Double-layer carbon coating-metal selenide composite electrode material and preparation method thereof

A metal selenide, composite electrode technology, applied in active material electrodes, negative electrodes, battery electrodes, etc., can solve the problems of long preparation cycle, complex preparation process, poor cycle stability and rate performance, etc., to improve electrical conductivity, The effect of good overall performance, improved stability and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

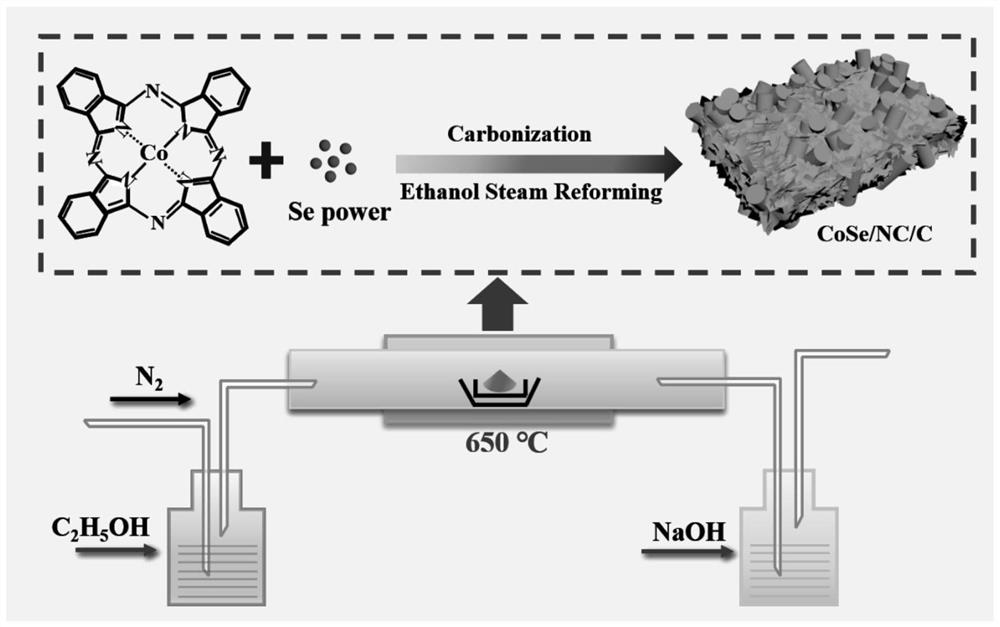

[0034] Preparation of C-coated-COSe / NC composite material, the preparation process is as follows figure 1 shown.

[0035] (1) Accurately weigh 0.2 g of cobalt phthalocyanine and 0.4 g of selenium powder and place them in a mortar, grind them for 20 minutes to mix them evenly, and then transfer the mixed powders to a quartz boat.

[0036] (2) Put the quartz boat into the tube furnace and heat it to 270°C at a heating rate of 4°C / min. After 15 minutes, heat it to 650°C at a heating rate of 5°C / min while passing a constant flow rate of 73sccm Nitrogen gas and ethanol vapor were blown into the tube furnace for a full reaction for 5 hours. After cooling to room temperature, the obtained black powder was washed with deionized water and dried in an oven to obtain a COSe / NC / C composite material.

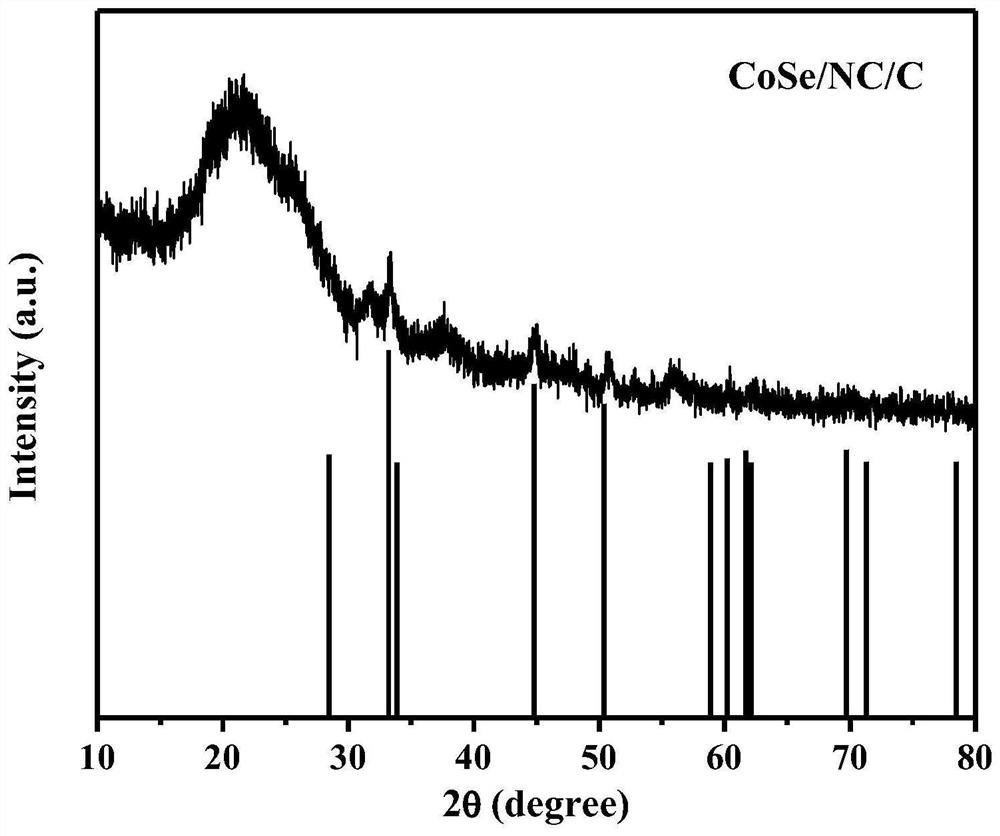

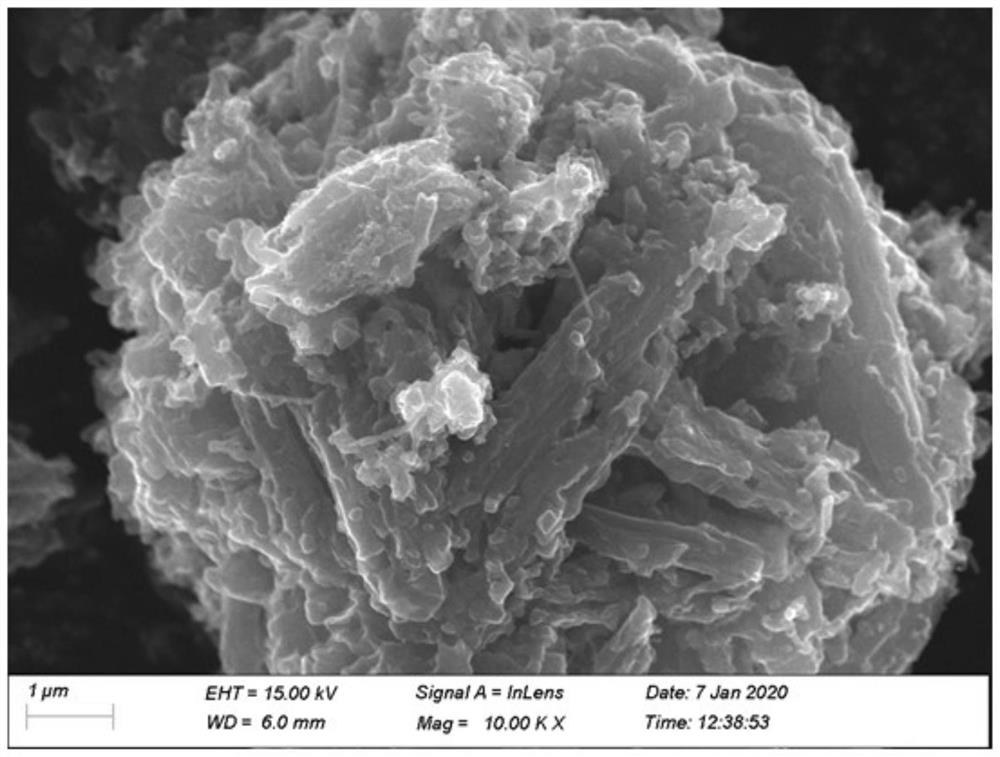

[0037] The obtained COSe / NC / C composite was characterized by X-ray diffraction, and the results were as follows: figure 2 Shown; Carry out the scanning electron microscope characterizatio...

Embodiment 2

[0040] (1) Accurately weigh 1.0 g of iron phthalocyanine and 1.4 g of selenium powder in a mortar, grind for 22 minutes to mix them evenly, and then transfer the mixed powder to a quartz boat.

[0041] (2) Put the quartz boat into the tube furnace and heat it up to 280°C at a heating rate of 5°C / min. After 20 minutes, heat it up to 800°C at a heating rate of 5°C / min, and at the same time pass a constant flow rate of 75sccm The nitrogen gas blows ethanol vapor into the tube furnace to fully react for 4.5 hours. After cooling to room temperature, the obtained black powder is washed with deionized water and dried in an oven to obtain a double-layer carbon-coated-metal selenide compound. electrode material.

[0042] The obtained double-layer carbon-coated-metal selenide composite electrode material was made into a button battery, and its performance was tested with a battery test system. Under the current density of 1000mA / g, the discharge specific capacity reached 621mAh / after 4...

Embodiment 3

[0044] (1) Accurately weigh 1.0 g of nickel phthalocyanine and 1.5 g of selenium powder in a mortar, grind for 30 min to mix them evenly, and then transfer the mixed powder to a quartz boat.

[0045] (2) Put the quartz boat into the tube furnace and heat it to 300°C at a heating rate of 3°C / min. After 20 minutes, heat it to 750°C at a heating rate of 4°C / min, and pass a constant flow rate of 78sccm at the same time. The nitrogen gas blows ethanol vapor into the tube furnace to fully react for 5 hours. After cooling to room temperature, the obtained black powder is washed with deionized water and dried in an oven to obtain a double-layer carbon-coated-metal selenide compound. electrode material.

[0046] The obtained double-layer carbon-coated-metal selenide composite electrode material was made into a button battery, and its performance was tested with a battery test system. Under the current density of 1000mA / g, the discharge specific capacity reached 678mAh / after 400 cycles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap