Rock wall crane beam concrete temperature control method, device and system

A technology of concrete and crane beams, which is applied in the processing of building materials, construction, building construction, etc., and can solve problems that affect structural safety and excessive cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

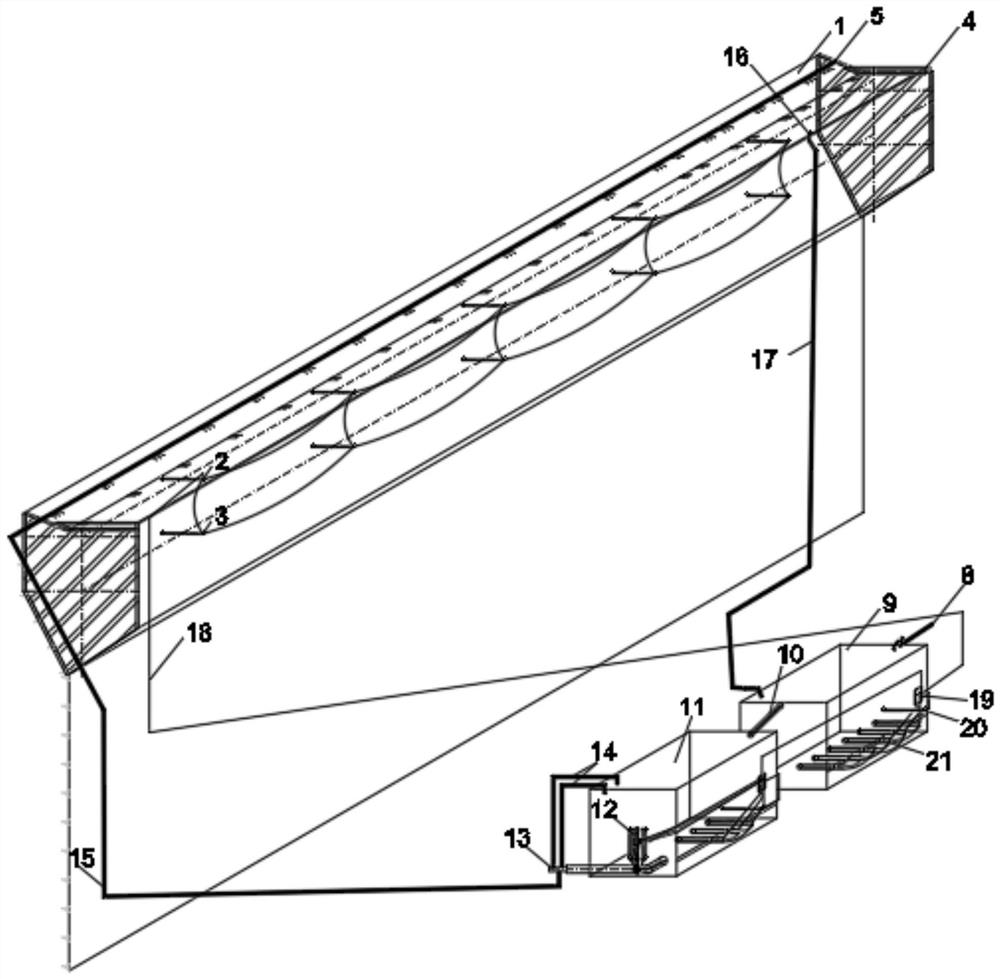

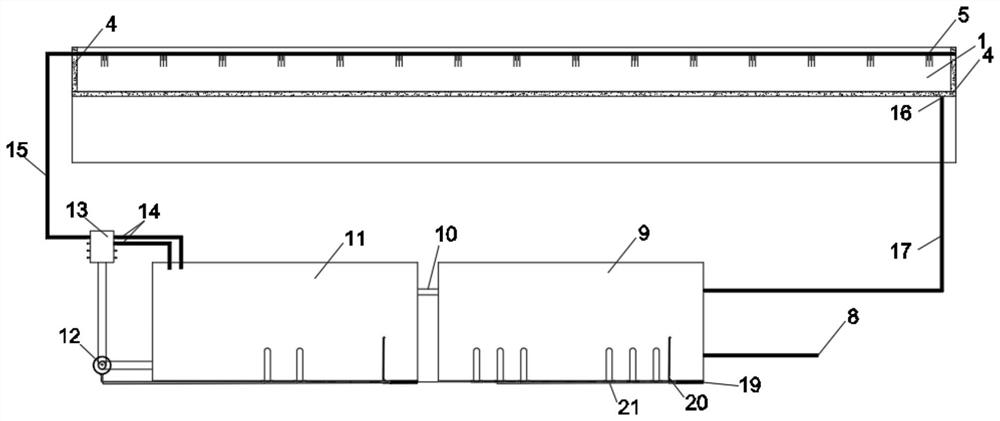

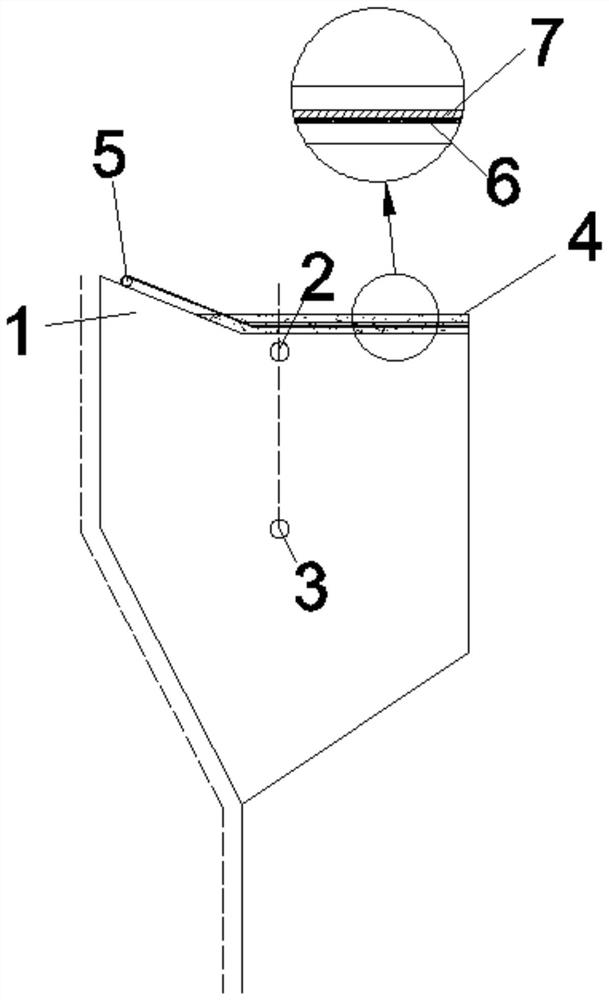

[0034] refer to Figure 1 to Figure 3 , the embodiment of the present application provides a rock wall crane beam concrete temperature control system, the rock wall crane beam concrete 1 includes several warehouses of concrete, and the temperature control system includes a temperature measurement mechanism, a warm water circulation mechanism and a warm shed mechanism;

[0035] The temperature measuring mechanism includes a surface thermometer 2 and a central thermometer 3, the surface thermometer 2 is buried on the central section of each warehouse concrete and close to the upper surface of each warehouse concrete, and the central thermometer 3 is buried in the center of the central section of each warehouse concrete Location;

[0036] Further, the NZWD type resistance thermometer is embedded in the rock wall crane beam concrete 1 before pouring. Resistance thermometers are suitable for long-term buried in or on the surface of hydraulic structures or other geotechnical struct...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap