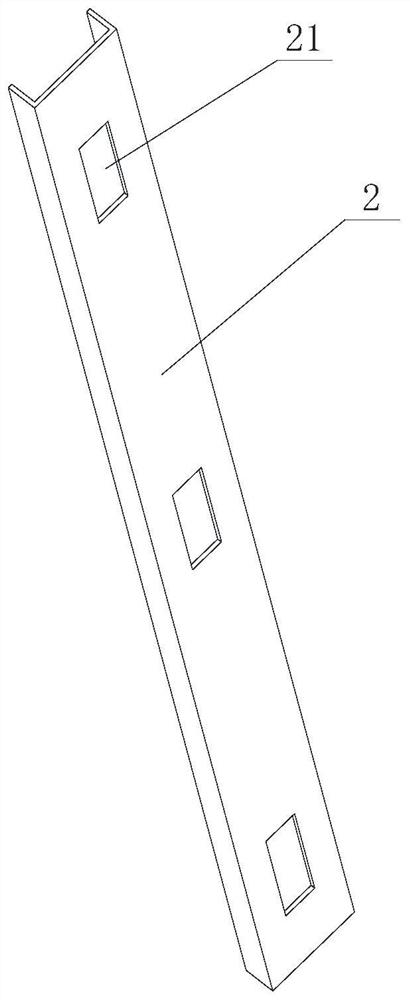

[0042] Figure 4 to Figure 6It shows the second embodiment of the large-diameter steel light pole of the assembled welding type according to the present invention. The large-diameter steel light pole is basically the same as that of Embodiment 1, and the only difference is that in this embodiment, the installation position 21 includes an edge damping The insertion groove 211 provided by the part 2 and the bracket 212 arranged at intervals on the insertion groove 211, the T-shaped bolts extend from the insertion groove 211, and reverse the notch of the functional groove 111 after the rotation angle, T-shaped The bolts are carried on pallets 212 . In this structure, the T-shaped bolts extend from the insertion slot 211 into the notch of the reverse buckle function groove 111 after the rotation angle, and further the T-shaped bolts are carried on the support platform 212 to provide support for it. The structure is simple and ingenious.

Embodiment 3

[0044] Figure 7 to Figure 8 It shows the third embodiment of the large-diameter steel light pole of the assembled welding type according to the present invention. The large-diameter steel light pole is basically the same as that of Embodiment 2, and the only difference is that in this embodiment, the installation position 21 includes an edge damping The insertion groove 211 provided by the part 2 and the shrapnel 213 arranged on both sides of the insertion groove 211, the T-bolt extends from the insertion groove 211 and squeezes the shrapnel 213, after the rotation angle, the T-bolt buckles the two sides. Shrapnel 213. In this structure, the T-bolt squeezes and buckles the shrapnel 213 on both sides, which greatly improves the fastening strength.

[0045] In this embodiment, each steel opening profile 11 is enclosed and welded to form a triangle. The triangular steel rod 1 has a simple and reliable structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com