Pole piece forming device and battery cell production system

A technology for forming devices and pole pieces, which is applied in the direction of assembling battery machines, electrochemical generators, circuits, etc., can solve problems such as difficult to meet the needs of battery preparation, achieve the effect of reducing energy consumption and increasing the lamination speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

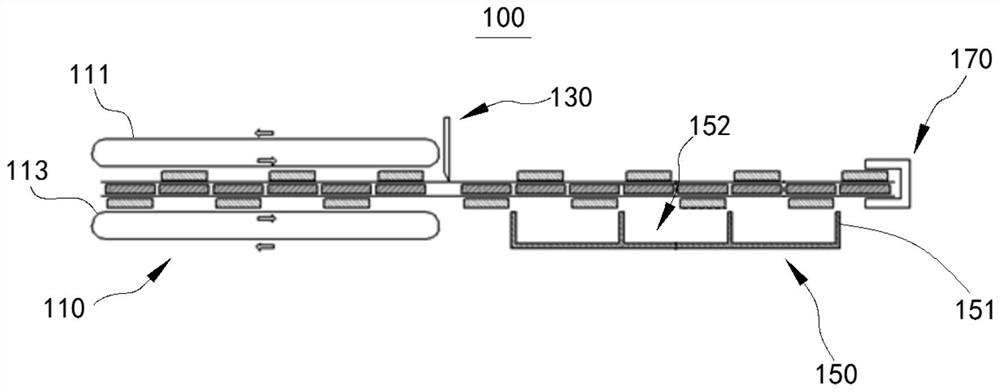

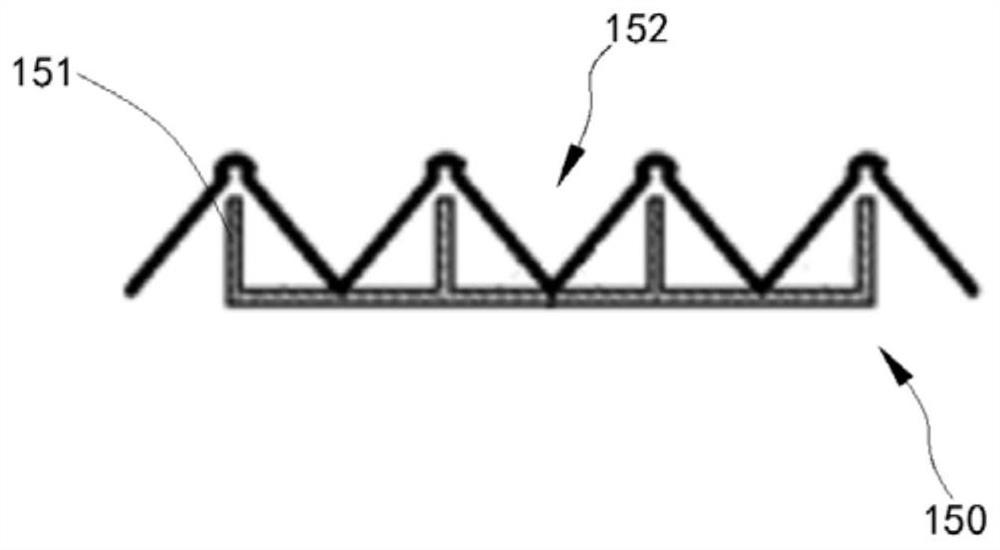

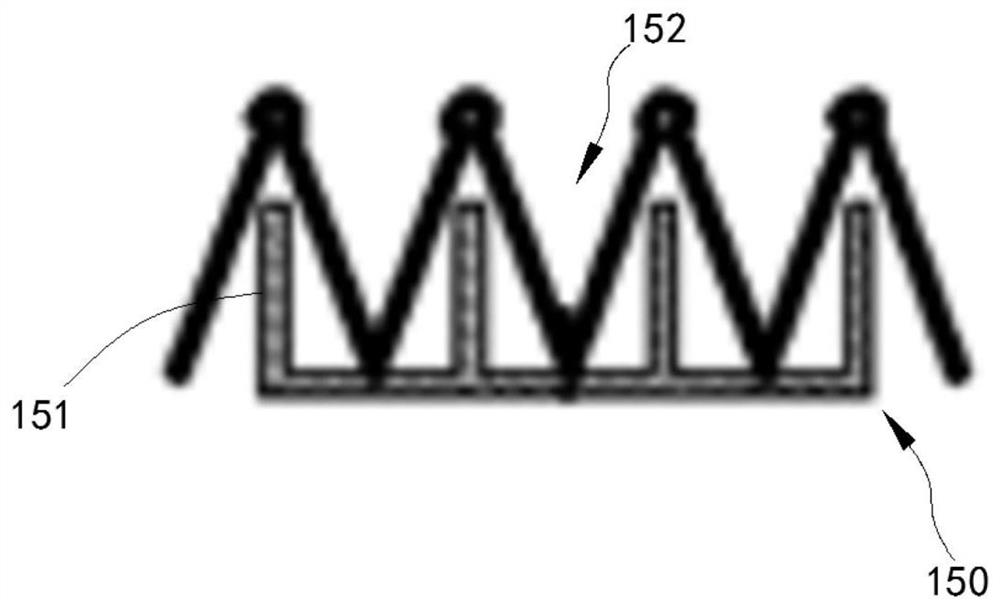

[0031] Please refer to figure 1 As shown, the pole piece forming device 100 provided in this embodiment is used for the stacking process in the battery manufacturing process, and the pole piece forming device 100 increases the stacking speed while reducing energy consumption.

[0032] The pole piece forming device 100 provided in this embodiment includes a controller (not shown in the figure), a conveying mechanism 110, a cutting mechanism 130, a forming mechanism 150 and a pulling mechanism 170, a conveying mechanism 110, a cutting mechanism 130 and a forming mechanism 150 are arranged sequentially in the first horizontal direction, the conveying mechanism 110 is used to clamp the composite unit pole piece and transport the composite unit pole piece along the first horizontal direction, and the pulling mechanism 170 is used to clamp the composite unit output by the conveying mechanism 110 pole piece, and pull the composite unit pole piece along the first horizontal direction ...

no. 2 example

[0050] This embodiment provides a cell production system, including the pole piece forming device 100 provided in the first embodiment. The pole piece forming device 100 passes through the level Arrangement, and through the coordinated control of the controller, the preliminary folding of the composite unit pole piece is realized by using gravity, which realizes the energy-free lamination, and the cut part of the composite unit pole piece is formed at one time, which is extremely efficient.

[0051] Therefore, the cell production system provided by this embodiment has higher lamination efficiency and lower energy consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com