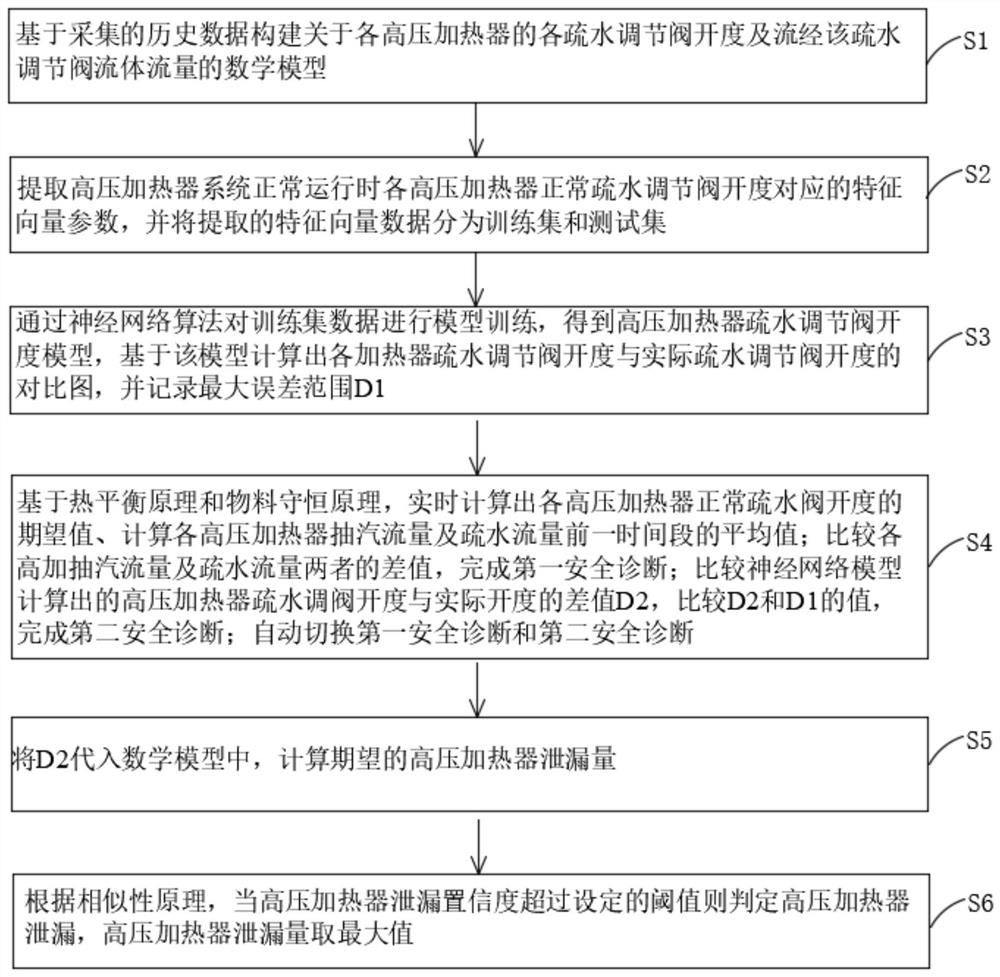

Method and system for diagnosing leakage fault of high-pressure heater based on neural network and thermodynamic modeling

A technology for high-pressure heaters and thermodynamic modeling, which is applied in neural learning methods, biological neural network models, and testing of machine/structural components. It can save investment and later maintenance costs, improve safety and economy, and reduce throttling losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

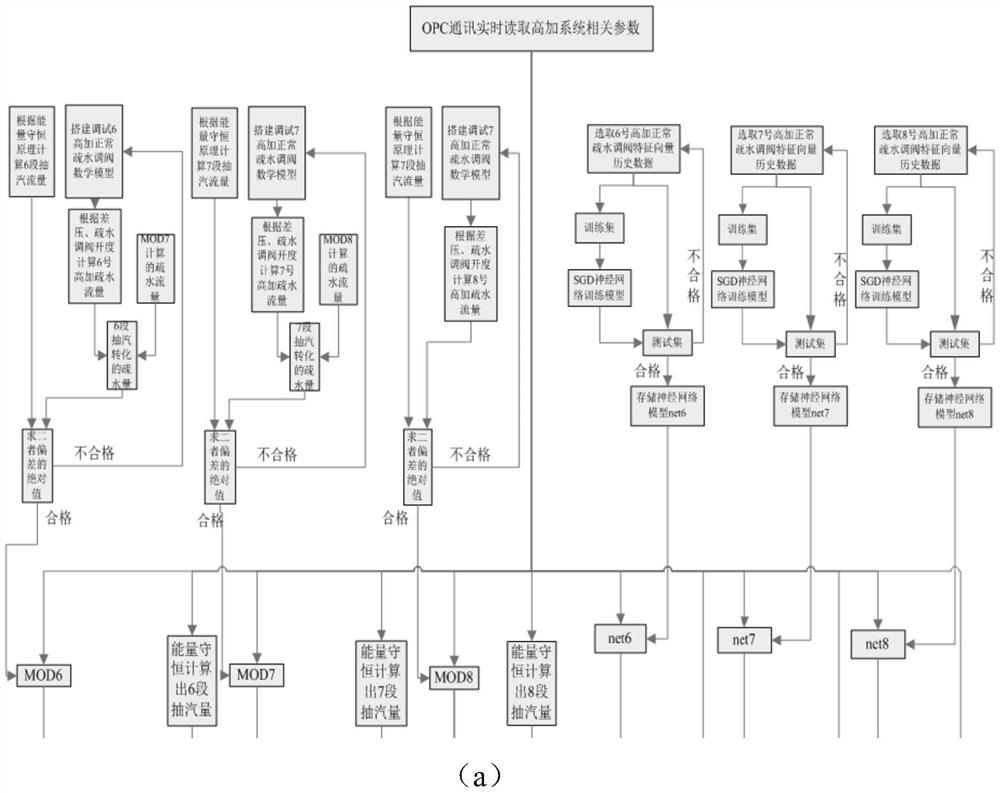

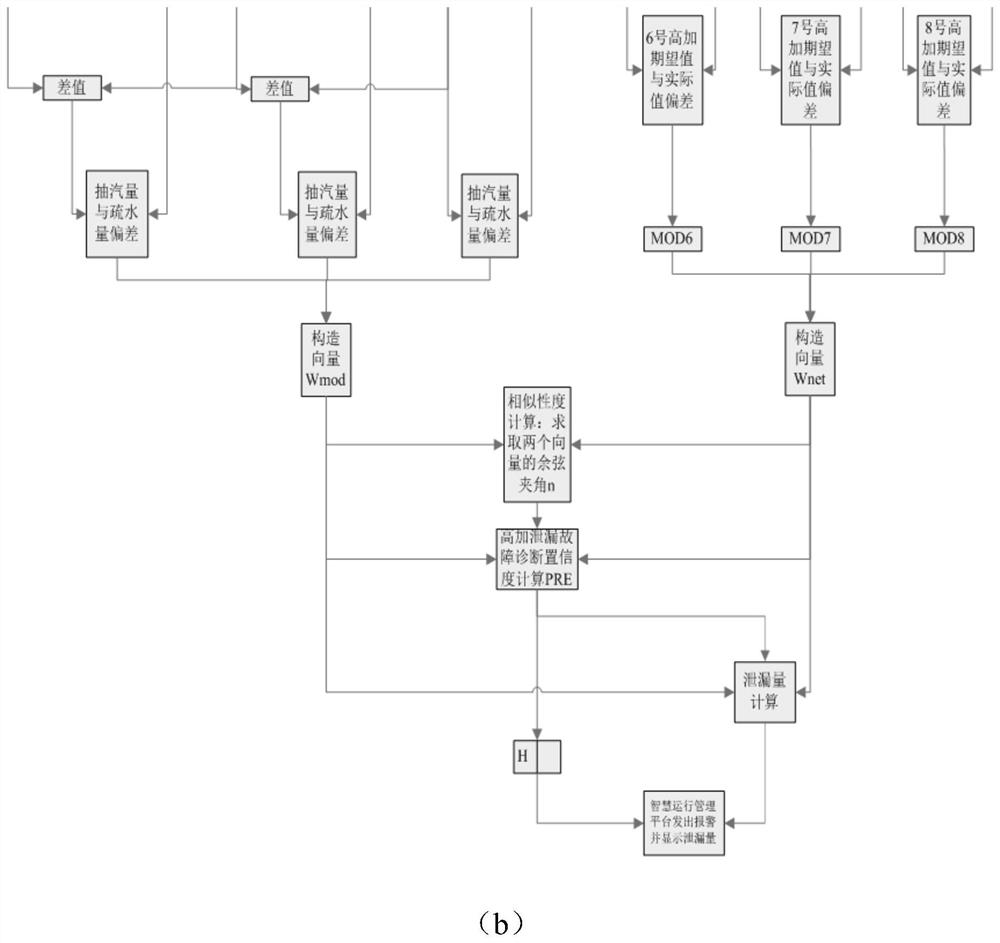

[0067] Such as figure 2 As shown in (a)(b), taking the steam turbine unit of Huaneng Dalian Power Plant as an example, the high-pressure heater (high-pressure heater) is 8 / 7 / 6 sections. The number and number of high-pressure heaters of different units are different, but they can all be used The method provided in this embodiment.

[0068] Step 1. Calculate the extraction steam flow rate of the 8 / 7 / 6 section under the normal working condition of the high-pressure heating system through the principle of heat balance.

[0069] Step 2. Using the principle of fluid mechanics, the volumetric flow rate flowing through the pipeline in a turbulent state is linearly related to the square root of the differential pressure on both sides of the pipeline. The Reynolds coefficient of a circular smooth pipeline is about 2500, and the Reynolds coefficient of a high-pressure drain pipeline will increase significantly after being throttled by a drain valve and perennial corrosion. Substitute t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com