Recoverable functional joint with high-strength steel column, common steel beam and low-yield-point steel angles

A low-yield point steel and recovery function technology, which is applied in the field of high-strength steel columns-common steel beams-low yield point steel angle steel restoreable function nodes, which can solve the problem of large end shear force, inability to quickly disassemble and replace angle steel, beam-column Problems such as poor node recoverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

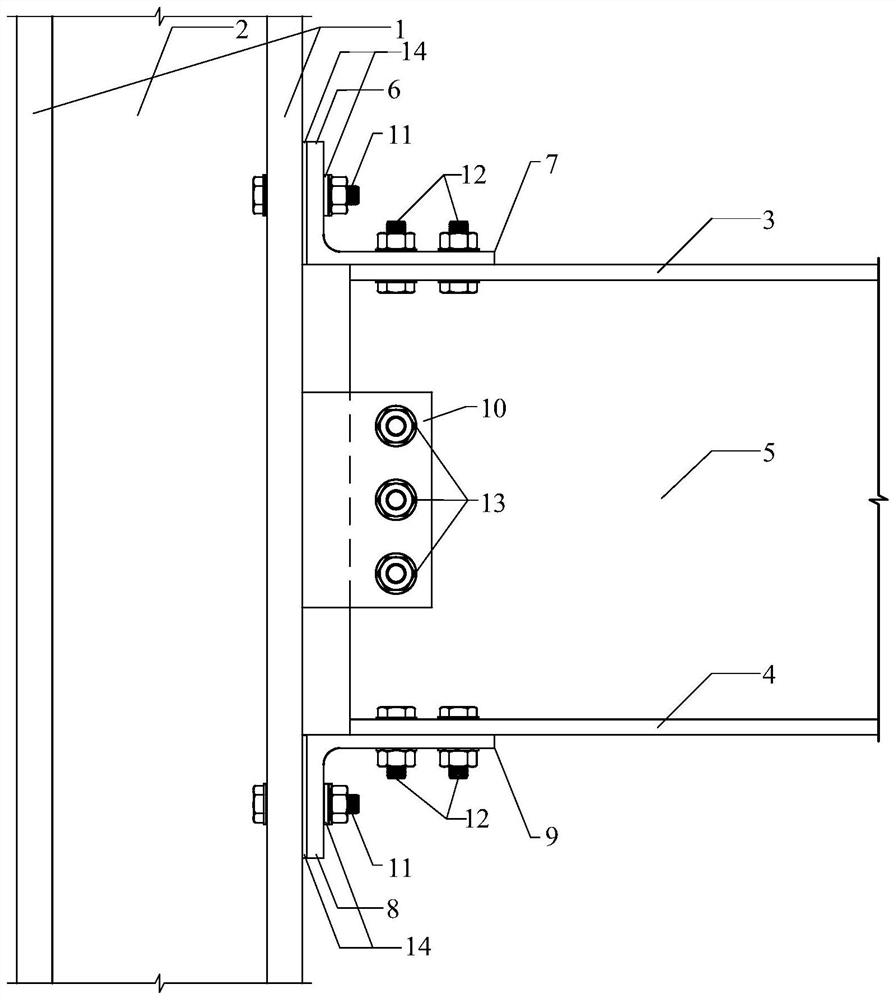

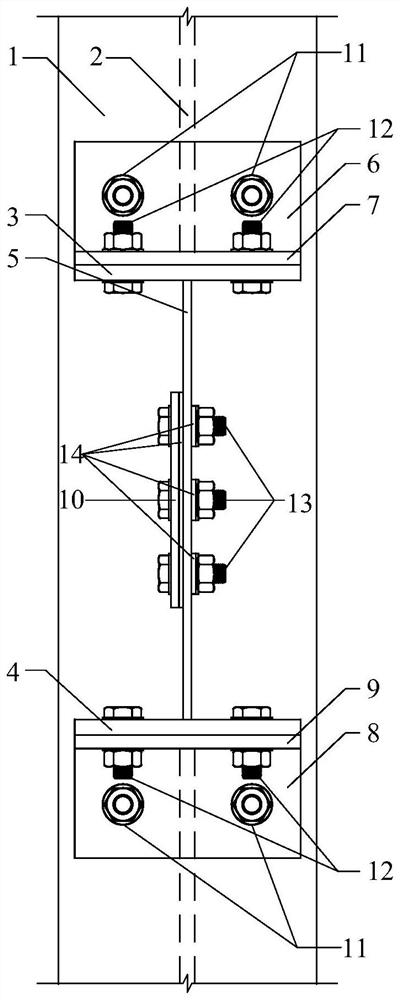

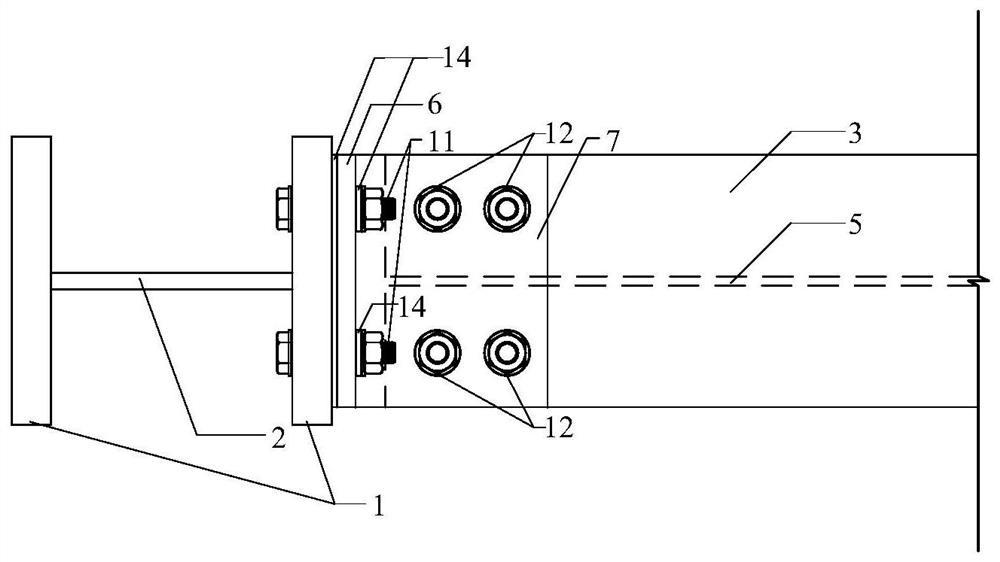

[0049] Such as Figure 1-Figure 9 As shown, the high-strength steel column-ordinary steel beam-low yield point steel angle steel recoverable function node, including the I-shaped high-strength steel column, the I-shaped ordinary steel beam, the first angle steel and the second angle steel of low yield point steel, and the connection Plate 10 , first bolt 11 , second bolt 12 and third bolt 13 .

[0050] The first angle steel and the second angle steel are rolled or welded, and LYP100, LYP160, LYP225 or Q235 steel with low yield point is used to ensure its energy dissipation capacity. The other limb 7 is formed, and the second angle steel is made up of one limb 8 of the second angle steel and the other limb 9 of the second angle steel; the first angle steel is arranged above the second angle steel, and the other limb 7 of the first angle steel and the other One limb 9 is arranged in parallel.

[0051] The beam adopts Q355, Q390 or Q420 ordinary steel to meet the necessary bear...

Embodiment 2

[0079] The difference between this embodiment and embodiment 1 is:

[0080] Such as Figure 10-Figure 14 As shown, the shear member adopts two third angle steels, one limb 15 of the two third angle steels abuts against the flange 1 of the high-strength steel column, and the other limbs 16 of the two third angle steels are respectively arranged on two sides of the web 5 of the ordinary steel beam. Side and clamp the common steel beam web 5. The two third angle steel limbs 15 have a fifth through hole 24 in advance in the factory, and the high-strength steel column flange 1 has a sixth through hole 25 in the factory in advance, which can be passed through the fifth through the fourth bolt 17 in the factory or on site. The through hole 24 and the sixth through hole 25 connect the two third angle steels and the high-strength steel column. The fourth bolt 17 is a high-strength bolt. The other limbs 16 of two 3rd angle steels have the second through hole 21 in factory in advance, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com