Turbine mortise shot blasting discrete element-finite element coupling multi-scale simulation method

A simulation method and finite element technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of limited number of times, inability to test shot peening parameters, and high test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

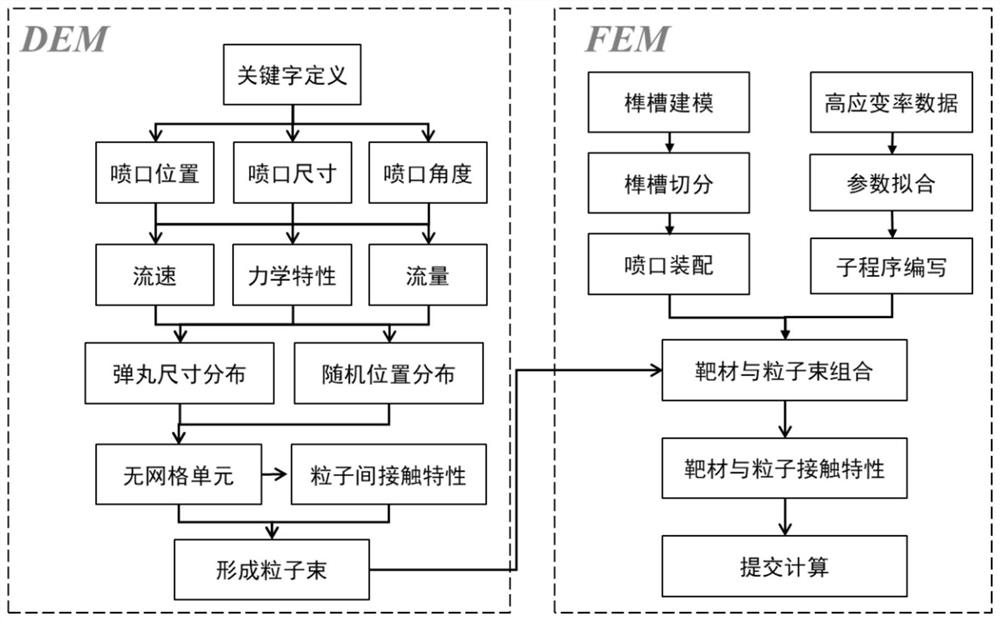

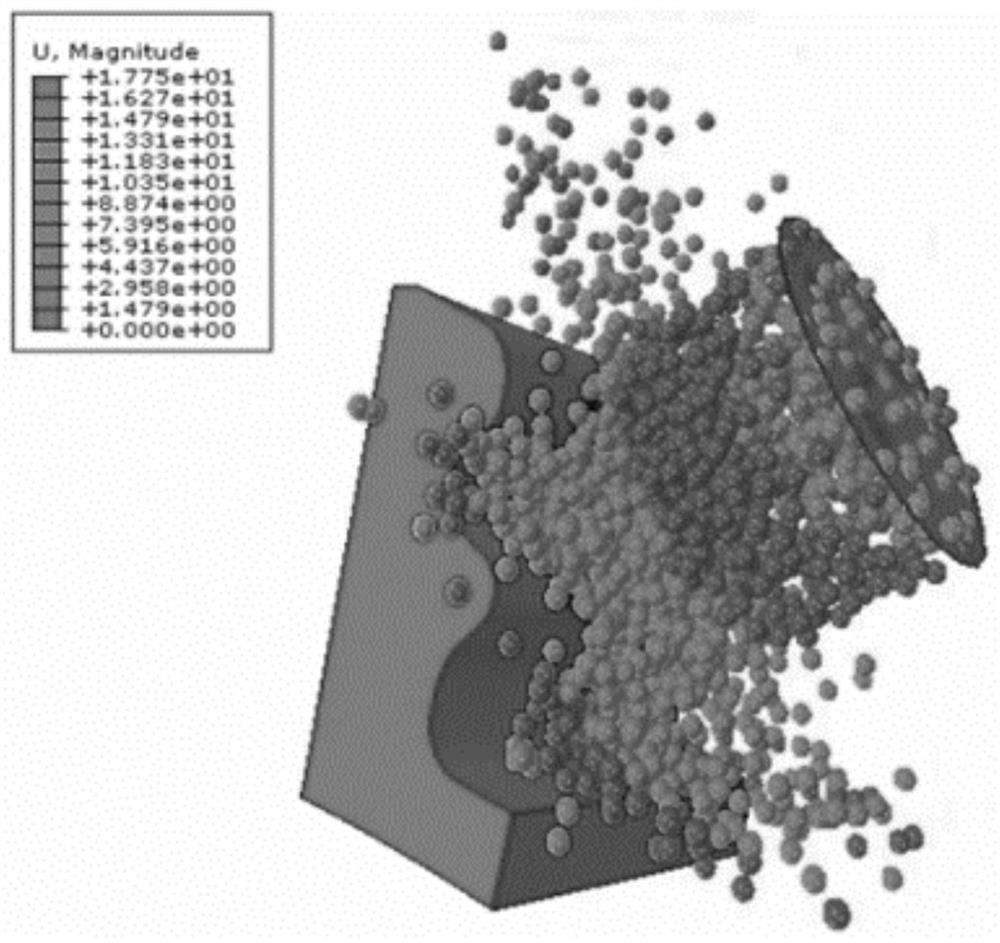

[0024] The following is a further description of the technical solution of a discrete element-finite element coupling multi-scale simulation method for shot peening of a turbine tenon-groove structure according to the present invention by way of example in conjunction with the accompanying drawings. The pre-study material in this example is nickel-based superalloy GH4169. Such as figure 1 As shown, a kind of turbine tenon-groove structure shot peening strengthening discrete element-finite element coupling multi-scale simulation method of the present invention is specifically implemented as follows:

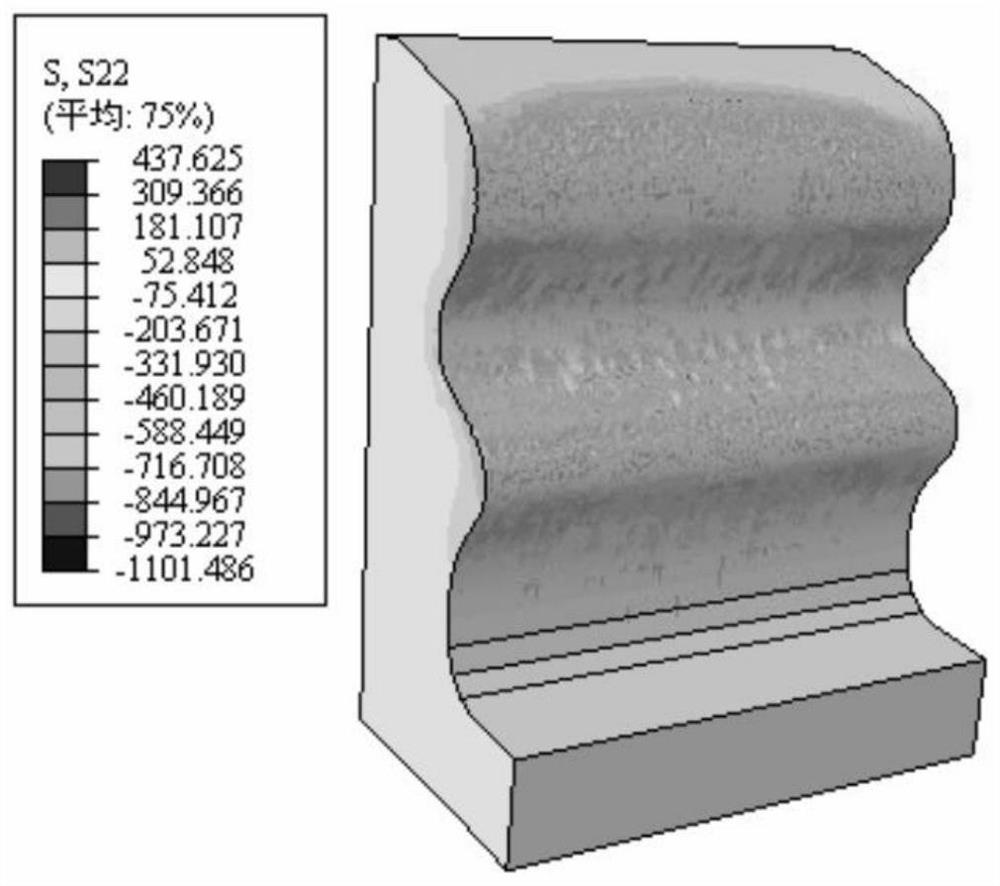

[0025] The first step is to cut the tongue-and-groove structure to be studied according to the symmetry of the tongue-and-groove model, and endow it with a high strain rate constitutive model. The high strain rate constitutive model refers to that the strain rate in the shot peening process reaches 10 3 ~10 5 / s, the constitutive model used needs to reflect the stress-strain be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com