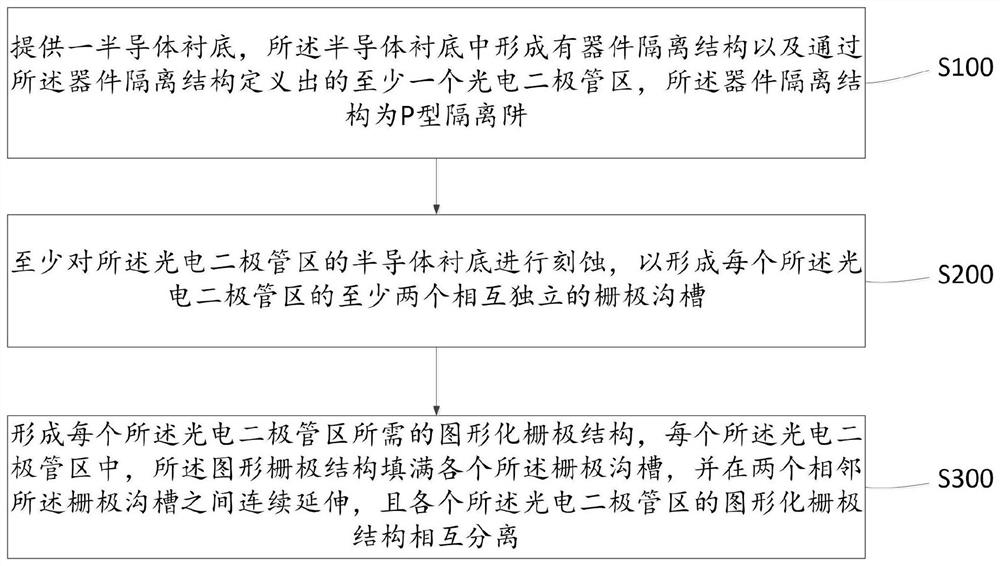

Image sensor and forming method of image sensor pixel structure

An image sensor and pixel structure technology, applied in the field of semiconductors, can solve the problems of low electron transmission rate deep in the photodiode, small surface channel and vertical channel path, etc., to increase the area of electron transmission and communication, reduce electron residue, The effect of increasing the transport rate of photogenerated electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

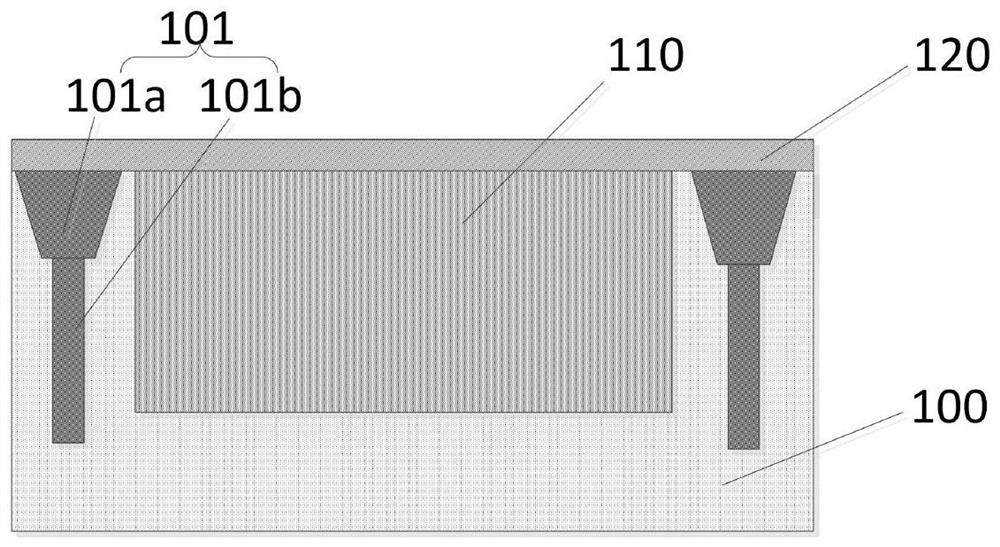

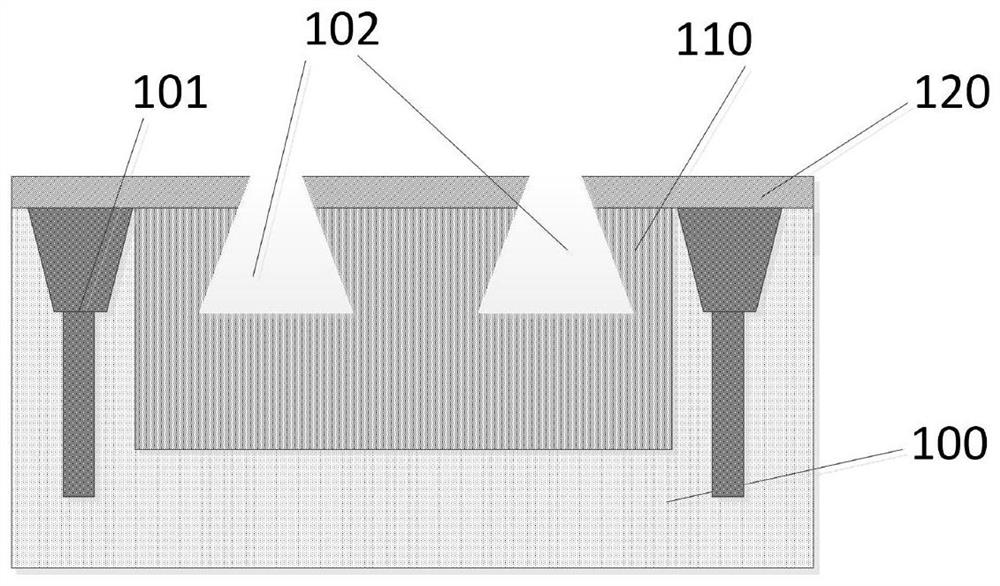

[0040] As mentioned in the background art, for an image sensor with a small pixel, since the pixel is small, photons are converted into fewer electrons, and the charge in the full well is on the order of thousands. At present, the surface channel and the vertical channel are relatively small in the way of electron transmission, and the transmission of electrons deep in the photodiode needs to pass through the entire junction region, which is easy to be recombined, resulting in low extraction efficiency. Moreover, electrons deep in the P-N junction need a certain amount of time and voltage to complete the transmission, which is not conducive to fast reading.

[0041] For this reason, the present invention provides a method for forming an image sensor pixel structure to solve the problem that the surface channel electricity and vertical channel electron transmission paths in the image sensor pixel structure are relatively small, resulting in low electron transmission rates deep i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com