Method for designing components of high-entropy alloy based on electronic alloy theory

A technology for high-entropy alloy and composition design, which is applied in design optimization/simulation, calculation, data processing application, etc., and can solve problems such as the inability to effectively guide the composition design of high-entropy alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

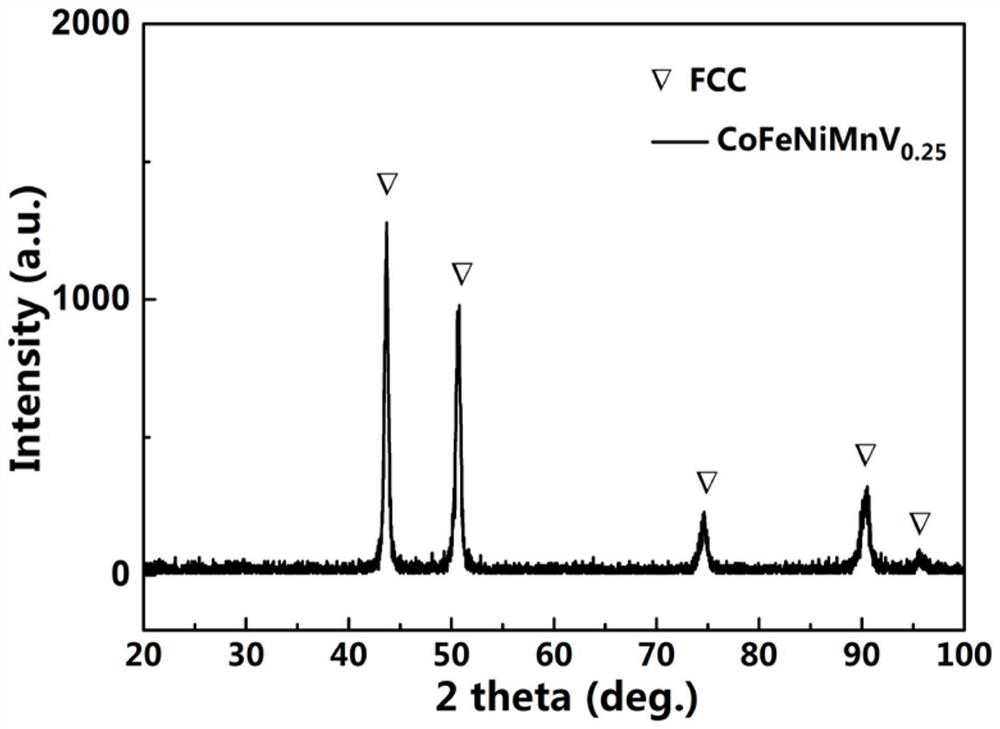

[0033] A method for designing high-entropy alloy components based on electronic alloy theory, the steps of which are:

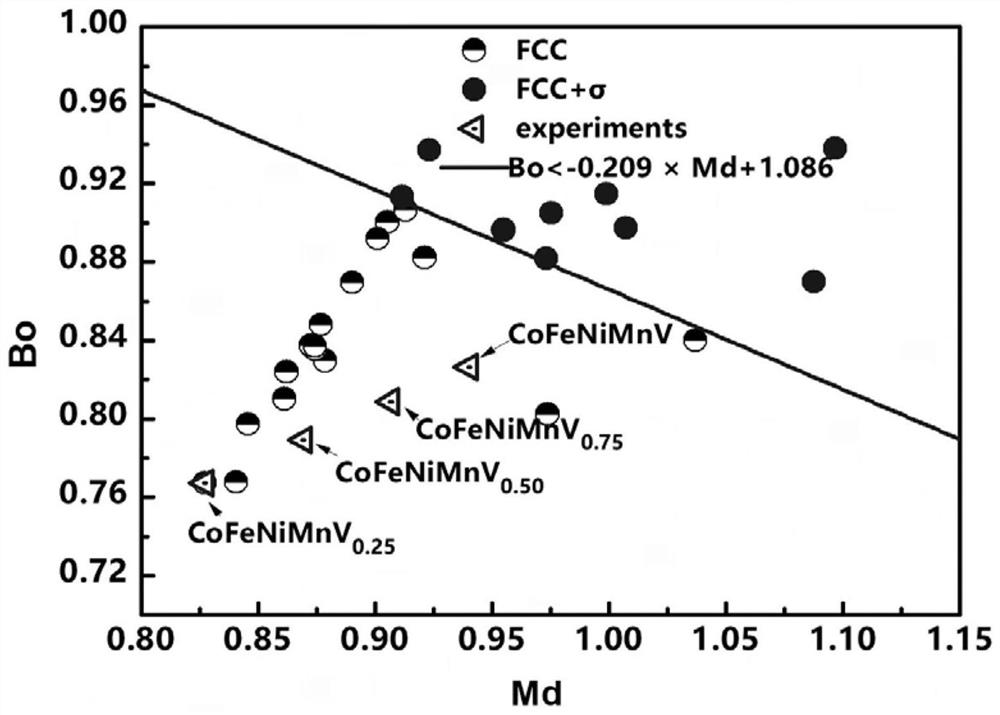

[0034] (1) The target high-entropy alloy is CoFeNiMnV 0.25 , using the cluster method to calculate the target high-entropy alloy CoFeNiMnV 0.25 The average Md value of and average Bo value

[0035] (2) Obtain the phase structure of the target high-entropy alloy according to the relationship between the average Md value and the average Bo value, specifically:

[0036] Therefore: The target high-entropy alloy should be FCC single phase in the as-cast state;

[0037] (3) Obtain the atomic percentage of each component according to the phase structure and expression of the target high-entropy alloy (specifically: Co 23.53% , Fe 23.53% 、Ni 23.53% , Mn 23.53% , V 5.88% ) after converting it into weight percent;

[0038] (4) Weigh each component by weight percentage, adopt vacuum smelting method to melt each component under the protection of inert gas ...

Embodiment 2

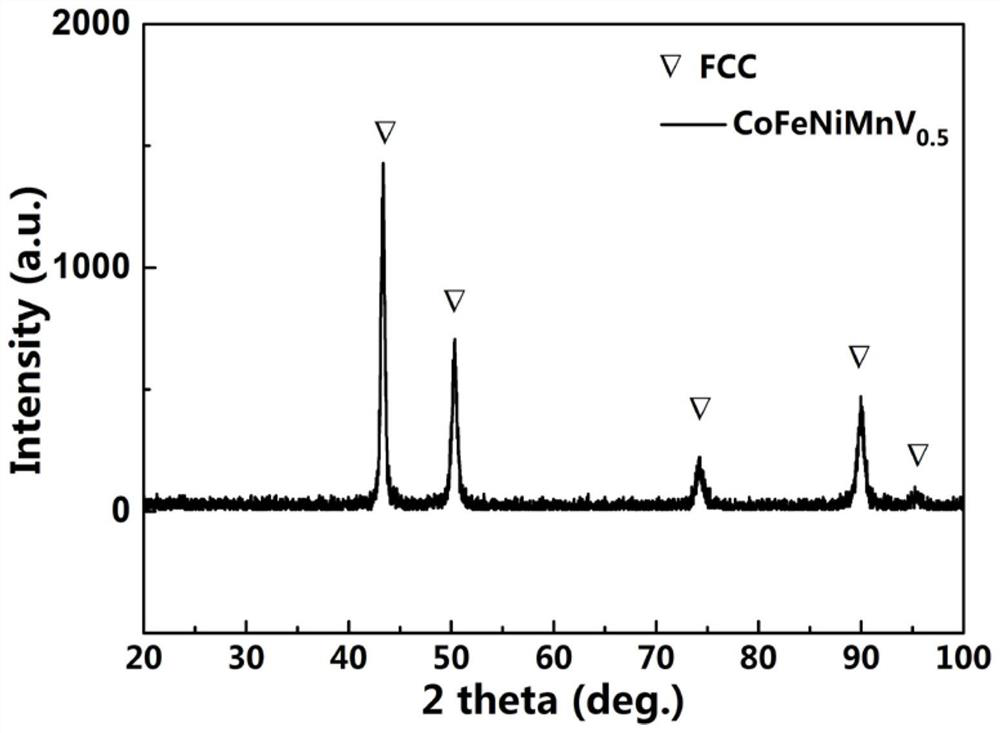

[0041] A method for designing high-entropy alloy components based on electronic alloy theory, the steps of which are:

[0042] (1) The target high-entropy alloy is CoFeNiMnV 0.5 , using the cluster method to calculate the average Md value of the target high-entropy alloy CoFeNiMnV0.25 and average Bo value

[0043] (2) Obtain the phase structure of the target high-entropy alloy according to the relationship between the average Md value and the average Bo value, specifically:

[0044] Therefore: The target high-entropy alloy should be FCC single phase in the as-cast state;

[0045] (3) Obtain the atomic percentage of each component according to the phase structure and expression of the target high-entropy alloy (specifically: Co 22.22% , Fe 22.22% 、Ni 22.22% , Mn 22.22% , V 11.11% ) after converting it into weight percent;

[0046] (4) Weigh each component by weight percentage, adopt vacuum smelting method to melt each component under the protection of inert gas t...

Embodiment 3

[0049] A method for designing high-entropy alloy components based on electronic alloy theory, the steps of which are:

[0050] (1) The target high-entropy alloy is CoFeNiMnV0.75, and the average Md value of the target high-entropy alloy CoFeNiMnV0.25 is calculated by the cluster method and average Bo value

[0051] (2) Obtain the phase structure of the target high-entropy alloy according to the relationship between the average Md value and the average Bo value, specifically:

[0052] Therefore: The target high-entropy alloy should be FCC single phase in the as-cast state;

[0053] (3) Obtain the atomic percentage of each component according to the phase structure and expression of the target high-entropy alloy (specifically: Co 21.05% , Fe 21.05% 、Ni 21.05% , Mn 21.05% , V 15.79% ) after converting it into weight percent;

[0054] (4) Weigh each component by weight percentage, adopt vacuum smelting method to melt each component under the protection of inert gas t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com