Wet dust removal device for steelmaking slag braising smoke dust

A technology of wet dust removal and wet dust collector, applied in the direction of combination device, separation method, chemical instrument and method, etc., can solve the problems of reducing the floor space, shortening the treatment process of the dust removal system, failing to meet the dust emission standards, etc., to prevent dust The effect of hardening and saving fresh water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

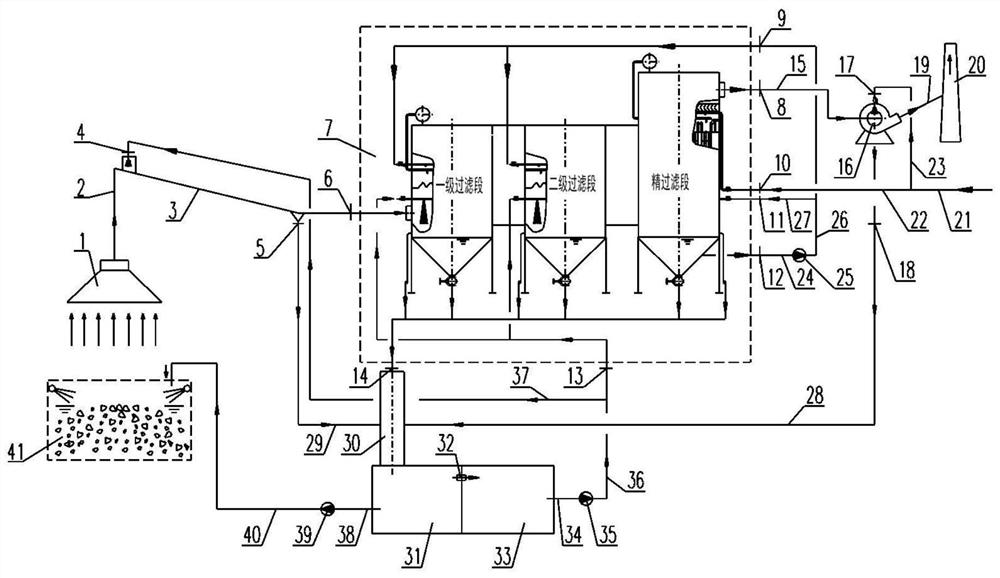

Method used

Image

Examples

Embodiment 1

[0024] A method for using a wet dust removal device for steelmaking slag dust, the specific steps and parameters are as follows:

[0025] 1. First run the water supply system of the device. The water quality of the water supply system is industrial clean ring water. It is divided into two branches, all the way into the 7 fine filter section of the wet dust collector, and a water film is formed on the surface of the metal filter bag to realize the water film and metal filter. Double filtration of bags, when the steelmaking slag wet dust removal device system handles an air volume of 50,000m 3 / h, the water supply is 20t / h, and the water spray pressure is ≥0.2MPa; the other channel is used to clean the impeller of the fan 16 to ensure the smooth operation of the fan, the water supply is 2t / h, and the water spray pressure is ≥0.2MPa. The impeller cleaning sewage of the blower fan 16 is cleaned by the blower blower blower 18, flows into the main drainage ditch 30 through the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com