Insulator defect automatic detection algorithm for electric power inspection video

A power inspection and automatic detection technology, which is applied in the direction of calculation, measurement devices, computer components, etc., can solve problems such as damage to the service life of transmission lines, dirt, power outages, etc., to solve unrobust problems and low computational complexity , the effect of high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

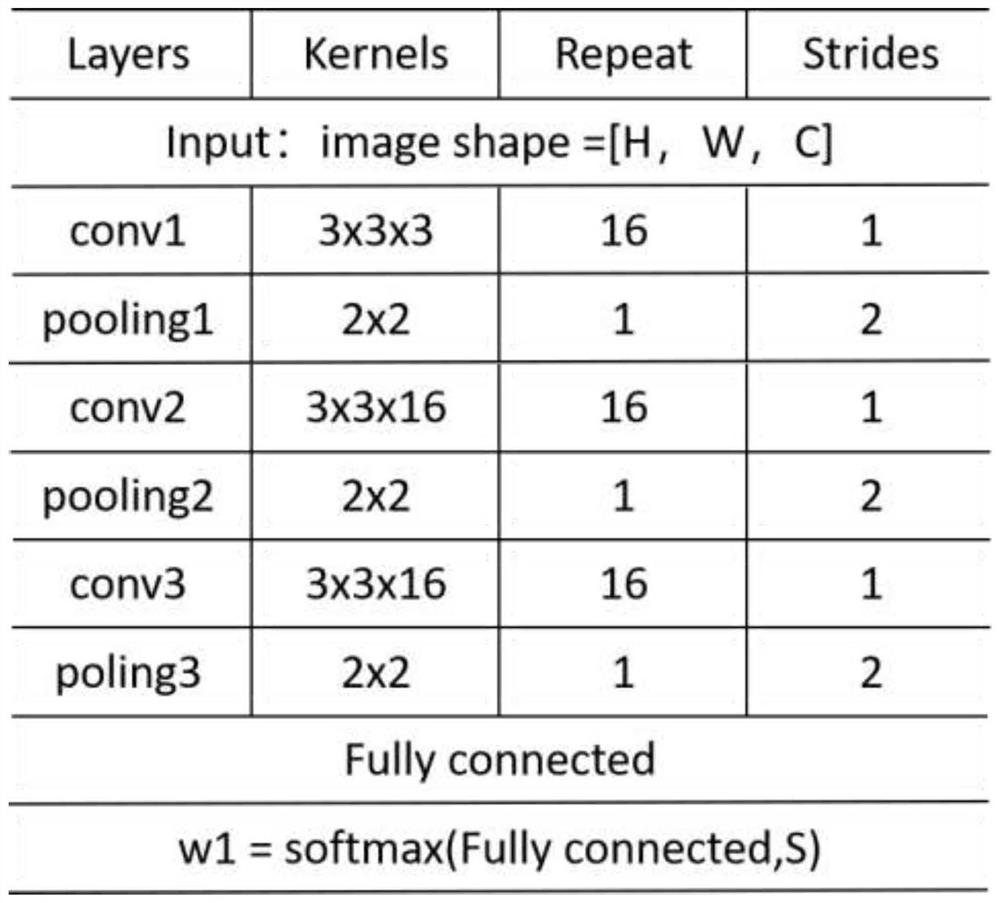

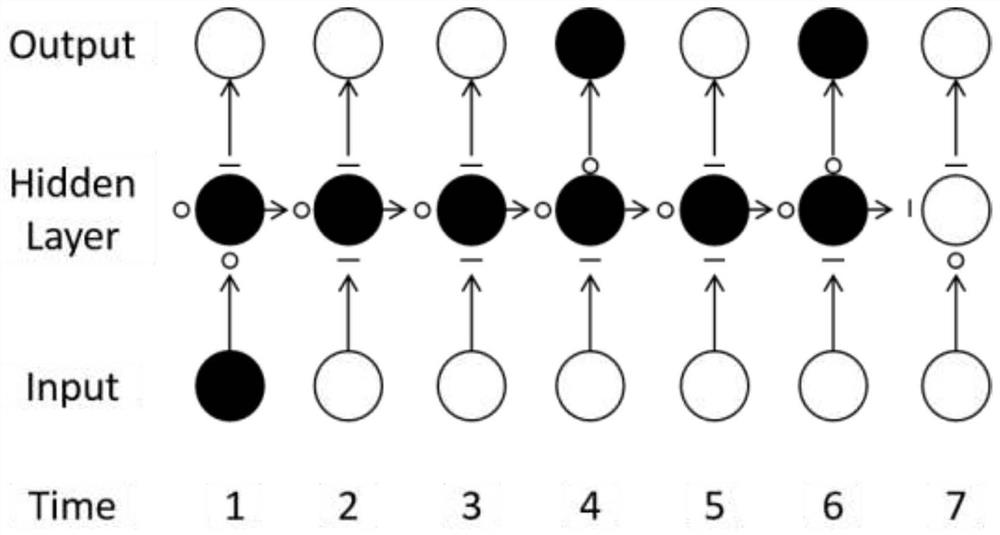

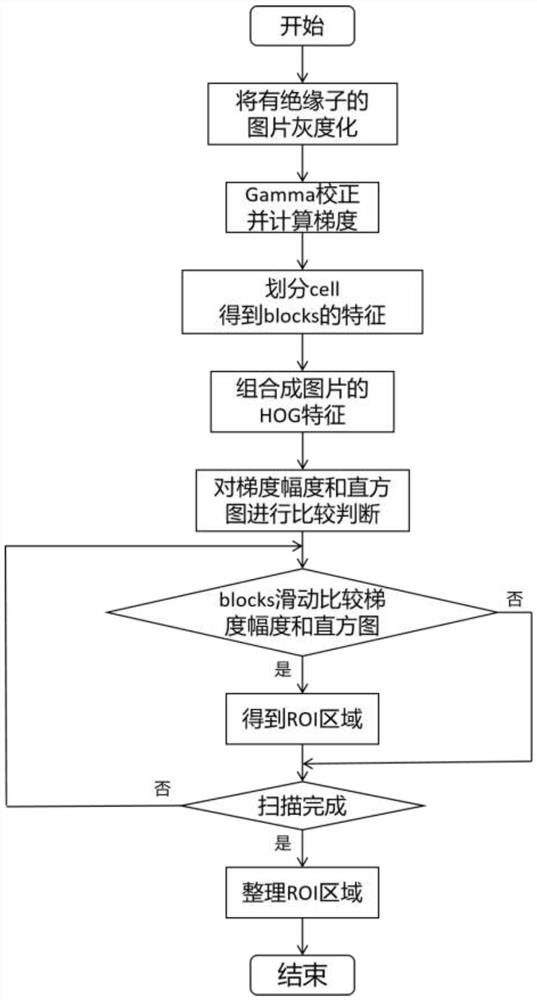

[0072] The invention provides an automatic detection algorithm for insulator defects oriented to power inspection video, such as figure 2 and Figure 5 As shown, the specific steps are as follows:

[0073] Step 1, classify and enhance the original power tower insulator sample data:

[0074] Extract the existing sample data of power tower insulators, get the original sample image, divide the data into two categories: with insulators and without insulators, and divide them into test set data and training set data;

[0075] Call the image processing library in the python environment, define the enhancement factor, and perform data enhancement on the original image: data flipping, data rotation, data amplification, data cropping, data translation, noise perturbation, etc., through data enhancement, you can get a lot different from the original...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com